Control Connections

38

Electrical Connections

(continued)

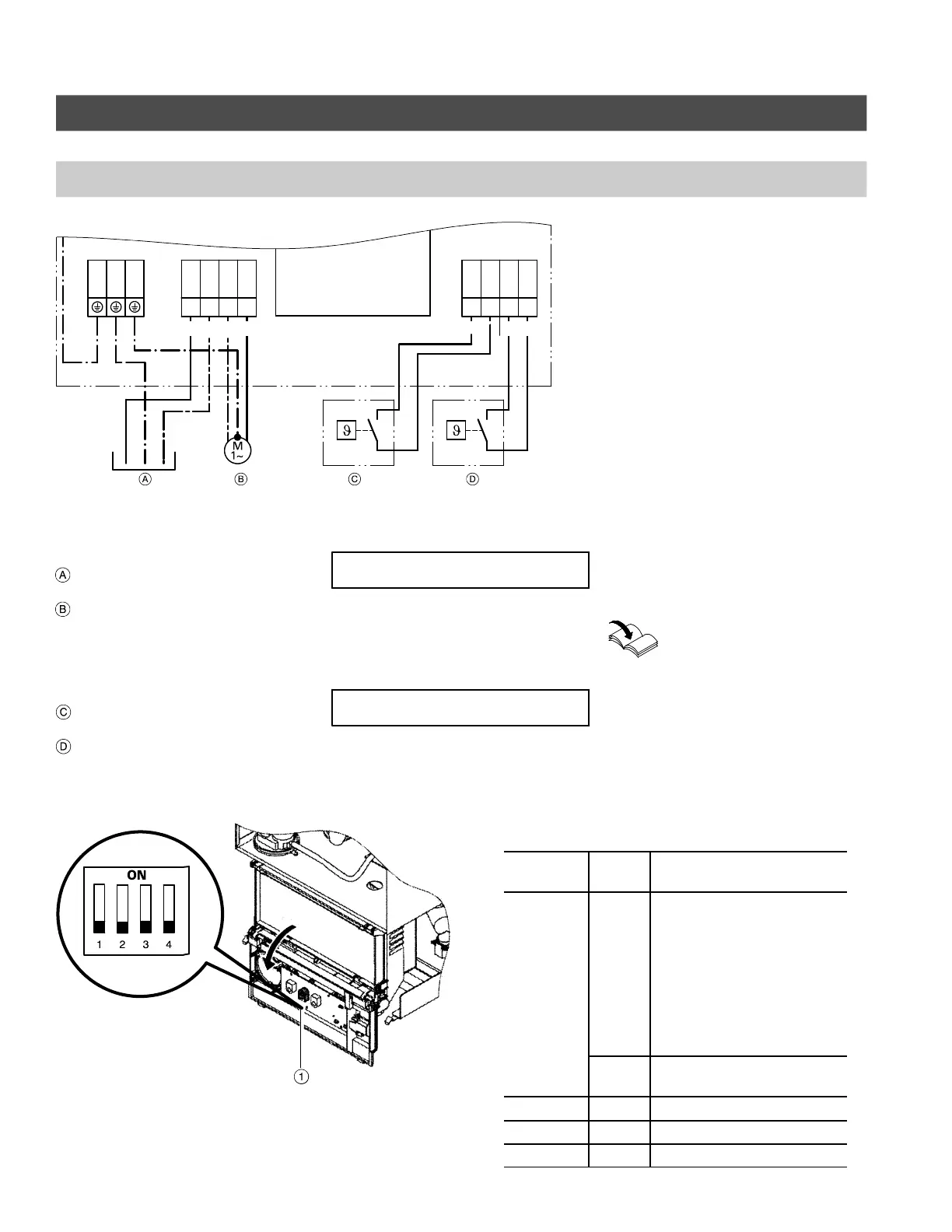

Electrical connections to the power pump module

X2 X4 1 2 3 4X3 L N N L

120V

PUMP

RT

Note:

Boilers are factory shipped with

a wiring diagram (11”x17” page

inside a pouch) attached to the

inside of the front cover. The

wiring diagram shipped with the

boiler supercedes the wiring in-

formation in this manual.

Provide main power disconnect/service switch as per local code

requirements. Also refer to wiring diagram on page 71.

DHW

Legend

Main power supply

(120V, 60Hz, 1 PH).

Heating circuit pump (or boiler

pump with low-loss header

application). See DIP switch

selection setting S1 below. (Pump

runs for 10 seconds every 24

hours).

