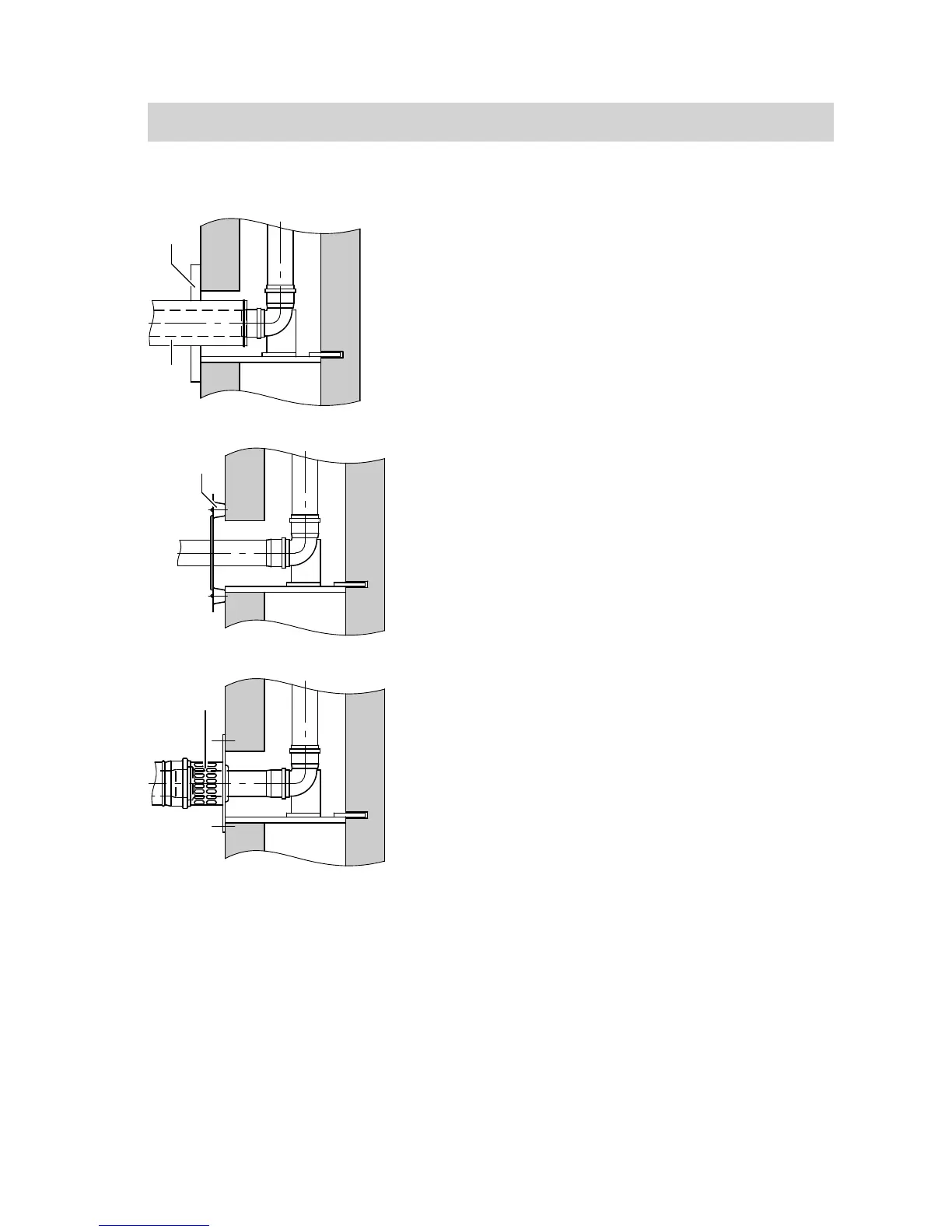

1. Only for balanced flue operation:

Trim final ventilation air pipe

L

of

the connection pipe so that it ends

level with the internal shaft wall sur-

face.

2. Balanced flue operation:

Slide balanced flue wall bezel

M

onto the pipe and push it against

the shaft opening.

Open flue operation:

Slide ventilation bezel

N

onto the

pipe and push it against the shaft

opening.

Note

The gap created provides secon-

dary ventilation to the shaft.

No additional ventilation grille is

required.

