6.7.2 Mounting the block holder in the work-

ing chamber

If you only want to machine blocks in 1 block holder,

directly mounting the block holder in the working

chamber is faster than using the blank changer.

1. Open the working chamber door.

2. Open the blank holder by selecting the

depicted icon in the Machining view in

DENTALCNC.

3. Remove the blank in the blank holder if any.

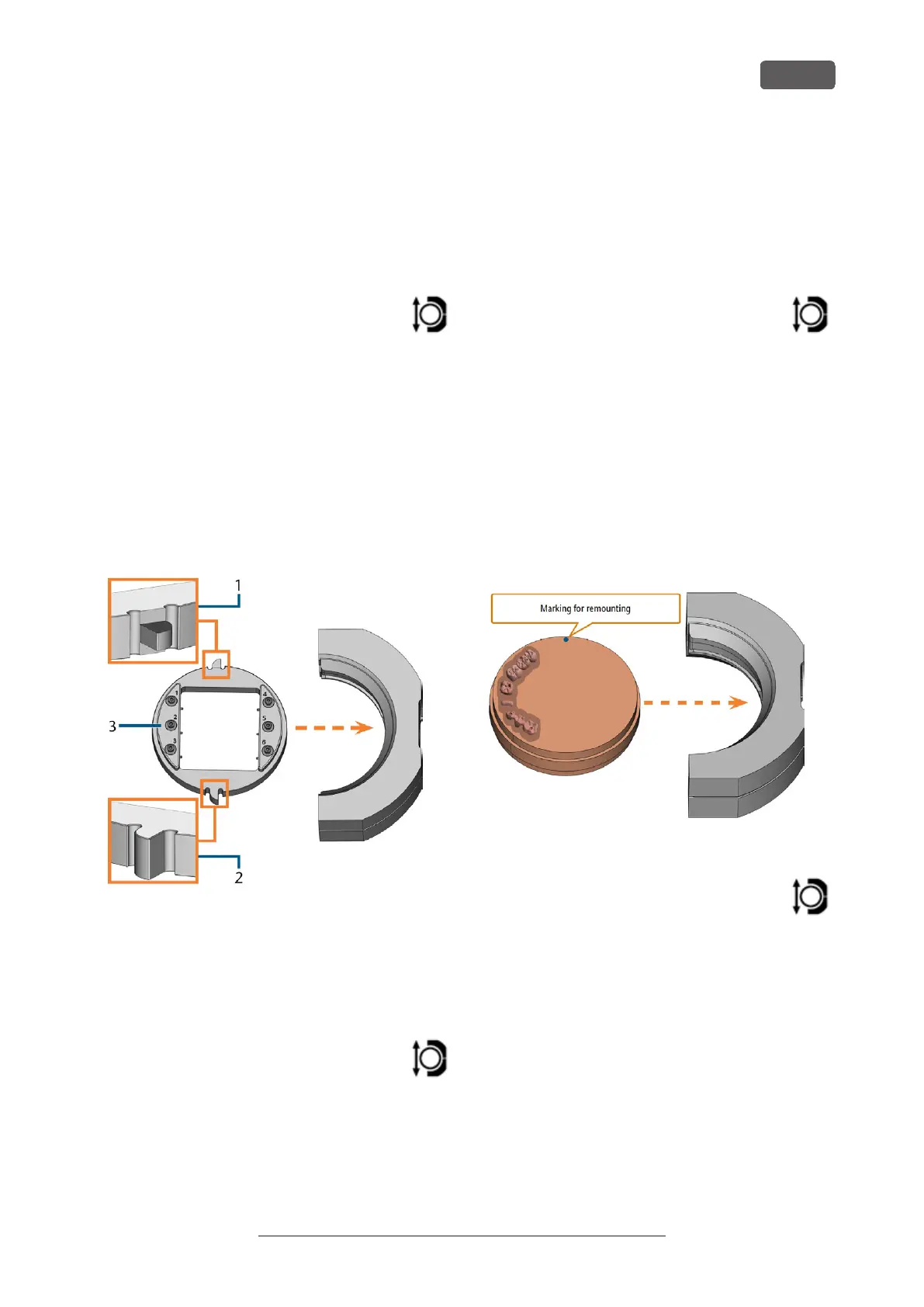

4. Correctly orient the block holder:

n

The numbers labeling the block positions

must face upwards.

n

The positioning aid with reduced height must

be positioned in the rear.

n

The positioning aid with full height must be

positioned in the front.

5. Push the block holder into the blank holder.

FIG. 48 INSERTING THE CORRECTLY ORIENTATED BLOCK HOLDER INTO

THE BLANK HOLDER

1. Rear positioning aid (reduced height)

2. Front positioning aid (full height)

3. Upper side of the block holder

6. Close the blank holder by selecting the

depicted icon in the Machining view in

DENTALCNC.