DHW tank temperature controller /

external heat demand

Room temperature thermostat

(Anticipator setting 0.2A)

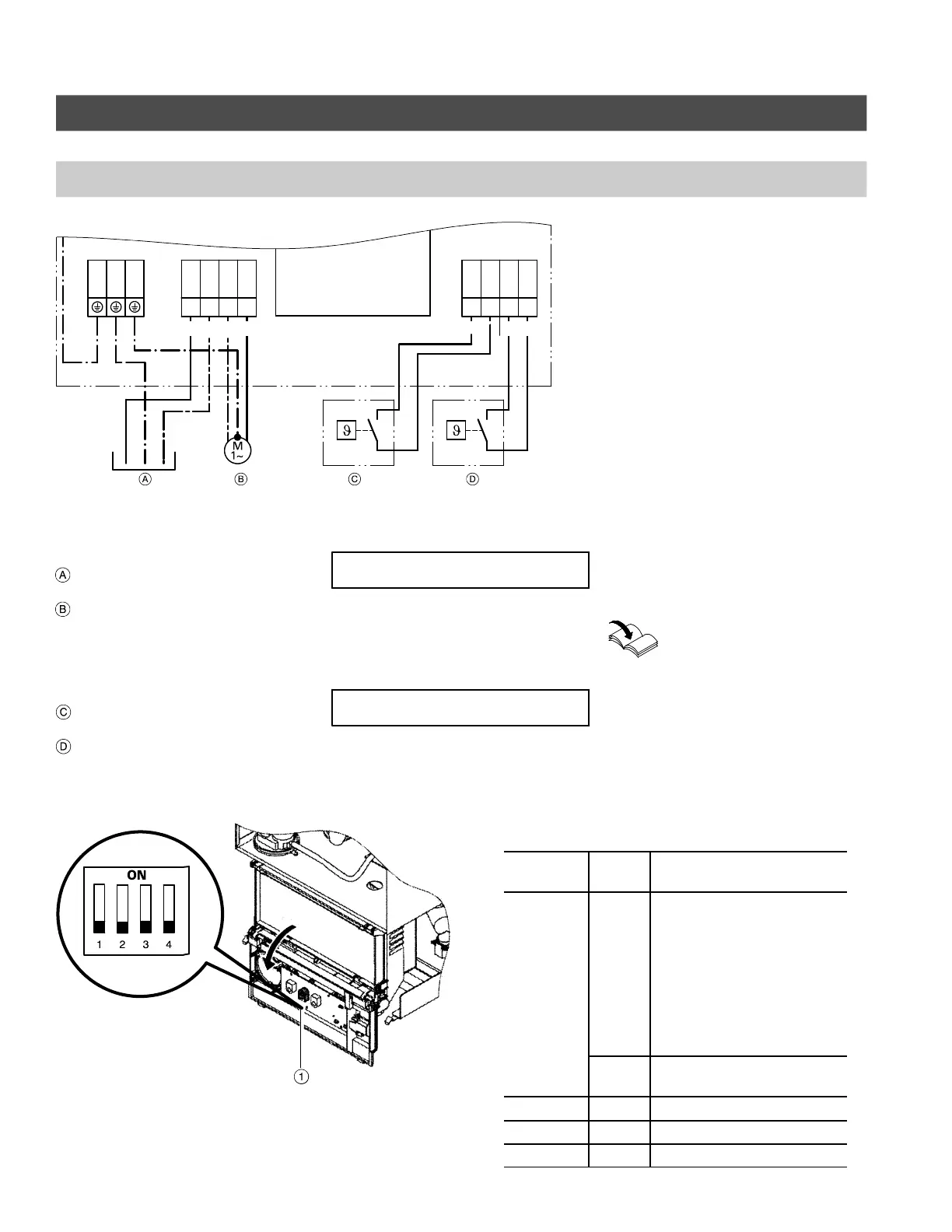

DIP switch settings - S1

Remove short factory test leads from

terminal L, N and Ground before

connecting main power supply to

boiler.

Ensure that pressure activated by-pass

is installed with system layout 1 on

page 28.

Note:

If the boiler is operated using a 10VDC

modulating signal...

See separate OpenTherm (OT)

Module Installation

Instructions.

DIP switch settings - S1

Dip switch

number

Setting Explanation

1 OFF Pump B is ON during call

for heat. After call for heat

(RT-Terminal) is satisfied

pump B post-purges for

12 mins.

After DHW/external heat

demand (ST-Terminal) is

satisfied, pump B post-

purges for 1.5 minutes (see

important note above).

ON Pump B operates continu-

ously

2 OFF Do not adjust

3 OFF Do not adjust

4 OFF Do not adjust

5581 775 1.3

S1

Factory default settings

for S1 DIP switch

1 Dip switch S1

IMPORTANT

IMPORTANT

Loading...

Loading...