Open flue operation with combus-

tion air supply via interconnected

rooms:

Push the flue pipe onto the support

bend. Slide on air inlet adaptor

O

and secure it to the shaft.

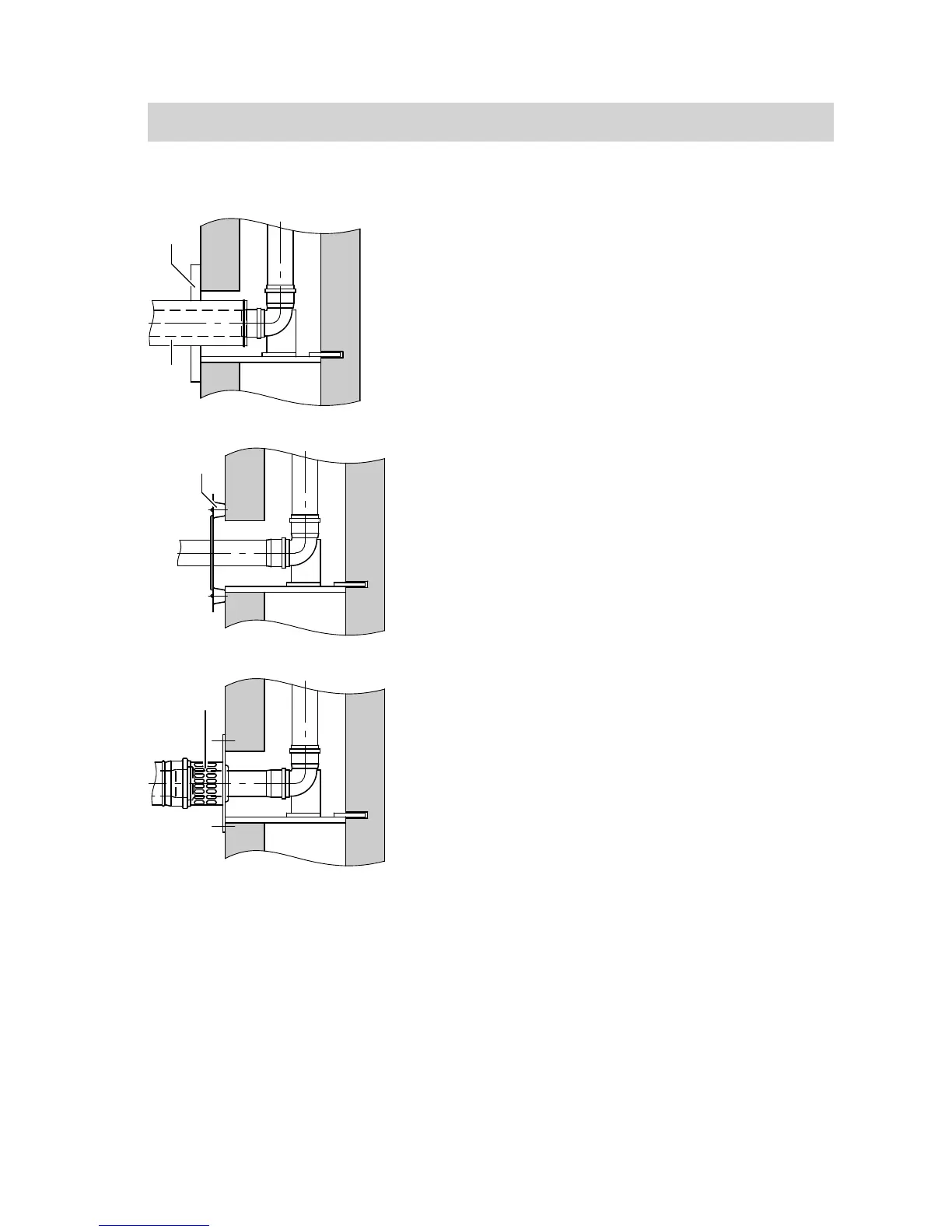

Fitting a metal shaft cover

For routing a plastic flue inside a twin

flue shaft, in conjunction with a solid

fuel boiler.

The metal end piece must protrude into

the shaft by a length that is equal to or

greater than the flue pipe diameter.

If necessary, use the stainless steel

extension which is available as an

accessory.

Routing through a shaft

(cont.)

5780 223 GB

Loading...

Loading...