Maintenance Instructions LUBRICATION

41

IMPORTANT: Check the dipstick reading be-

fore adding the last 1/2 pint of oil and ll only to

the FULL mark. The oil level should never be

over the FULL mark on the dipstick; overfilling

CAN result in engine overheating and loss of

power.

10. Start the engine and check for oil leaks around

the oil filter. Stop the engine, recheck the oil

level, and add oil if necessary. (When the en-

gine is first operated with a new oil filter, the oil

level drops slightly as the filter is filled with oil.)

Grease Fitting and Oil Point Lubrication

Lubricate the grease fittings and oil points after ev ery

25 hours of operation. Lubricate more often when

operating in dusty or dirty conditions. Use SAE

general purpose lithium or molybdenum base grease

for grease fittings and light machine oil (SAE 10) to

lubricate oil points. Lubricate the locations shown

in the Chassis and Deck Lubrication Points

illustration.

NOTE: PTO universal joints (on the deck and trac-

tor) require routine lubrication after every 25 hours

of running time.

NOTE: The flange bearings on the PTO drive shaft

are sealed and do not require periodic maintenance.

PTO U-Joint Lubrication

DANGER

Never perform the following steps with the

engine running.

1. Remove deck from tractor.

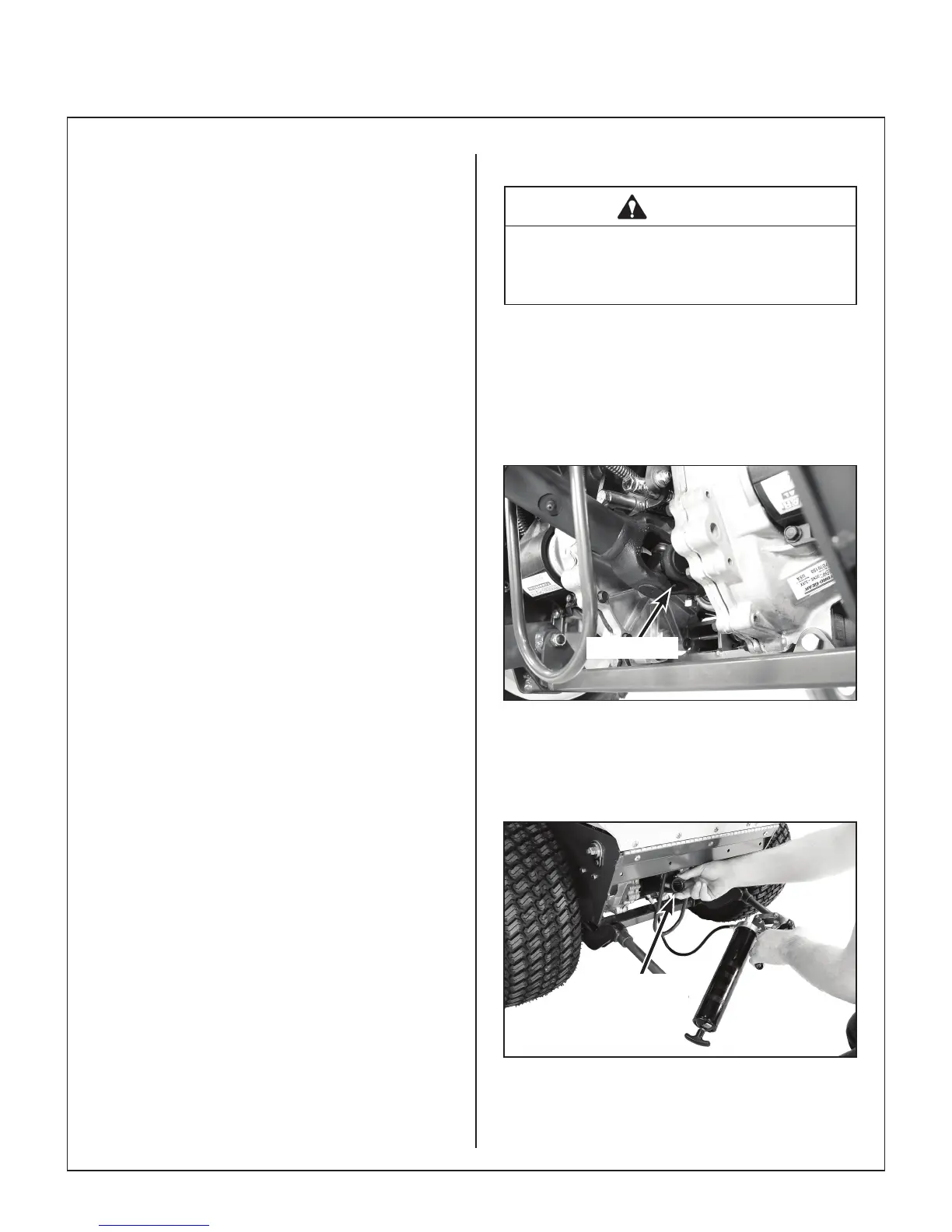

2. Position the PTO U-joint grease zerk pointing

down, as shown below. To rotate the PTO, the

blade brake will need to be released by pushing

the blade clutch lever slightly forward while si-

multaneously turning the PTO.

