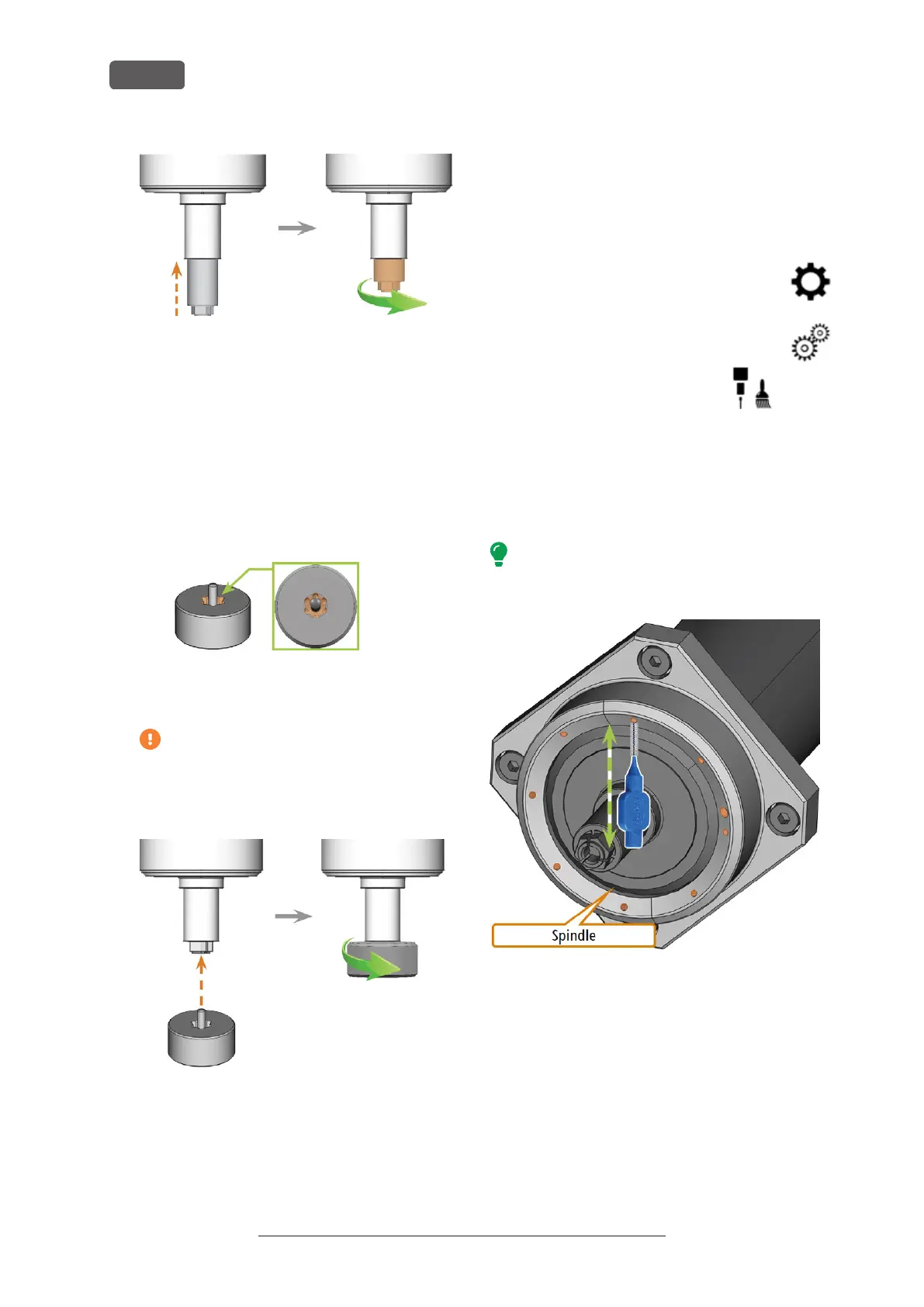

FIG. 88 SCREWING IN THE COLLET CHUCK (MARKED ORANGE IN THE

RIGHT ILLUSTRATION) INTO THE SPINDLE WITH YOUR HAND

16. Insert the pin of the knurled nut into the collet

chuck. Ensure that the collet chuck is properly

seated in the recess of the knurled nut.

17. Tighten the collet chuck with the knurled nut:

a. Insert the pin of the knurled nut into the col-

let chuck.

b. Ensure that the collet chuck fully sits in the

recess of the knurled nut.

