1

2

3

4

EN

9

GRAVITY FEED NOZZLE MATERIAL PREPARATION AND SETUP

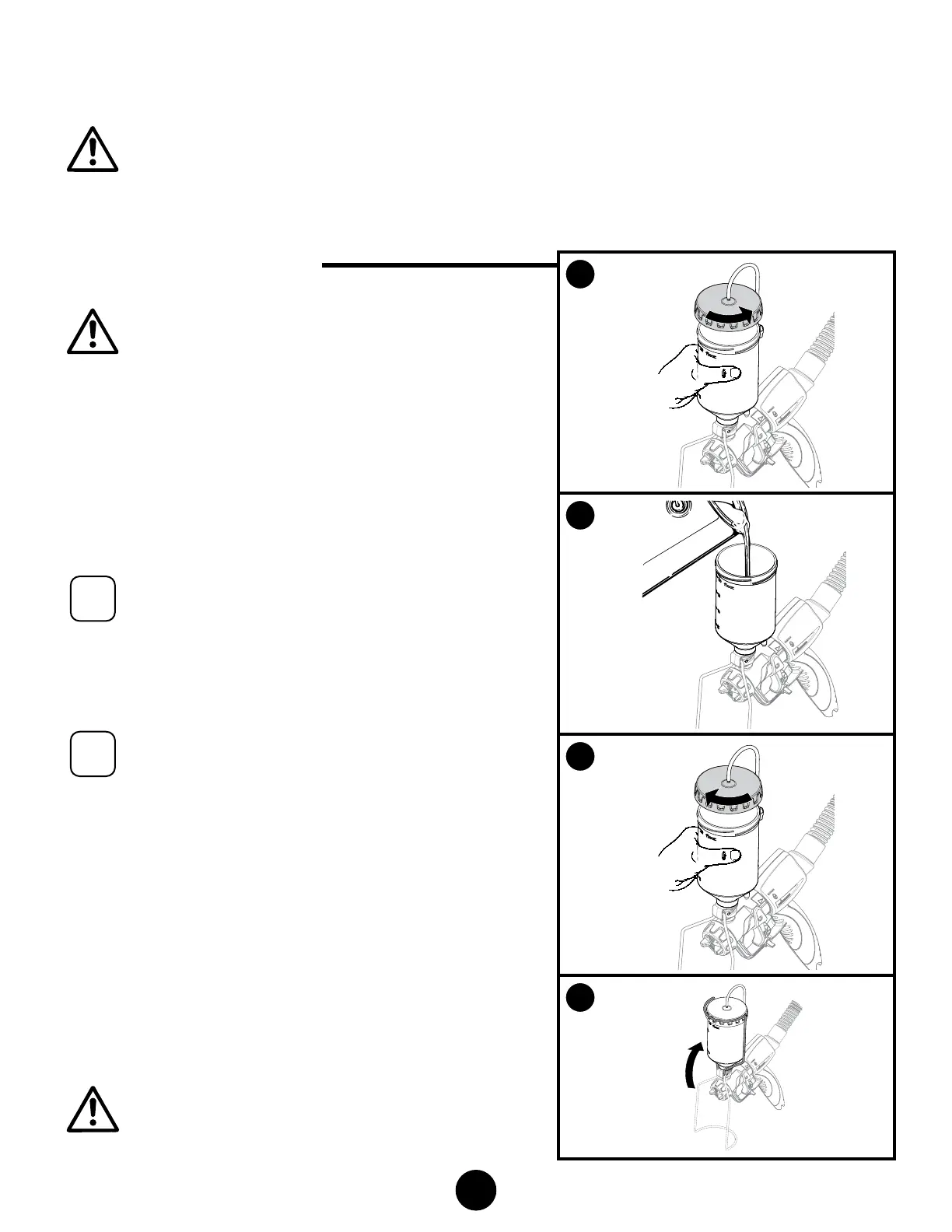

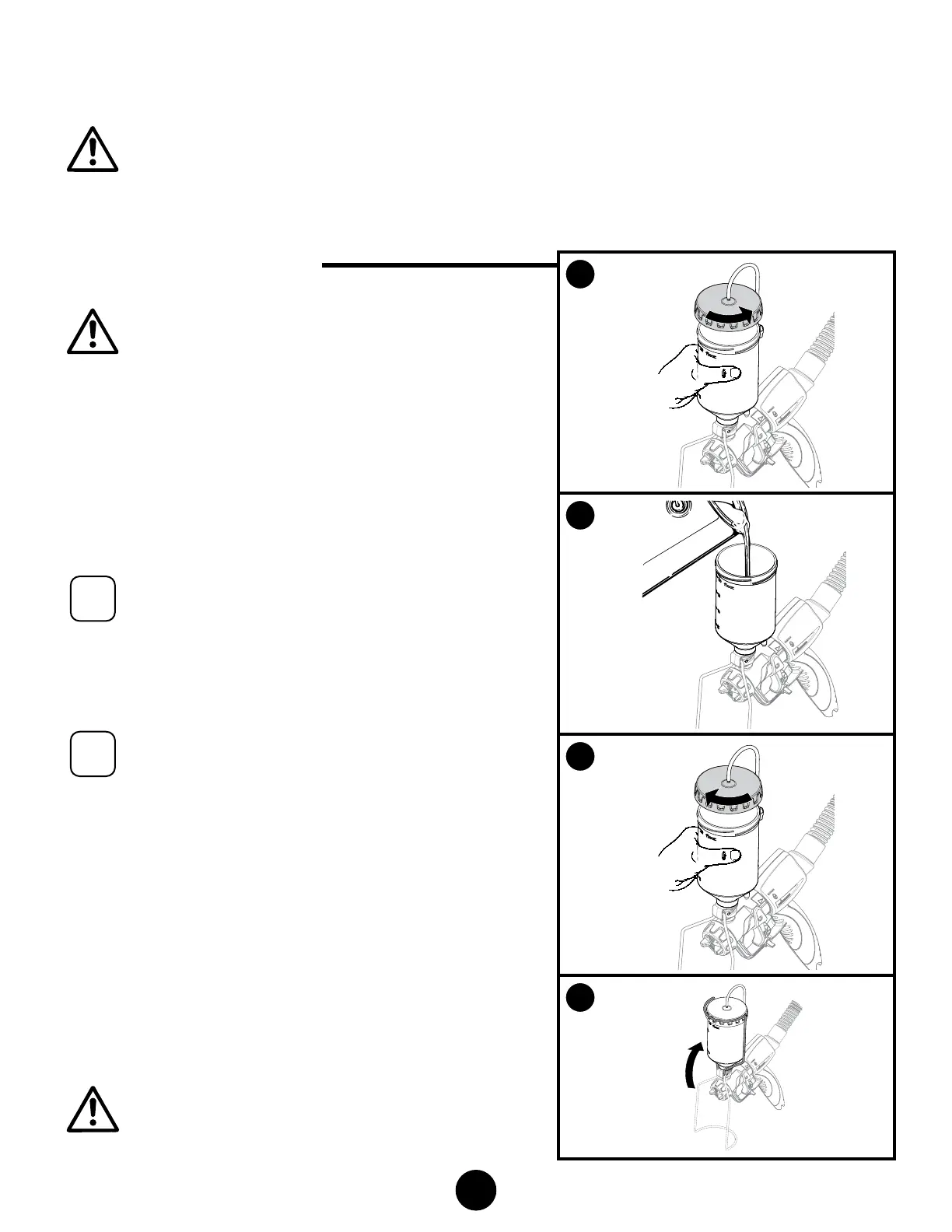

FILLING THE GRAVITY CONTAINER

tention

Make sure the power cord is unplugged.

Never remove the container from the spray gun

when it has material in it. Material will leak out.

1. Hold the container steady with one hand, and unthread

the container lid (with air tube still attached).

Make sure not to allow the container to loosen on the

spray gun.

2. After the material has been properly thinned* (if necessary)

and strained, ll the container to desired level.

3. Reattach the container lid. Tighten by hand.

The lid must be on tight in order to build air

pressure in the container and spray properly.

4. When ready to spray, the stand can be put back into the

upright position so that it does not interfere with the spray

nozzle.

Set the stand back into its lower position

whenever the spray gun needs to be set down.

DO NOT set the gravity feed nozzle down on its

side as it may leak.

*THINNING THE MATERIAL

For certain spraying situations or desired nishes, thinning the

material may be desired. It is not necessary for most materials

when used with the iSpray nozzle. For use with the Gravity

Feed nozzle thinning may be needed to acheive a ner nish.

Make sure you adjust the X-Boost™ and Material ow settings

for your specic material needs.

If thinning is necessary, use the proper solvent as specied by

the material manufacturer. Never exceed the thinning advice

given by the coating manufacturer.

Do not thin with materials that have a ashpoint

below 100°F (38°C).

tention

The gravity feed nozzle can be unstable when

in the stand position. Take care to not knock it

over when lling or any time material is inside

the container.

Loading...

Loading...