Boiler Connections

30

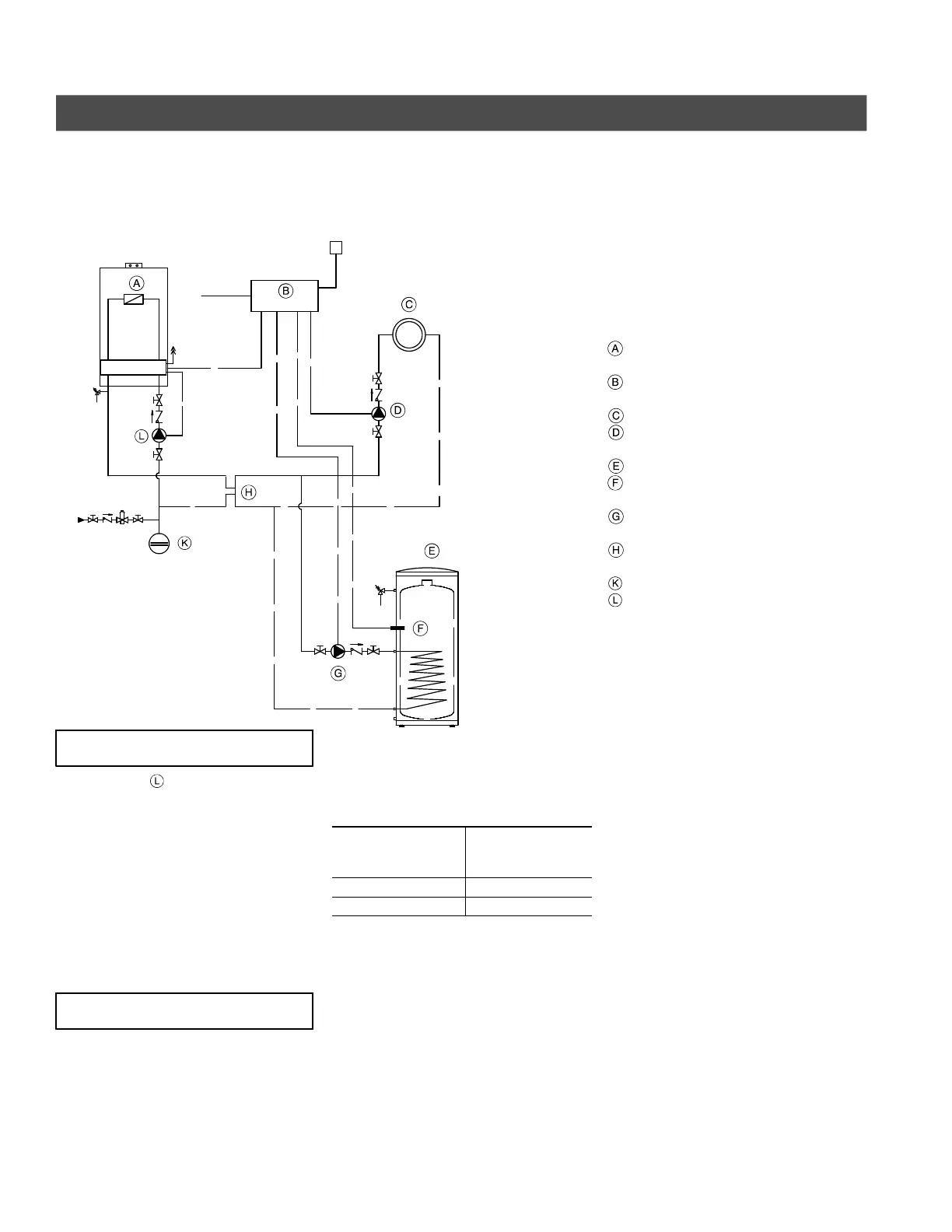

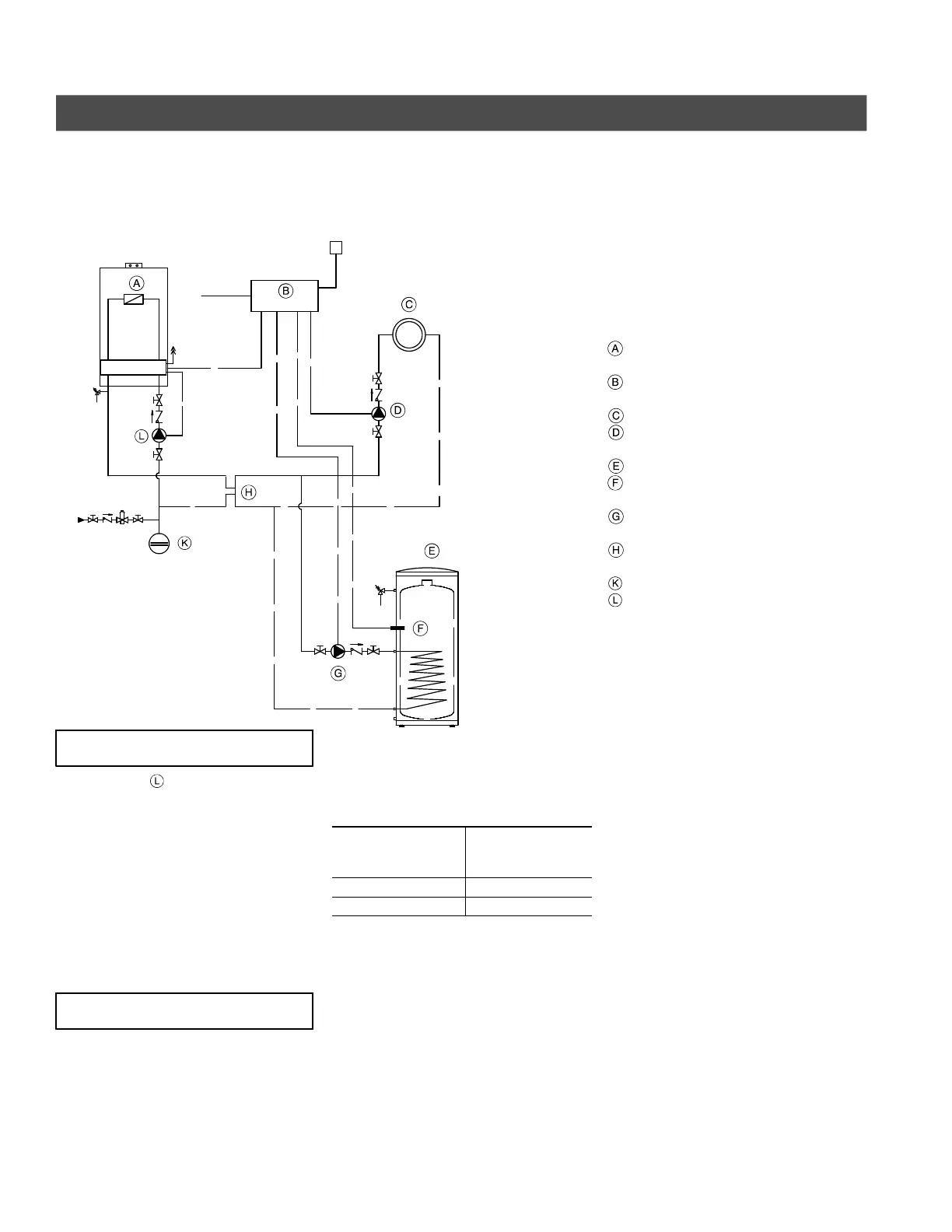

Installation Examples

(continued)

System Layout 3

Vitodens 100-W, WB1A 8-24, 8-30 with...

– DHW storage tank

– one heating circuit

Primary pump must pump into

the boiler (as illustrated).

AV Air vent

PRVPressure relief valve

TPVTemperature and pressure relief

valve

Vitodens 100-W gas-fired

condensing boiler

External boiler/DHW controller

(field supplied)

Heating circuit

Heating circuit pump

(field supplied)

DHW storage tank

DHW tank temperature aquastat or

sensor

DHW circulating pump

(field supplied)

Closely spaced tees, 4xpipe Ø

or 12” /305mm

*

Expansion tank

Primary pump (boiler circuit, field

supplied)

*

A low-loss header offers additional

benefits not provided by a pair of

closely spaced tees. Viessmann

strongly recommends and prefers the

use of a low-loss header over closely

spaced tees.

Please see page 36 for details.

Please note!

The use of a low-loss header is

recommended if the water flow rate is

less than 1.7 GPM / 400 ltr/h or more

than 6.2 GPM / 1400 ltr/h.

The low-loss header is available as

accessory part.

See page 36 in this manual for details

on the low-loss header.

Model No.

Vitodens 100-W,

Max. flow rate

(GPM/ltr/h)

WB1A 8-24 6.2/1400

WB1A 8-30 6.2/1400

DHW supply and return piping between boiler DHW connections and the Viessmann DHW tank connections, shall be a

minimum of 1” nominal pipe diameter (irrespective of the ¾” DHW connection outlet sizes provided on the boiler and the

DHW tank). This will ensure pump head is fully utilized to overcome the resistance of the DHW heat exchanger coil and to

provide sufficient water flow to the boiler heat exchanger.

In non-Viessmann DHW tank applications, perform, in addition to the above, accurate calculations for DHW tank coil

pressure drop versus boiler pump head to ensure sufficient water flow to the boiler heat exchanger. Failure to heed the

above instructions may cause boiler short-cycling and inadequate DHW supply.

5581 775 1.3

AV

PRV

TPV

Y

Y

4xpipe Ø

or 12” /305mm

IMPORTANT

IMPORTANT

Loading...

Loading...