Grease Zerk

Grease Zerk Location

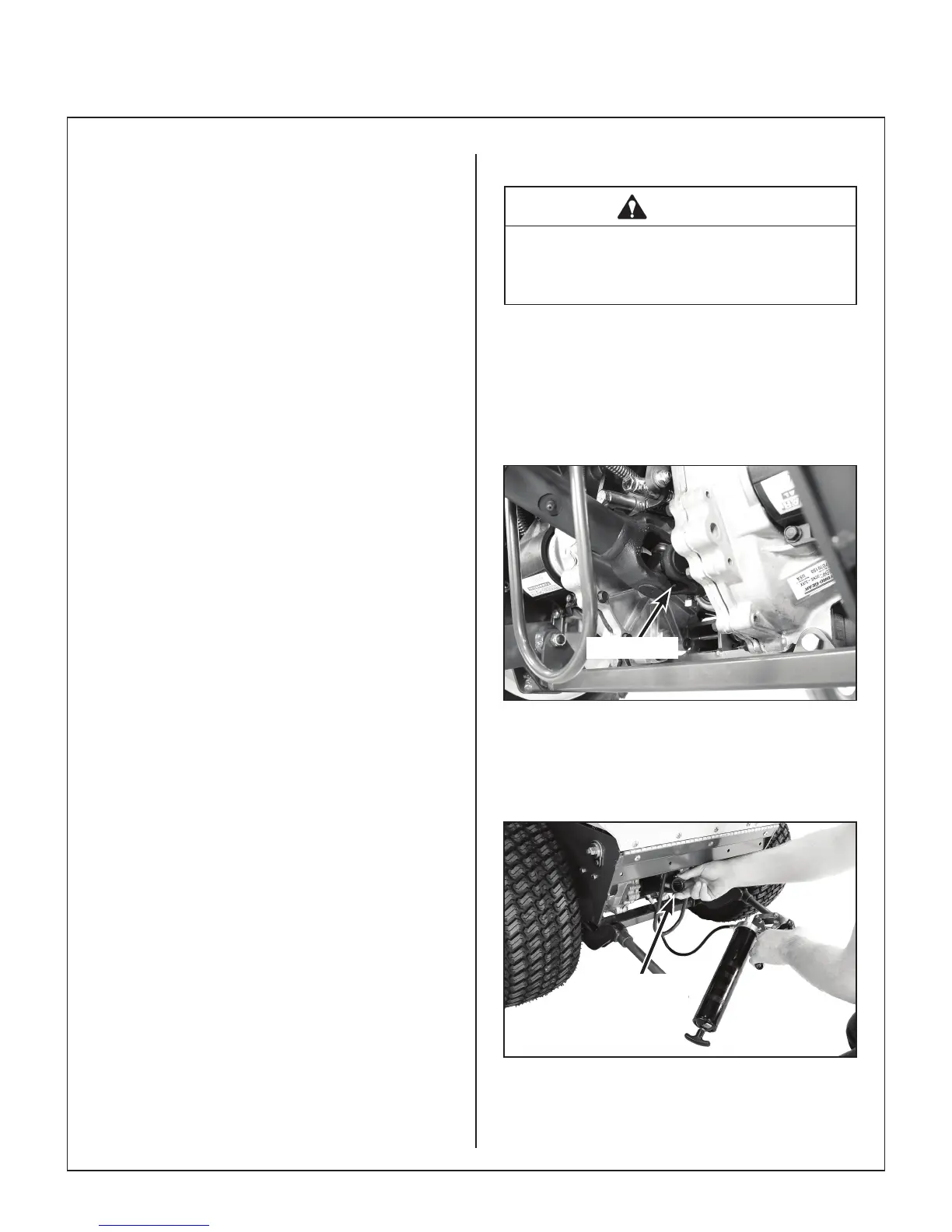

3. Use a grease gun to add grease until it seeps

out of the seals. Wipe away any excess grease.

DO NOT over grease.

Hold Tube Up to

Access Zerk

Using Grease Gun

Loading...

Loading...