6.7.3 Mounting discs in the working cham-

ber

If you only want to machine 1 disc, directly mounting

the disc in the working chamber is faster than using

the blank changer.

1. Open the working chamber door.

2. Open the blank holder by selecting the

depicted icon in the Machining view in

DENTALCNC.

3. Remove the blank from the blank holder if any.

4. If the blank is a multilayer blank, orientate the blank

so that the top color layer is on top.

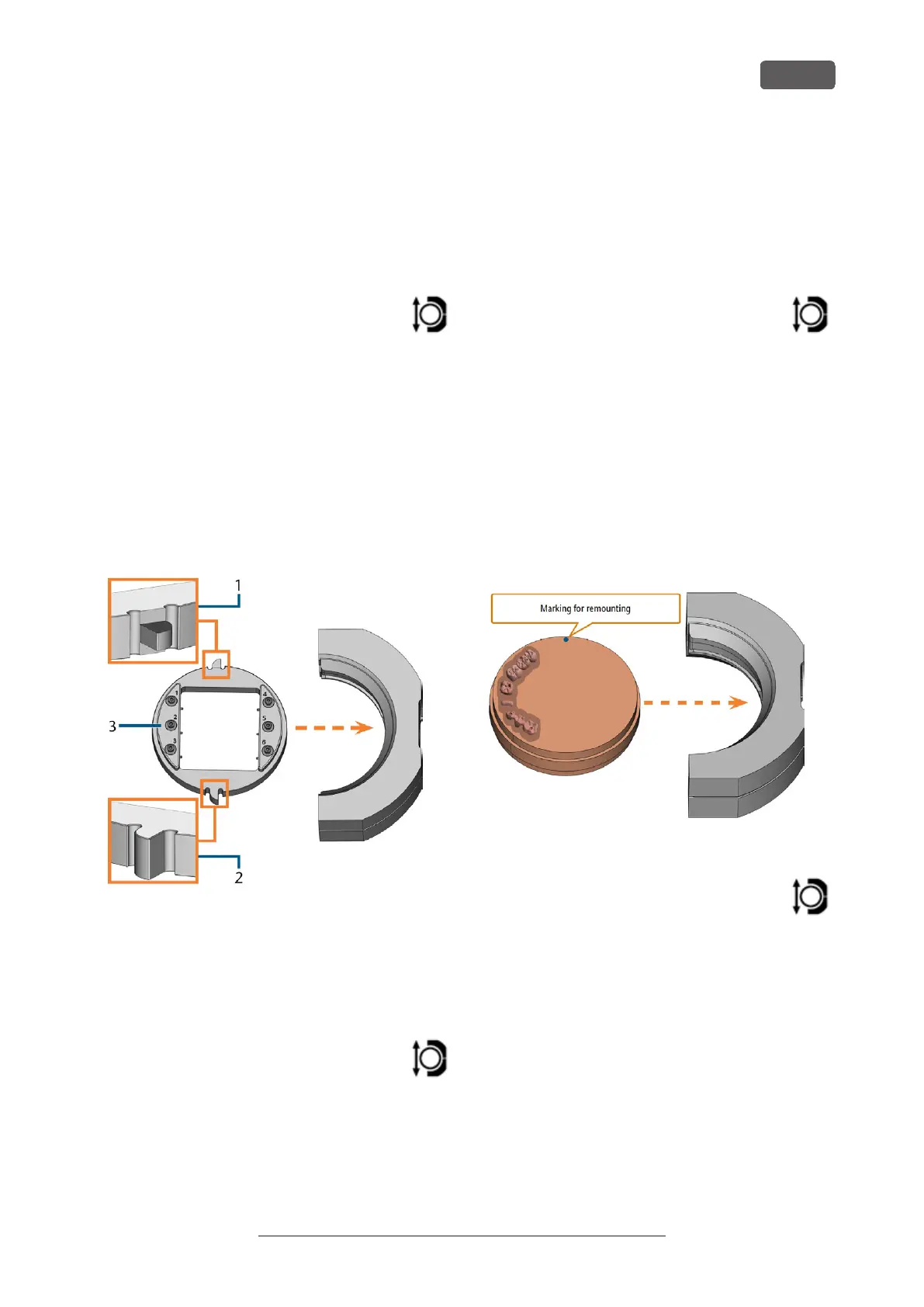

5. If the disc has been processed before, ensure the

following:

n

The original top side faces upwards.

n

If the disc has been marked for safer remount-

ing by DENTALCNC, ensure that the marking

is in the position shown below.

6. Push the disc into the blank holder.

FIG. 49 REMOUNTING AN ALREADY PROCESSED DISC TO THE BLANK

HOLDER (MARKINGS FOR SAFER REMOUNTING IN BLUE)

7. Close the blank holder by selecting the

depicted icon in the Machining view in

DENTALCNC.

R5 – Operation: Preparing jobs

EN 39

Original Operating Instructions:R5

Version: 12/16/2021

Loading...

Loading...