VWR Rotary Vane Pump ver 1.3 23.11.2020

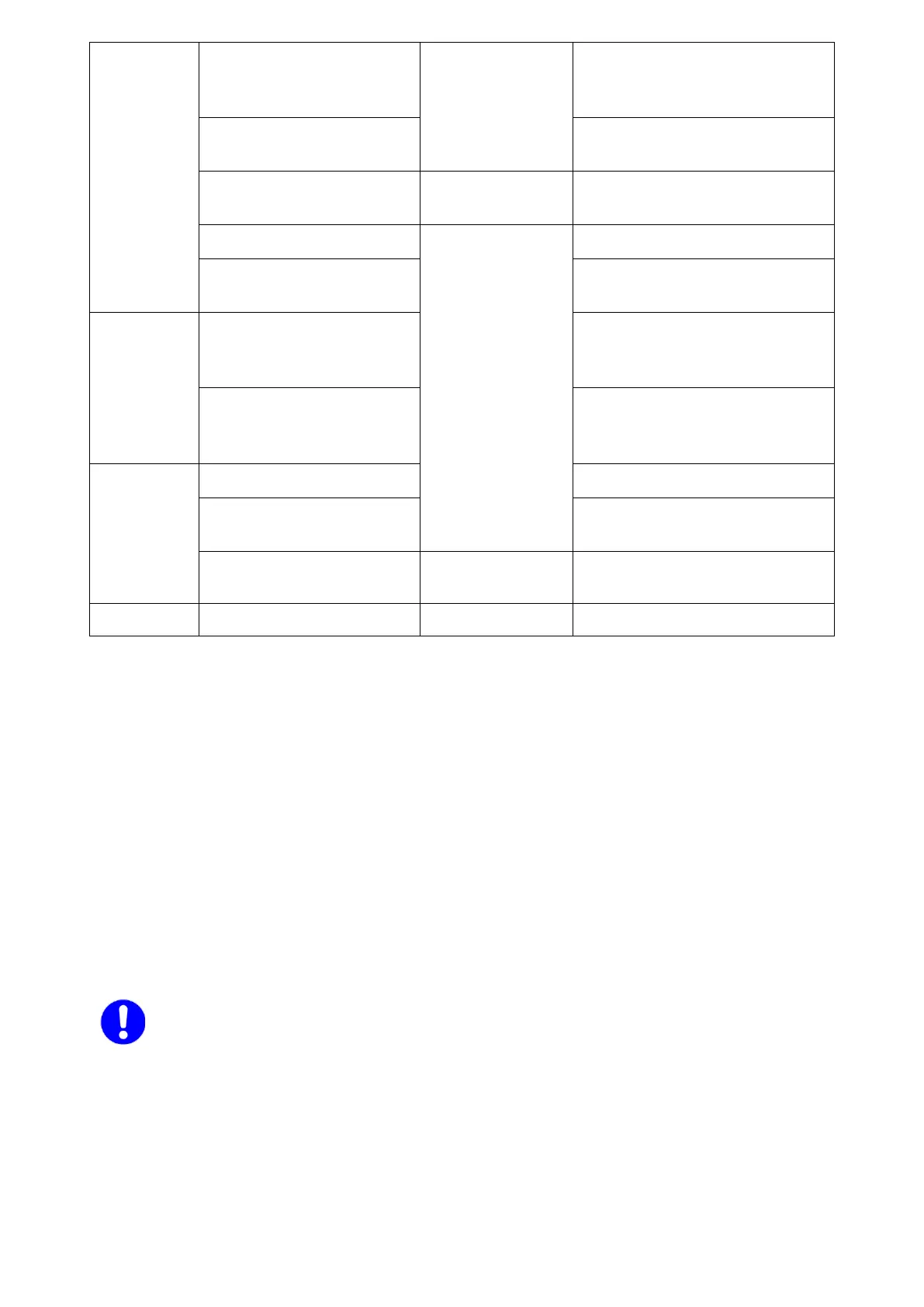

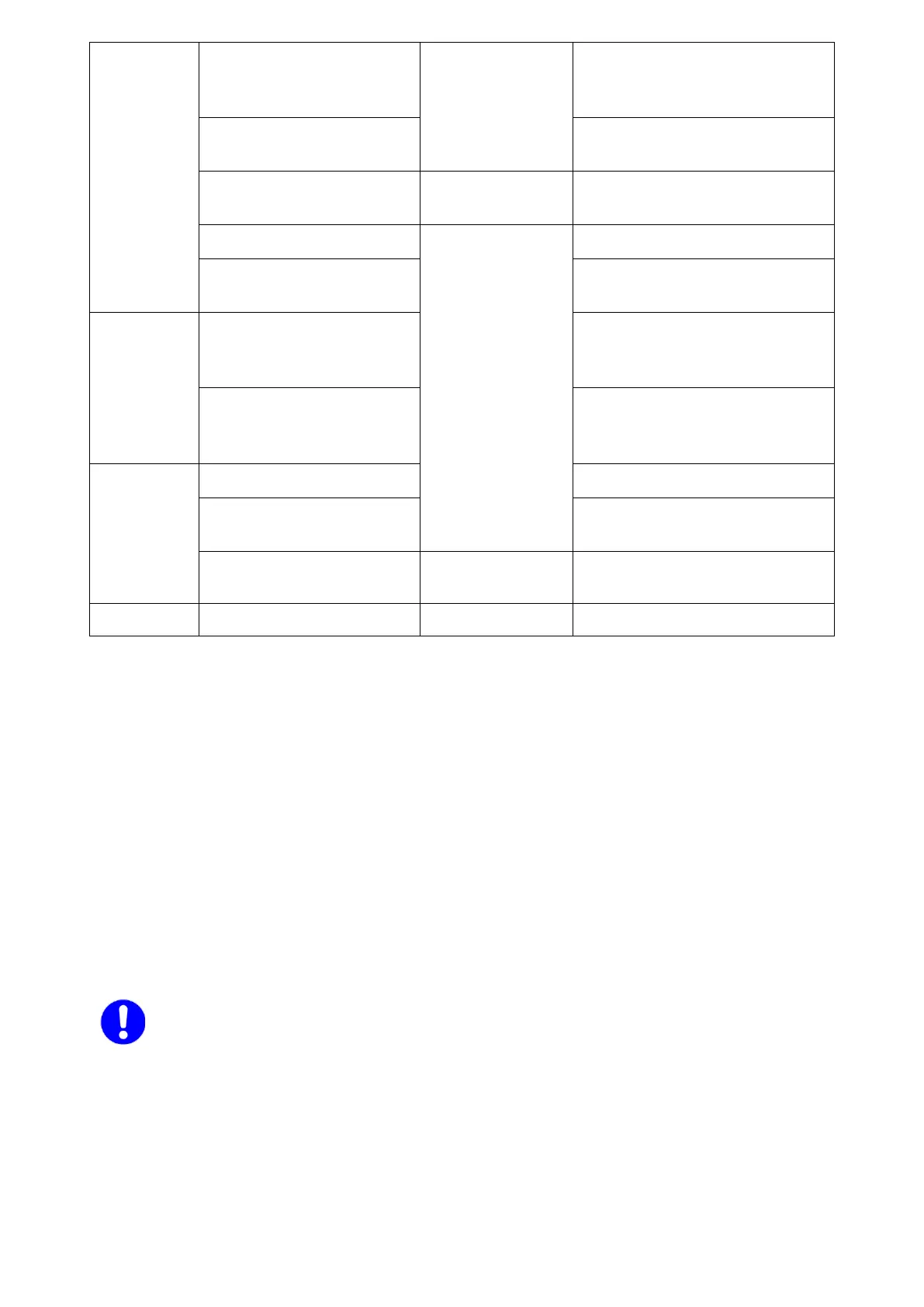

at operating temperature, 1 – 1.2 bar

overpressure, check that the pipes

are clear and have no leaks

Oil with too low a viscosity

used

Ambient temperature round

vacuum pump too high

Built-up pressure in the oil

casing too high (> 0.5 bar)

Check exhaust pipe change filter

insert

Through oil mist emission:

work or pressure control valve

defective

Because of leak from oil

casing: shaft seal defective, oil

casing seals defective

Vacuum pump

is not vacuum-

tight when

switched off -

possible rise in

oil pressure

Shaft seal ring on the drive

side or oil pump defective

Close the gas ballast valve

11.0 Repair and maintenance

11.10 Maintenance Performed by the User

Under normal operating conditions the maintenance of the rotary vane pump is limited to:

- external cleaning

- checking running noises

- checking the level and quality of the oil

- regular oil changes

These maintenance intervals must be specified according to the prevailing operating conditions and adhered

to. We recommend performing maintenance after every 1.000 hours. The bearings of the drive motors are

life-long lubricated and so maintenance-free.

CAUTION!

Only perform the work that is described here, and that which is permitted to be done

by the user. All other maintenance and service work may only be performed by the

manufacturer or a dealer authorized by him. Beware of the pump parts being possibly

contaminated by hazardous substances. Wear protective clothing if there is

contamination.

Loading...

Loading...