VWR Rotary Vane Pump ver 1.3 23.11.2020

11.20 Oil Level Control

CAUTION!

Check the oil level regularly!

The oil consumption varies according to the vacuum pump's operating conditions. In order to keep the

vacuum pump at all times in an optimum operating condition, the oil level must be inspected at the oil sight

glass. The oil level must at all times be showing between the upper and lower markings on the oil sight

glass. The oil must be topped up if the oil level falls to the lower mark. We recommend to operate pump with

oil filling at upper marking FULL. This minimize the service needs and allows better dilution of contaminants.

When additional oil is required, use only VWR RV+ Oil, pump performance is not guaranteed with other

brands of oil.

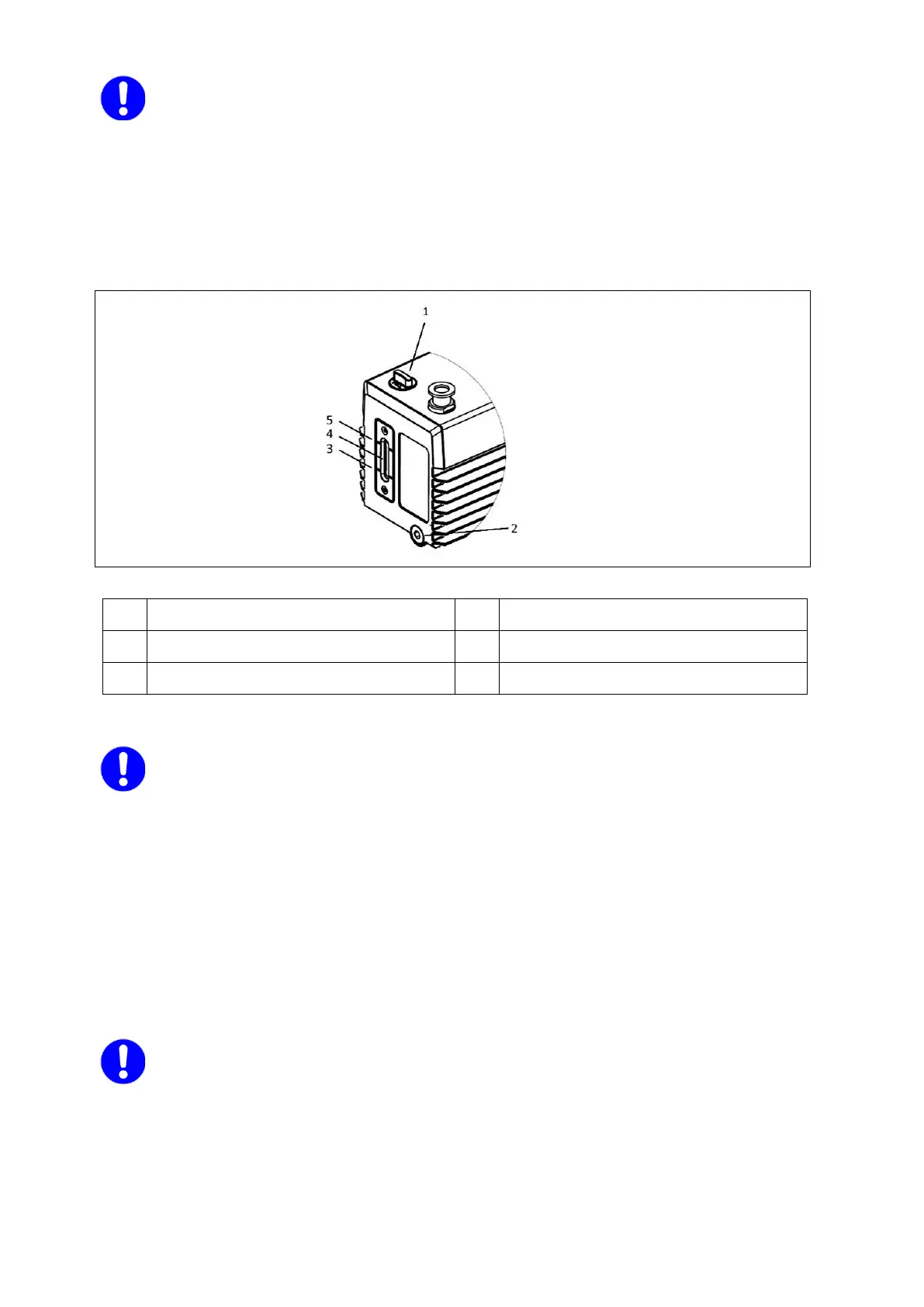

Fig. 9: Oil level control

CAUTION!

The condition and quality of the pump oil have a substantial effect upon the

performance and operational readiness of the vacuum pump!

Comparing the colour of a sample of the pump oil with fresh oil provides an indication of the contamination

of the pump oil. You obtain the oil needed for testing from the oil drain aperture with the vacuum pump

switched off and at operating temperature. If the oil appears slightly cloudy, e.g. because of water droplets, it

can be regenerated with the aid of the gas ballast, 9.50 Operation with gas ballast when drawing off

condensable vapours.

Brown or black oil or oil smelling as if it has burnt must be removed from the vacuum pump. Flush the

vacuum pump and fill up with fresh oil.

11.40 Oil Change

CAUTION!

If the vacuum pump has been used to pump media which are dangerous to health

then all measures must be taken to protect the service and operating personnel!

Loading...

Loading...