The diameter of the pipe shall be large enough to avoid excessive back pressure. Other possible

equipment in the piping must also be designed and dimensioned to avoid excessive flow

resistance.

A condensate trap must be fitted on the vent pipe near the engine.

The connection between engine and pipe is to be flexible.

Design data:

see Technical dataFlow

see Technical dataBackpressure, max.

80°CTemperature

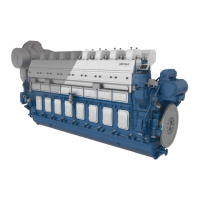

Fig 7-7 Condensate trap

(DAAE032780B)

The size of the ventilation pipe (D2) out

from the condensate trap should be

equal or bigger than the ventilation pipe

(D) coming from the engine.

For more information about ventilation

pipe (D) size, see the external lubricating

oil system drawing.

The max. back-pressure must also be

considered when selecting the ventilation

pipe size.

7.5 Flushing instructions

Flushing instructions in this Product Guide are for guidance only. For contracted projects,

read the specific instructions included in the installation planning instructions (IPI). The fineness

of the flushing filter and further instructions are found from installation planning instructions

(IPI).

7.5.1 Piping and equipment built on the engine

Flushing of the piping and equipment built on the engine is not required and flushing oil shall

not be pumped through the engine oil system (which is flushed and clean from the factory).

It is however acceptable to circulate the flushing oil via the engine sump if this is advantageous.

Cleanliness of the oil sump shall be verified after completed flushing.

7.5.2 External oil system

Refer to the system diagram(s) in section External lubricating oil system for location/description

of the components mentioned below.

The external oil tanks, new oil tank and the system oil tank (2T01) shall be verified to be clean

before bunkering oil.

Operate the separator unit (2N01) continuously during the flushing (not less than 24 hours).

Leave the separator running also after the flushing procedure, this to ensure that any remaining

contaminants are removed.

Wärtsilä 46F Product Guide - a19 - 1 December 2017 7-15

7. Lubricating Oil SystemWärtsilä 46F Product Guide

Loading...

Loading...