VWR Rotary Vane Pump ver 1.3 23.11.2020

8.30 Function

8.31 Working Principle

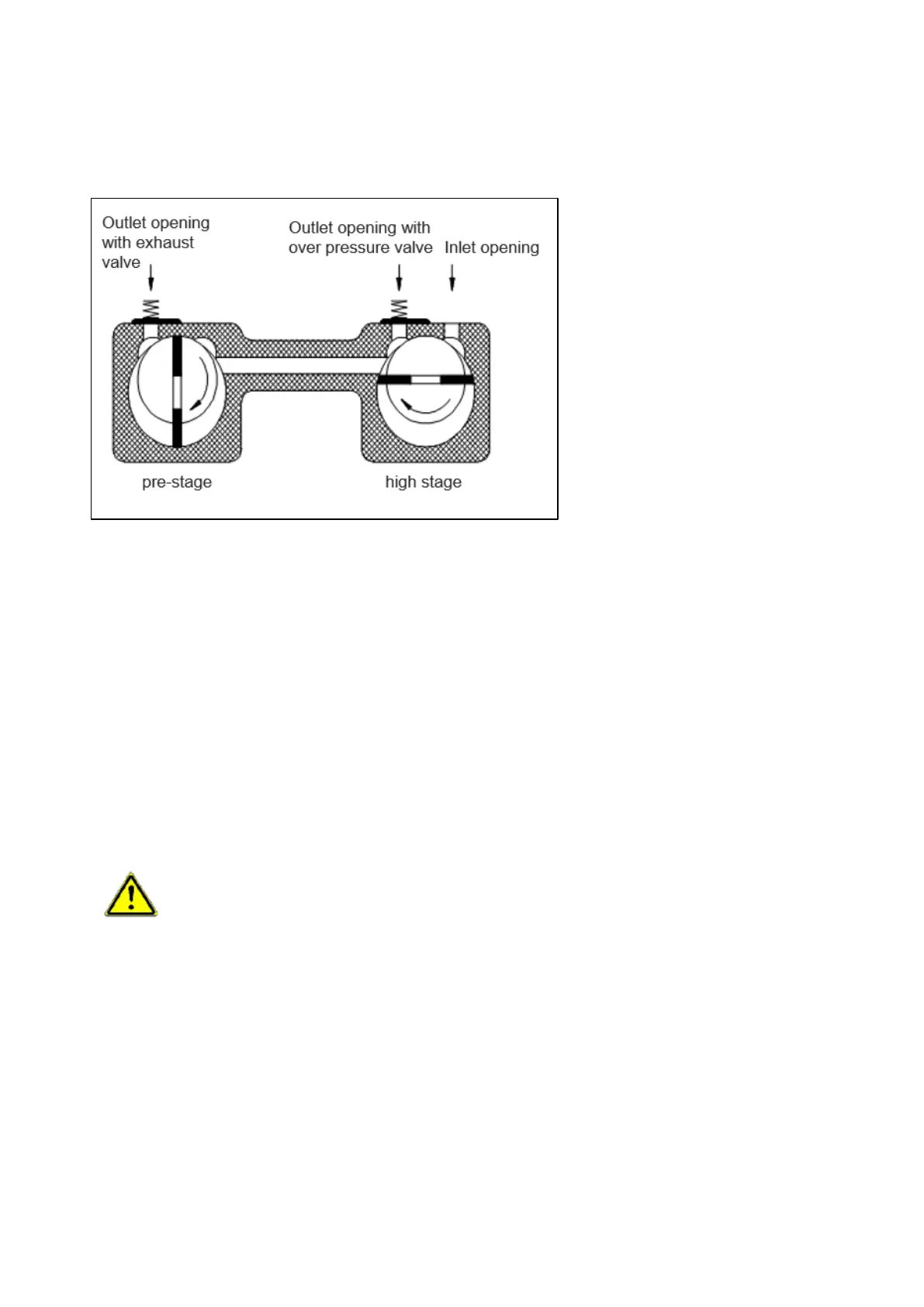

Two pump stages (fore-stage and high-stage) are arranged in series in order to improve the end pressure

and the pumping speed at lower pressures. The intake takes place in the first stage (high-stage), the

compression and the outlet in the second stage (fore-stage).

Fig. 8: Pre-stage / high-stage

The pump body is subdivided into several chambers by the eccentrically arranged rotor which has two

radically sliding vanes. The volume of each chamber changes cyclically as the rotor turns. This sucks the

gas into the intake opening. The gas flows through the dirt filter, which is connected to the centring ring, into

the pump body. After the intake opening is closed by the vane, the gas is transported onwards and

compressed.

A dosed quantity of air (gas ballast) can be let into the pump body during the compression by opening the

gas ballast valve. This prevents vapours condensing in the vacuum pump. Oil is injected into the pump body

for sealing and lubrication. An oil pump pumps oil out of the oil reservoir into a pressure oil lubrication

system that feeds all the bearings. The low-mounted oil suction pipe achieves a large usable oil reserve.

At the outlet valve, the compressed gas is pumped out of the pump body through the exhaust port. The oil

carried along with the gas is separated out by a filter (accessory).

8.32 Gas ballast

WARNING!

Condensable vapours may only be extracted when the gas ballast valve is open, when

the vacuum pump is at operating temperature and within the limits of the maximum

tolerance of water vapour pressure! Condensation occurs if the maximum water vapour

pressure tolerance is exceeded.

When pumping condensable vapours, they may be compressed during the compression phase above the

saturated vapour pressure and condense.

This causes considerable deterioration in the vacuum pump’s performance:

- ultimate pressure is not achieved

- corrosion occurs

- heavy oil contamination and formation of emulsions

When the gas ballast valve opens (to the left) air flows into the compression space. The air flowing in keeps

the partial pressure of the condensable medium so low that the pressure needed to open the outlet valve is

reached before the medium condenses.

Loading...

Loading...