Troubleshooting

64

Diagnosis

(continued)

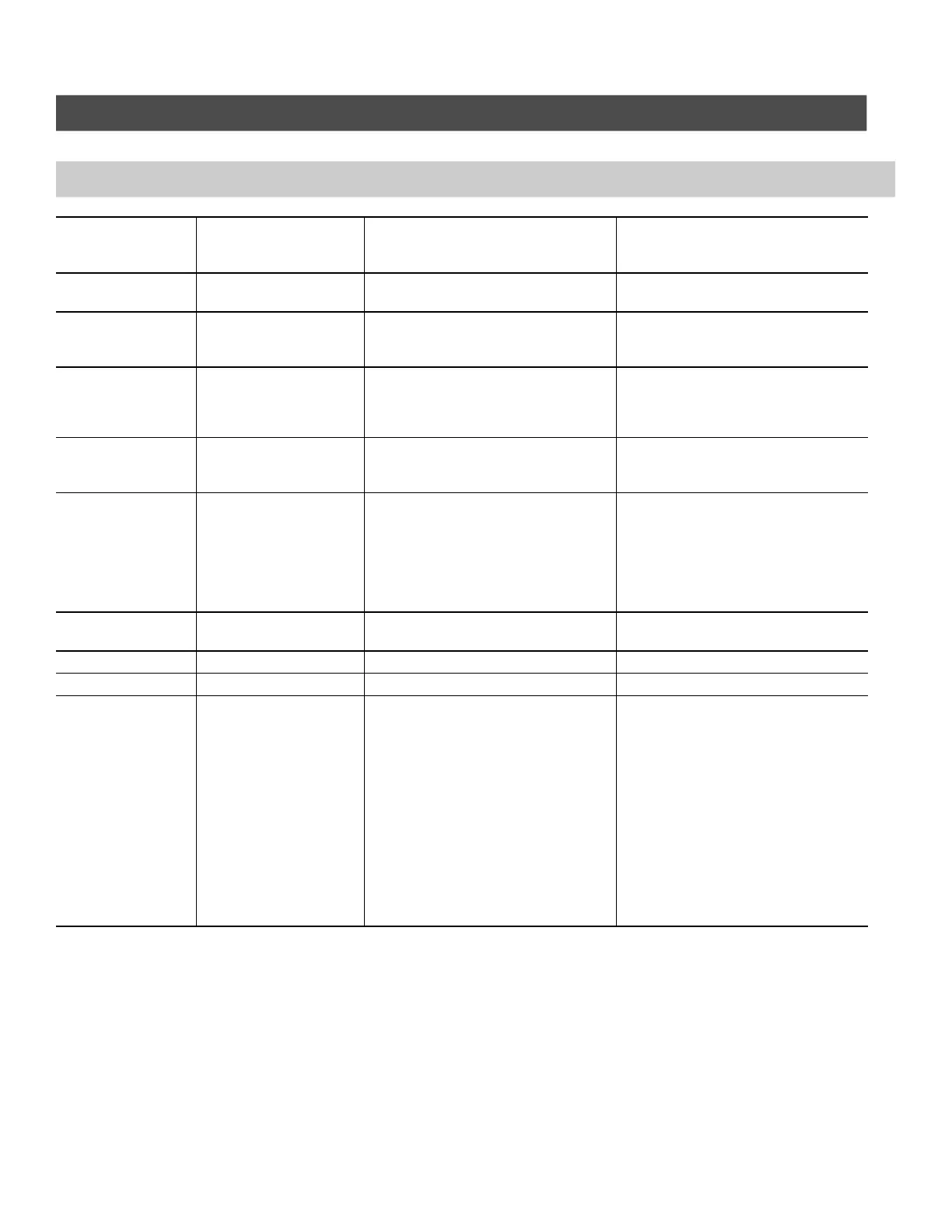

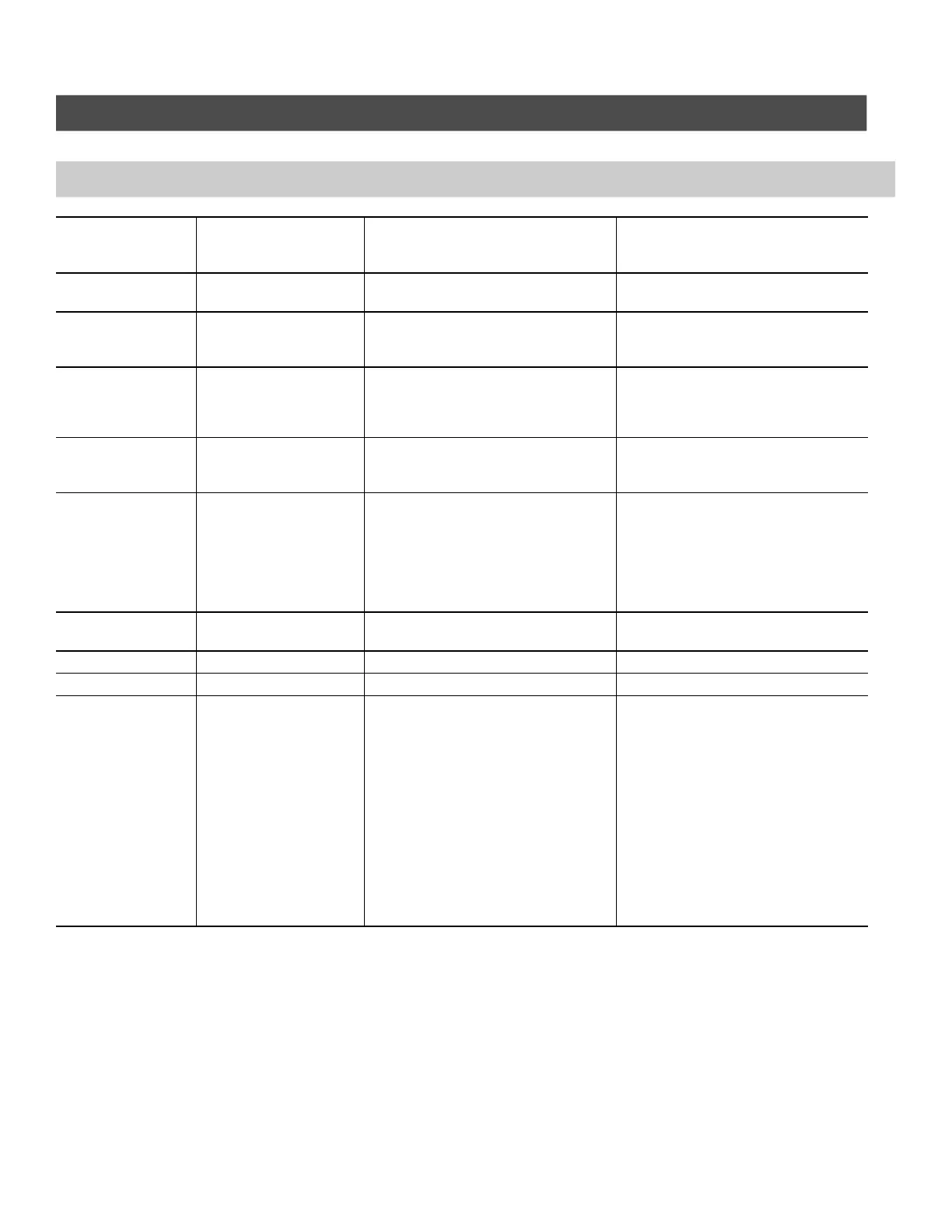

Diagnostics table: Faults with fault display on control unit (continued)

Fault mes-

sage in dis-

play window

System behavior Cause Corrective measures

f7

Burner blocked Faulty water pressure sensor Check the water pressure sensor and

the interconnecting cable.

f8

Burner in fault mode Combination gas valve closes too

late

Check the gas combination valve.

Check both air and gas paths.

Press “Reset”.

f9

Burner in fault mode Blower speed too low at burner start Check the blower, check the blower

cables and supply, check the blower

control.

Press “Reset”.

fa

Burner in fault mode Blower not at stand-still (blower

must be in stand-still when in stand-

by mode)

Check the blower, check the blower

cables, check the blower control.

Press “Reset”.

fd

Burner blocked Burner control unit fault Check the ignition electrodes and

leads. Check whether a strong inter-

ference (EMC) field exists near the

equipment.

Press “reset”.

If the fault is not removed, replace

the control unit.

fe

Burner blocked Faulty main PCB If the equipment will not restart after

resetting, replace control unit

18

Burner in fault mode DIP switch S2 is set to “ON” Set DIP switch S2 back to “OFF”

58

Burner in fault mode DIP switch S4 is set to “ON” Set DIP switch S4 back to “OFF”

a9

Non-permanent lock-out

(burner in fault mode)

Communication error OpenTherm

Module

Turn boiler OFF, then ON

Check communication cable on Ter-

minals X3.3, X3.4 on boiler controls.

Check connection on OT-Module sub

base Terminals 12, 13.

Check 24VAC output of PPM of the

boiler Terminals X4.3, X4.4 (RT Ter-

minals).

Check for 0-10VDC input signal (a

min. of 3.0 volts is required to start

up the boiler).

5581 775 1.35581 775 1.3

Loading...

Loading...