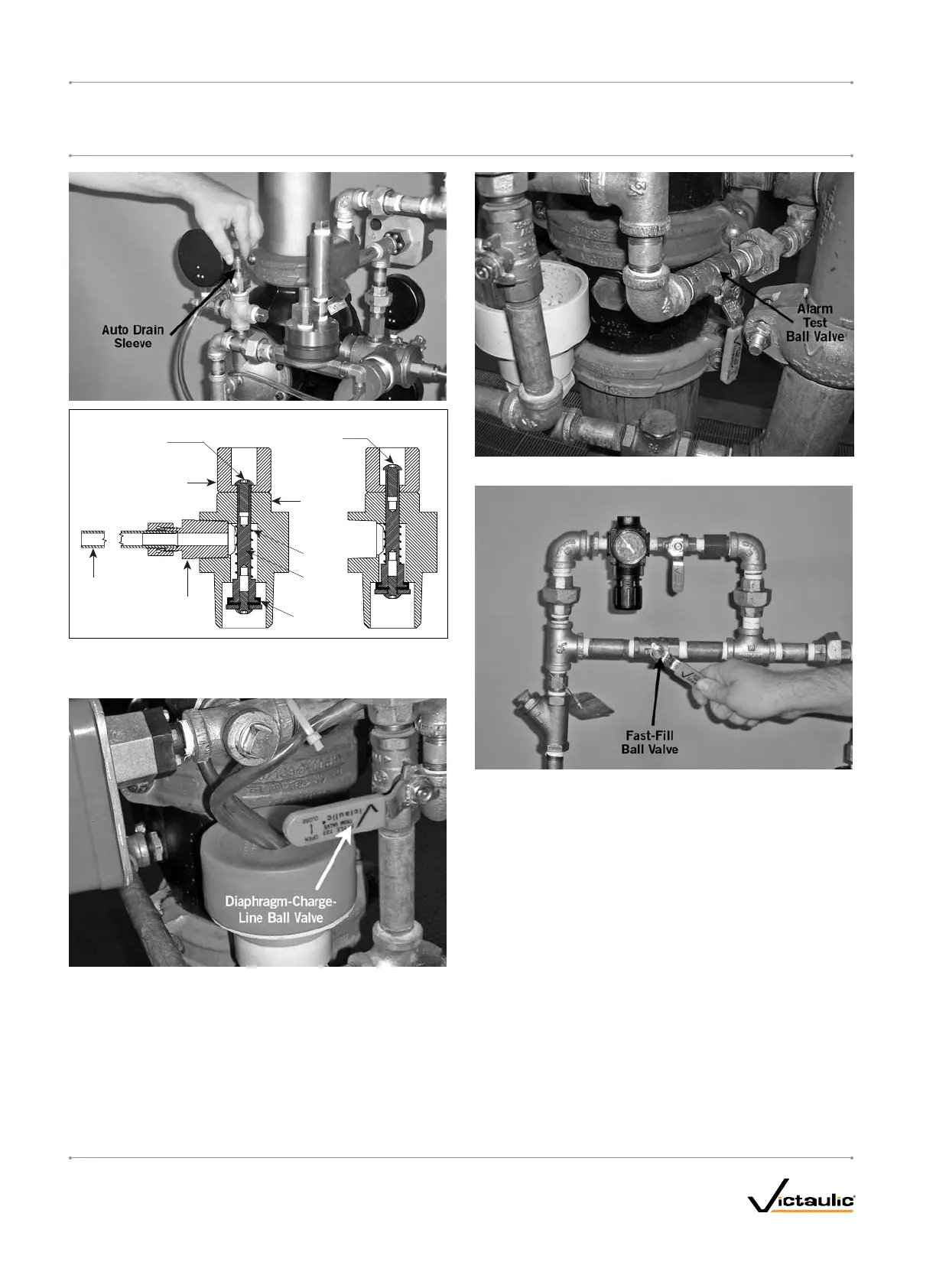

Screw

(Not in “set”

position)

Seal

Compression

Fitting

Drain

Hose

Body

Spring

Stem

Screw

(In “set”

position)

