10

Priming and Testing the Pump

At this stage, some basic tests will determine that the tubing connections are

tight and that the pump is rotating in the proper direction. The tests include an

initial priming of the pump to remove all air and unwanted solutions in the tubing.

Use proper safety precautions when pumping flammable

liquids. In all applications, make sure you have enough

tubing and sufficient quantities of solutions ready for

use before beginning a procedure.

Tubing Connections (M6 shown)

M6pumpsshouldnotbeusedwithtubingODssmallerthan1/16".ForM50

pumps,theminimumODis1/8".

Improperly installed fittings can create space for a

bubble to become trapped, degrading pump performance.

The use of non-VICI fittings can also adversely affect

pump function and performance.

1. Connectalengthoftubingtotheinlet(PortA)andplacetheotherendin

a vessel containing isopropyl alcohol.

2. Connectasecondlengthoftubingtotheoutlet(PortB)andplacethe

other end into a receiver bottle.

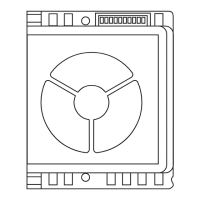

Fitting Assembly Instructions

1. Slidethenutandferruleonto

the tubing in the order shown.

2. Insert this assembly into the

fitting detail, screwing the nut in

two or three turns by hand.

3. Pushthetubingallthewayforwardintothedetailsothatitseatsrmly.

This is essential for a proper zero dead volume connection.

4. Turn the nut into the detail until it is finger tight.

Initial Priming

In the Test Mode, a mouse click on a button directs the pump to either

aspirate or dispense. (Refer to page 13, No. 7 for a definition, if required.)

WhentheEnableboxintheFixedVolumeareaischecked,(seeFigure 8)

thepumpwillaspirateordispensethequantityenteredintheFixedVolume

field and then stop. If the Enable box is not selected, the pump will continue

to run at the set Flow Rate until either Stop (stops aspirating or dispensing)

orQuit(exitstheTestMode)isselected.

If the pump aspirates a volume larger than the outlet

tube volume, sample or reagent could enter the pump

and mix with liquid in the reservoir.

Loading...

Loading...