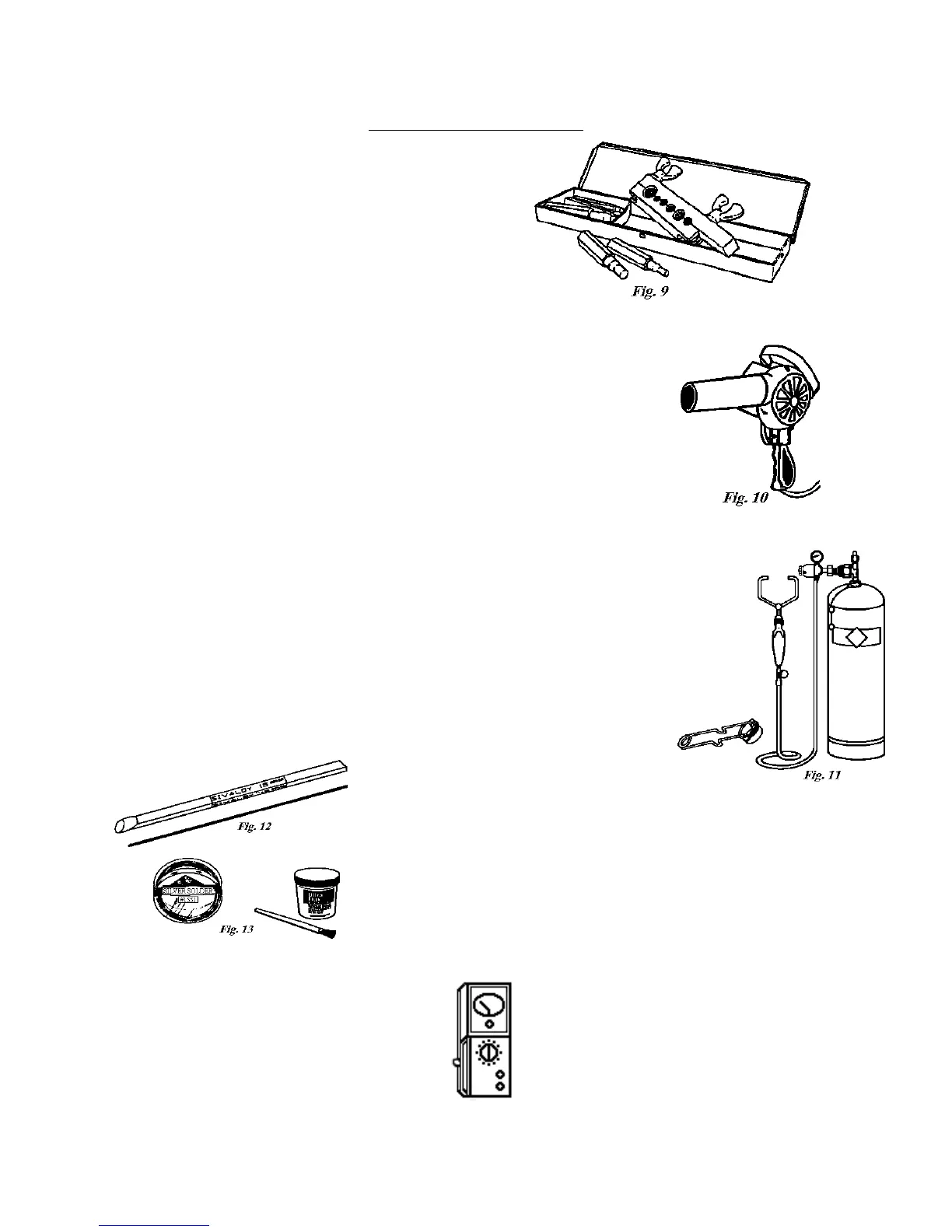

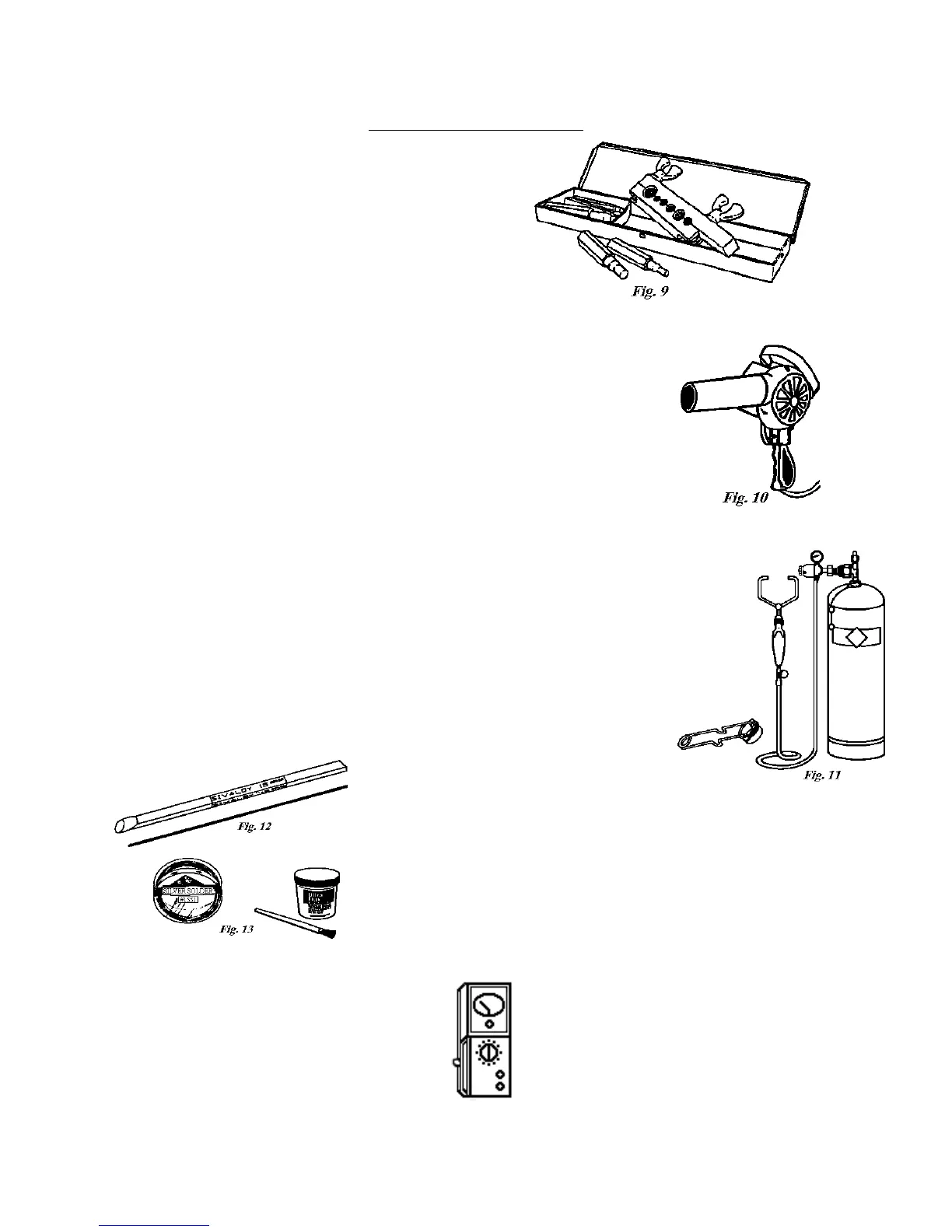

EQUIPMENT DESCRIPTION

Swaging Kit – A swaging tool kit may be needed to

expand system tubing to fit replacement parts. (Fig. 19)

Heat Gun – A heat gun can be used to heat a non-operating compressor or the

evaporator during purge and the refrigerant tank to increase charging pressure.

Many heat guns have a stand that allows continuous operation while other

repairs are made. A heat gun rated at 1500 watts or greater is recommended.

(Fig. 10)

Single MC-Size Fuel Tank of Acetylene with a Double Tip Torch – The

MC-size single fuel tank of acetylene gas is very portable and easy to use. Two

torches are acceptable for use: A double-tip torch heats both sides of the joint

at the same time and is less likely to scorch the inside of the tubing; A single-

tip Turbo-brand torch equipped with a flame reflector will also heat both sides

of a joint and provide a hotter flame. A striker is used to light the torch.

(Fig.11)

15% Silver Brazing Alloy (Silfos) – Silfos can be used for all

copper to copper sealed system brazing. (Fig. 12) A 45 % silver

solder and flux must be used to braze copper to steel. (Fig. 13)

Frequency Meter

15

Loading...

Loading...