I-769N.Preaction/AC-ELEC / Victaulic

®

Series 769N FireLock NXT

™

/ Installation, Maintenance, and Testing Manual

REQUIRED AUTOCONVERT SYSTEM TEST

Victaulic recommends the AutoConvert system test every year (at

minimum).

1. Notify the authority having jurisdiction, remote station alarm

monitors, and those in the affected area that the AutoConvert

system test will be performed.

2. If a Series 746-LPA Dry Accelerator is installed, close the isolation

ball valve.

3. Open the water supply main drain valve fully to flush the water

supply of any contaminants.

4. Close the water supply main drain valve.

5. Close the water supply main control valve.

6. Open the system main drain valve slightly to lower the system air

pressure approximately 3 – 5 psi/21 – 34 kPa/0.2 – 0.3 Bar.

DO NOT drop the system air pressure below 10 psi/69 kPa/0.7 Bar.

6a. Verify that the AutoConvert air pressure gauge (item 11 on pages 8

and 9) maintains pressure and does not track system air loss.

6b. Remove power from the FACP.

6c. Verify that the latching solenoid of the AutoConvert system opens.

Air pressure decay on the system pressure gauge (item 6 on pages

8 and 9) should track with the AutoConvert air pressure gauge

(item 11 on pages 8 and 9).

6d. Restore power to the FACP.

7. Close the system main drain valve.

8. Close the slow-fill ball valve on the AMTA

9. Open the fast-fill ball valve on the AMTA. Bring the pressure back

up to the normal system pressure.

10. When normal system air pressure is reached, close the fast-fill ball

valve on the AMTA.

11. Open the slow-fill ball valve on the AMTA.

12. If a Series 746-LPA Dry Accelerator is installed, open the isolation

ball valve.

13. Open the water supply main drain valve.

14. Open the water supply main control valve slowly until water flows

steadily from the open water supply main drain valve.

15. Close the water supply main drain valve when a steady flow of

water occurs.

16. Open the water supply main control valve fully.

17. Confirm that all valves are in their normal operation positions (refer

to the table below).

Valve Normal Operating Position

Water Supply Main Control Valve Open

Water Supply Main Drain Valve Closed

System Main Drain Valve Closed

Charge Line Ball Valve of the Priming Manifold Assembly Open

Alarm Test Ball Valve of the Priming Manifold Assembly Closed

Slow-Fill Ball Valve of the Victaulic AMTA (if applicable) Open

Fast-Fill Ball Valve of the Victaulic AMTA (if applicable) Closed

Isolation Ball Valve for Series 746-LPA Dry Accelerator

(if applicable)

Open

¼-Turn Vent Ball Valve for Series 746-LPA Dry Accelerator

(if applicable)

Closed

18. Notify the authority having jurisdiction, remote station alarm

monitors, and those in the affected area that the valve is back in

service.

19. Provide test results to the authority having jurisdiction, if required.

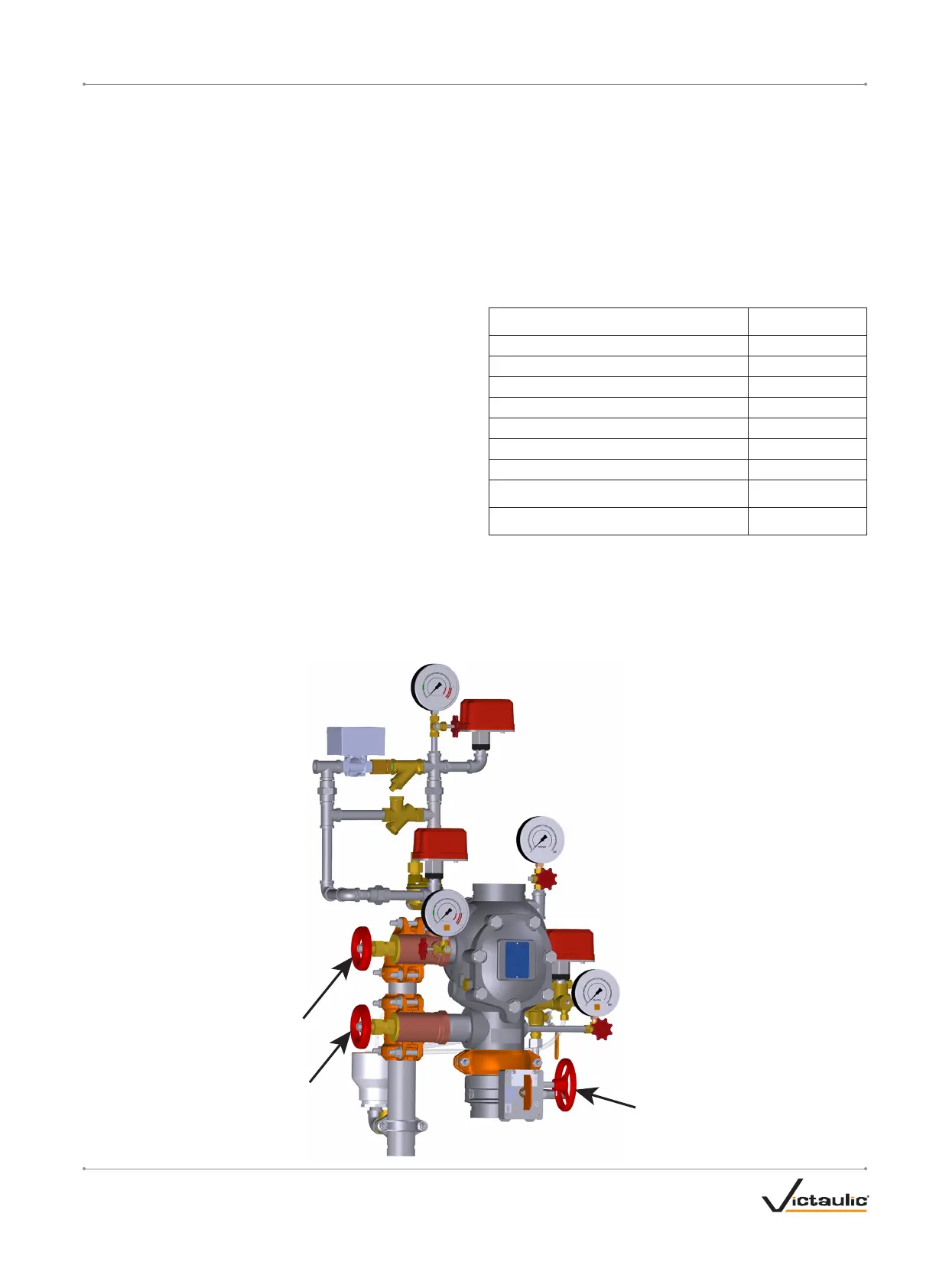

Water Supply

Main Drain Valve

(Steps 3, 4,

13, & 15)

Water Supply Main

Control Valve

(Steps 5, 14, & 16)

System Main

Drain Valve

(Steps 6 & 7)

I-769N.Preaction/AC-ELEC_23REV_A

Loading...

Loading...