VWR Rotary Vane Pump ver 1.3 23.11.2020

4.0 Installation

4.10 Pump Location

WARNING!

Don’t operate this pump in an atmosphere containing flammable or explosive gas.

The pump should be located in a clean and well-ventilated area and adequate space should be provided

wherever possible for routine maintenance such as oil changes. For best performance, the pump should be

located as closely as possible to its system. Determining factors for pump location should include length and

size of connections, the number of bends, and the type of exhaust connections.

4.20 Pump Mounting

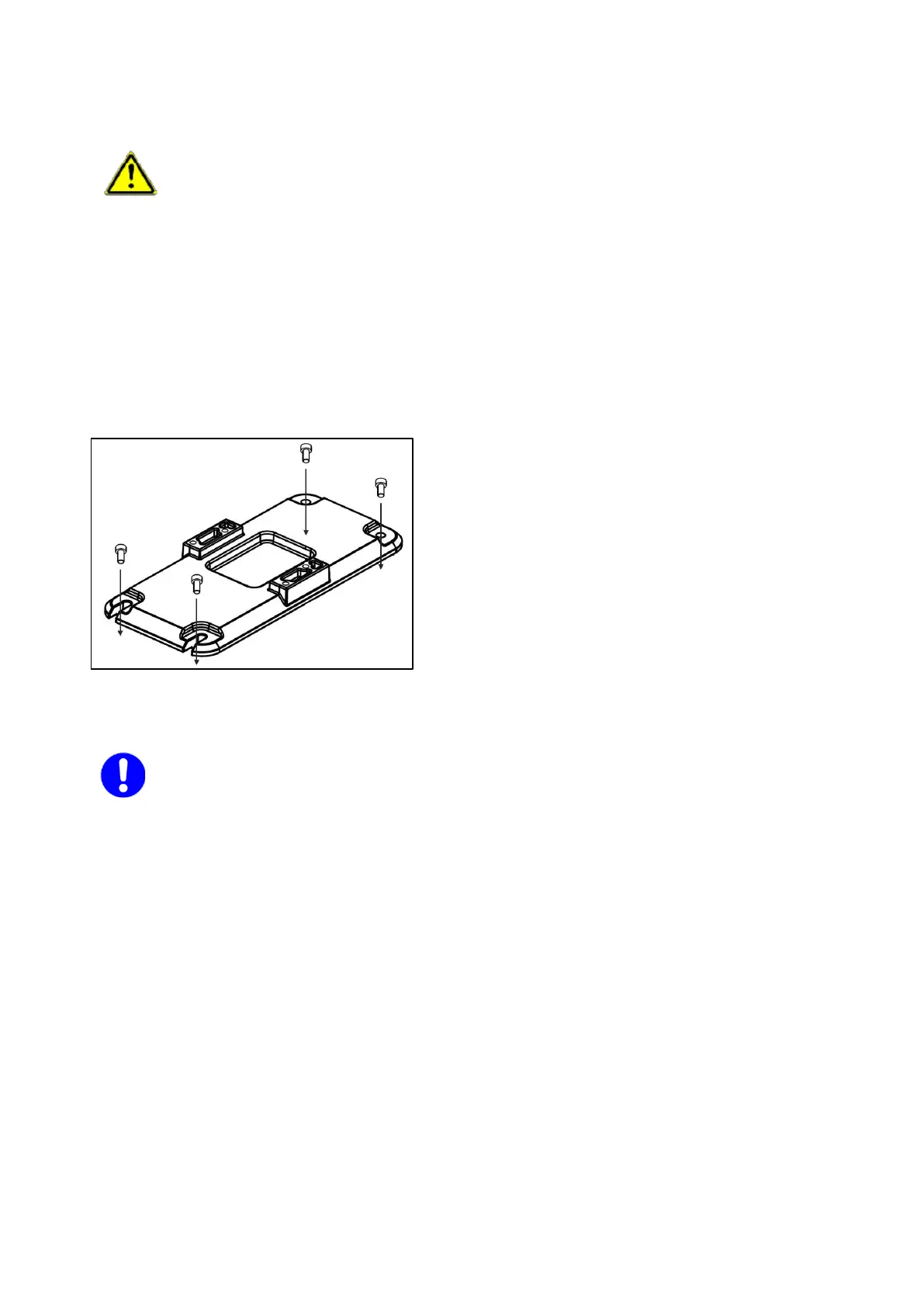

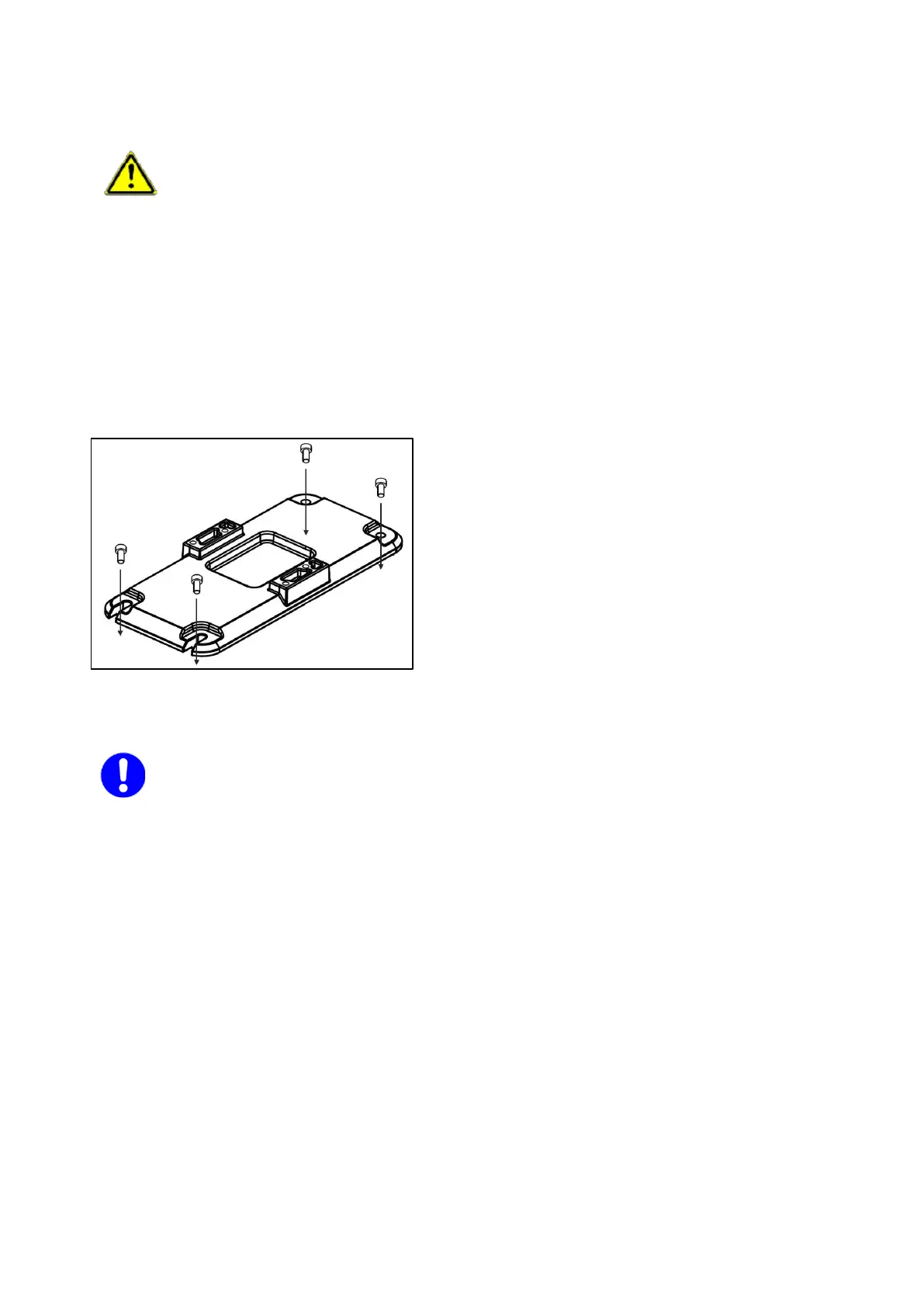

For more rigid mounting requirements the pump base can be bolted directly to a surface using the 2

mounting holes and 2 slots featured on the base.

Fig. 1: Pump mounting

4.30 General References

CAUTION!

On continuous operation it’s recommended to run the pump below 10 mbar maximum

vacuum pressure.

According to its intended use the capacity of the vacuum pump depends on:

- the kind of assembly

- accessories

- the oil used

- additional connections

- vacuum piping system

In addition, fail-safe operation is determined by the mode of maintenance. Elements such as valves, filters,

condensers a.s.o. should be provided as early as in the conception. The materials of the vacuum piping

should be selected in such a way that they will be resistant to the media to be delivered!

- Regularly check and clean the air inlet of the motor ventilator.

- The structural elements used on the inlet and outlet sides must be resistant to the media to the

pumped. The pressure on the outlet side must not exceed 1 bar!

- A pressure that is slightly below the air pressure helps to avoid pollution of gases, and reduces

corrosion.

Loading...

Loading...