Sleeve

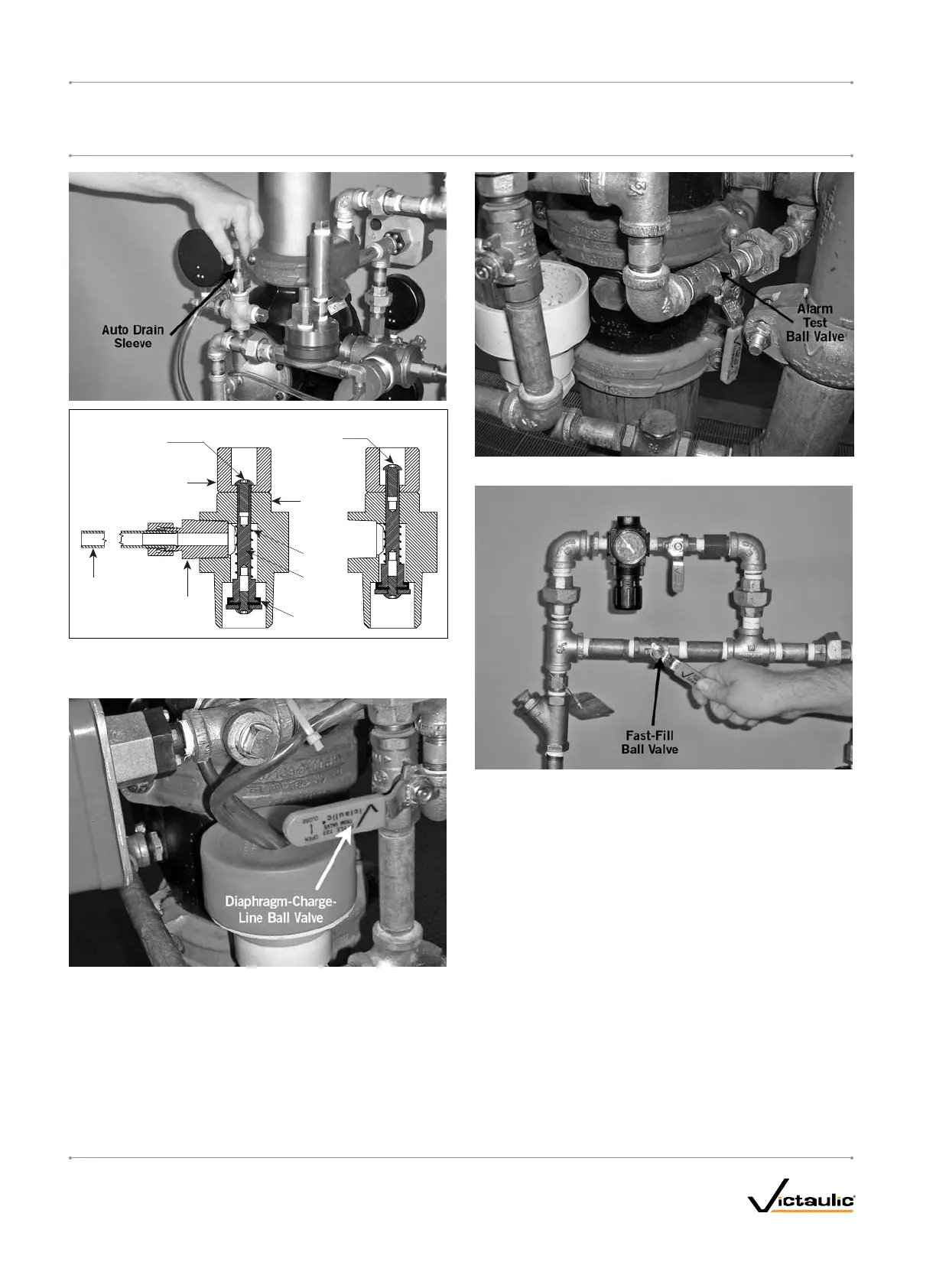

6. Confirm that water is flowing steadily from the Auto Drain. Pull up

on the Auto Drain Sleeve, and confirm that water is flowing through

the Series 776 Low-Pressure Actuator.

7. Close the diaphragm-charge-line ball valve.

8. Confirm that the alarm test ball valve is closed.

9. Charge the system with air by turning on the compressor or by

opening the fast-fill ball valve on the AMTA (fast-fill ball valve

is shown above). Charge the system to 13 psi/90 kPa/0.9 Bar

minimum. Refer to the “Air Supply Requirements” section.

9a. Confirm that the system is charging by observing the air

pressure gauge. If the gauge is not showing an increase in air

pressure, there is a leak or an opening in the line. Repair any

leaks or openings and restart the setup procedures.

10. Confirm that no water is being exhausted from the Auto Vent of

the Series 776 Low-Pressure Actuator. If water is being exhausted

from the Auto Vent, continue to run air through the system in

order to remove moisture from the upper chamber of the Series

776 Low-Pressure Actuator. If a Series 746-LPA Dry Accelerator is

installed, make sure the accelerator is not flooded.

I-768_14

FireLockNXT™DryValve

SERIES768

I-768

INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...