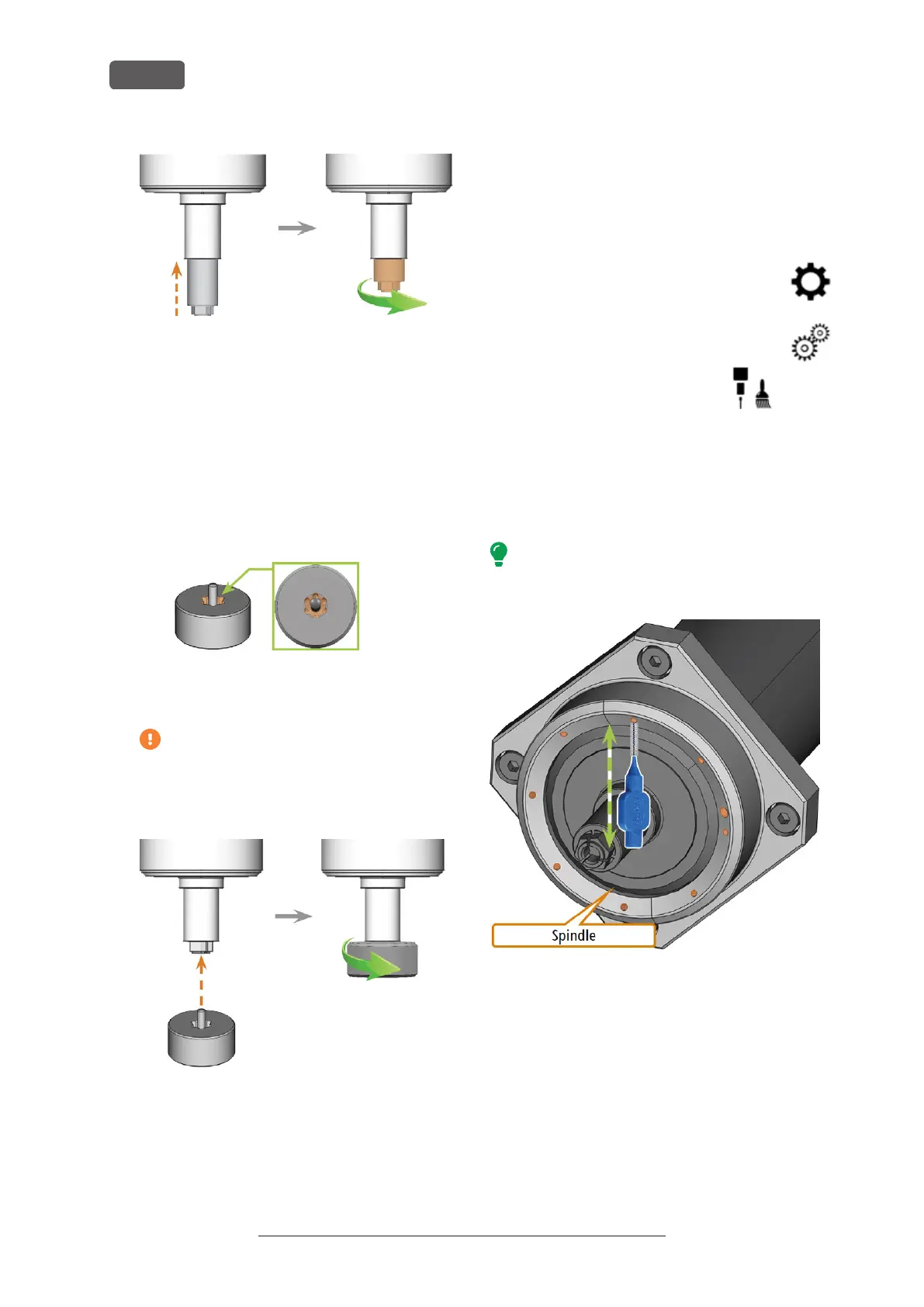

FIG. 89 RECESS IN KNURLED NUT (MARKED ORANGE)

c. Twist the knurled nut clockwise.

The collet chuck must be screwed in tightly.

Otherwise rotational imperfections can

occur during operation which will worsen

your processing results

FIG. 90 TIGHTENING THE COLLET CHUCK WITH THE KNURLED NUT;

RECESS IN KNURLED NUT MARKED ORANGE

18. Store the spindle service set in a safe place.

19. Close the working chamber door.

20. Clean the nozzle plate.

8.10 Cleaning the nozzle plate

You should clean the holes in the nozzle plate every

time you clean the collet chuck.

1. Have the interdental brush ready.

2. Open DENTALCNC‘s general application

settings with the depicted icon in the

main icon bar.

3. Open the Machine parameters view with

the depicted icon in the local icon bar.

4. Move the axes into the tool

change position by selecting

the depicted icon in the Machin-

ing view in DENTALCNC.

5. Open the working chamber door.

6. Clean the ring of 9 holes in the inner area of the

nozzle plate. For this, move the interdental brush

up and down.

If necessary, apply some water with a cleaning

agent and let it sit for some minutes.

FIG. 91 CLEANING THE NOZZLE PLATE; NOZZLES MARKED ORANGE

Original Operating Instructions:R5

Version: 12/16/2021

R5 – Maintenance and do-it-yourself

EN 60

Loading...

Loading...