11

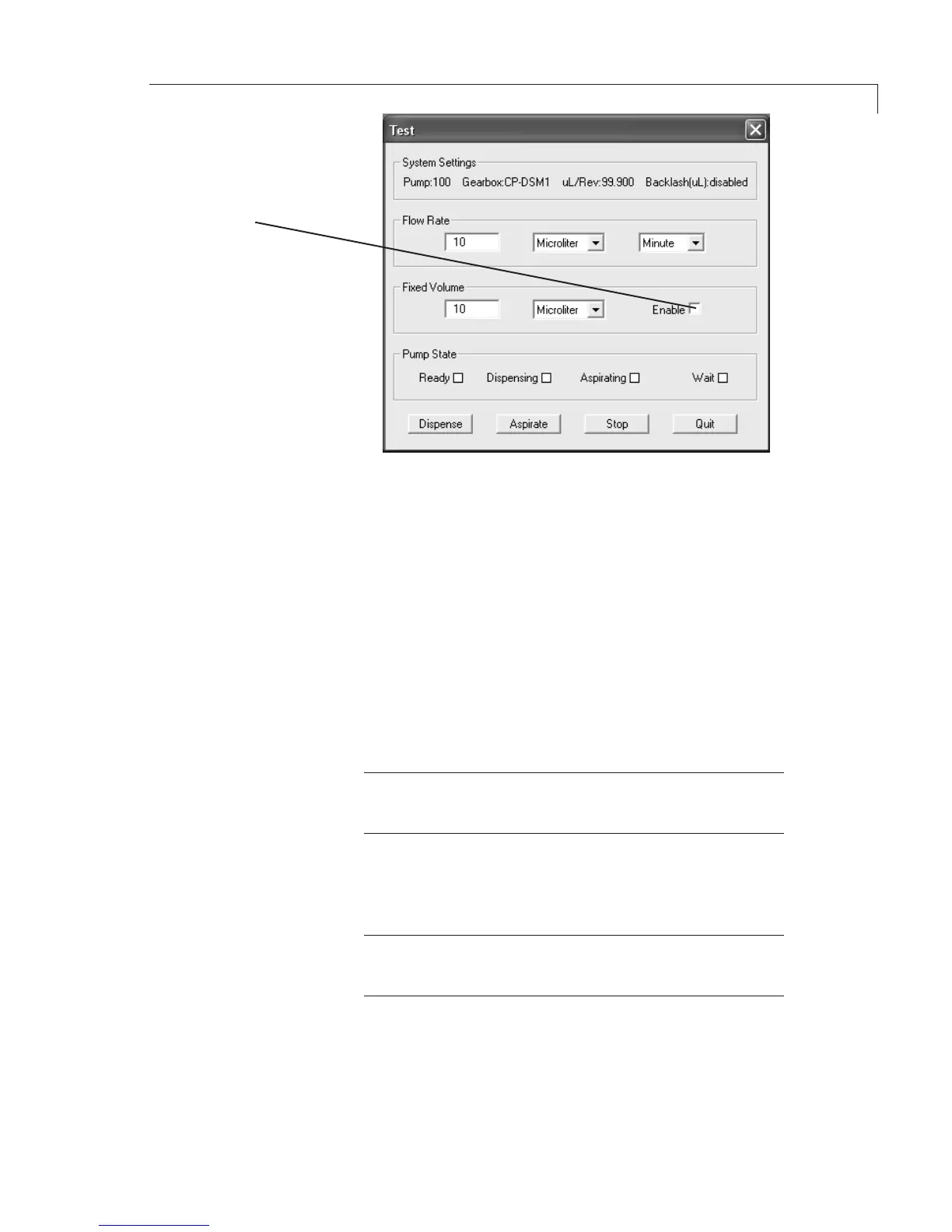

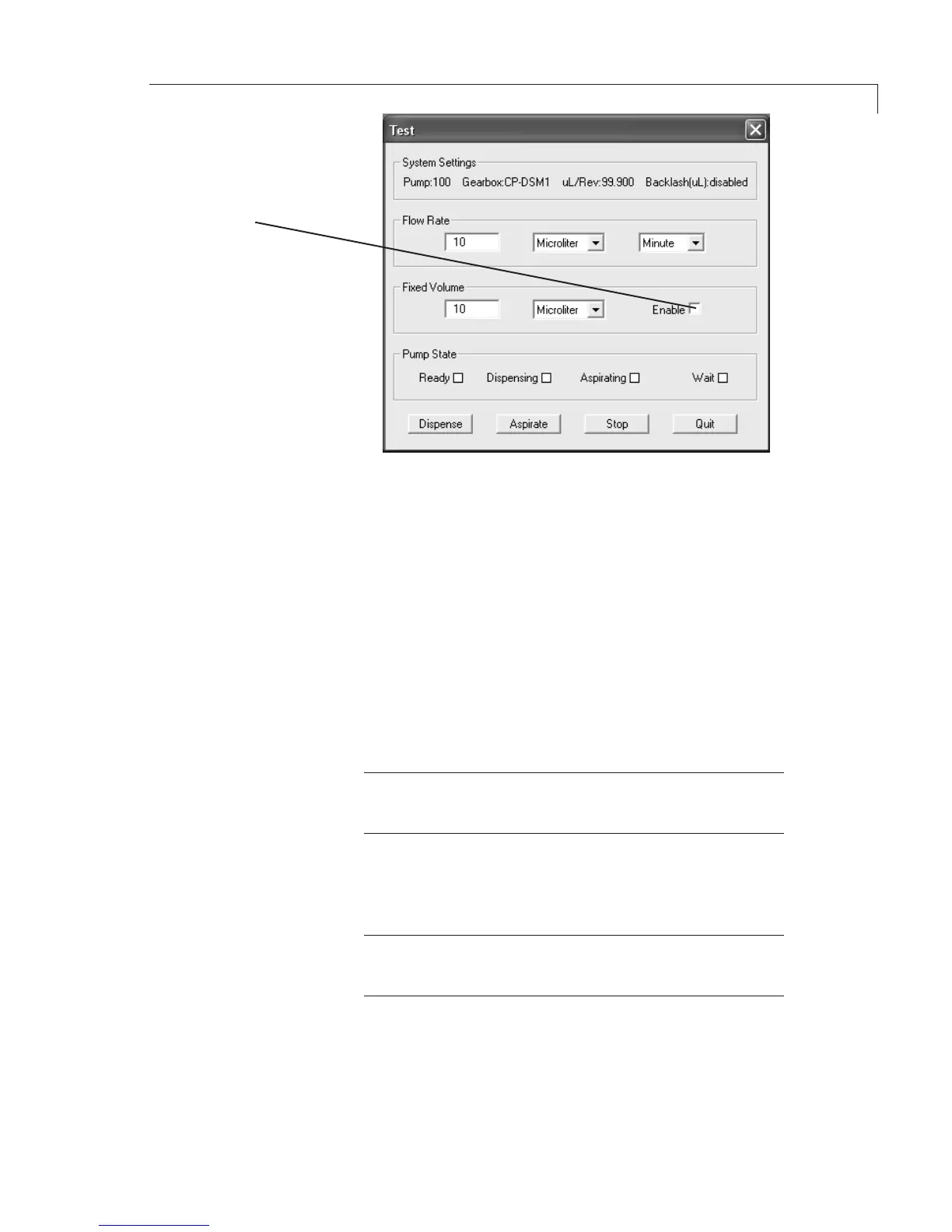

1. IfthescreeninFigure 9 is not already open, go to the main menu, and

choose Utility > Test.

2. IfthetubingIDis0.010”orless,enter

FlowRate: 200µL/min

FixedVolume: 1000µL

Click the Enable box

IfthetubingIDislargerthan0.010”,enter

FlowRate: 9000µL/min

FixedVolume: 1000µL

Click the Enable box

(In the Test Mode, user-entered flow parameters cannot be saved; when you

exit the program, these values will revert to defaults.)

NOTE:SmallerIDandlongerlengthtubingcancauseexcessive

restriction. Adjust flow rates accordingly. Maximum backpressure

is100psi.

3. ClicktheDispensebutton.Thedesignatedvolumeofisopropylalcohol

should move through the tubing and into the receiver bottle, removing

any air bubbles and priming the system. If it does, the pump is primed

and ready for use.

NOTE: If a buffer will be used, flush all the isopropyl alcohol out of

the lines by placing the inlet tube in a vessel of water, changing the

xedvolumeto2000µL,andclickingtheDispensebutton.

4. If the pump doesn’t seem to draw any isopropyl alcohol into the tubing:

(a) Check for leaks around the fittings and make sure the tubing is well

seated in the pump head.

(b) Make sure the end of the tubing is free to draw liquid into the pump.

(TIP:Cutthetipendthatgoesintotheisopropyl

alcohol reservoir at a 45° angle.)

(c) Touch the pump to make sure it is on.

Ifthepumpstilldoesn’tseemtofunctionproperly,consultthefactory.

Figure 9:PrimingthepumpintheTestMode(M6valuesshown)

CLICKTHEBOX

FOR A ONE TIME

FIXEDVOLUME

ASPIRATEOR

DISPENSE.

LEAVETHEBOX

UNCLICKEDFOR

CONTINUOUS

PUMPINGATTHE

ENTEREDFLOW

RATE.

Loading...

Loading...