64659-001 REV. A 07/06/18

17

Dip Switches

Note: When power is first applied to the iHEAT control system, a 30 second delay will occur before the

system will initiate an attempt to light the burner. No gas will flow during this wait time.

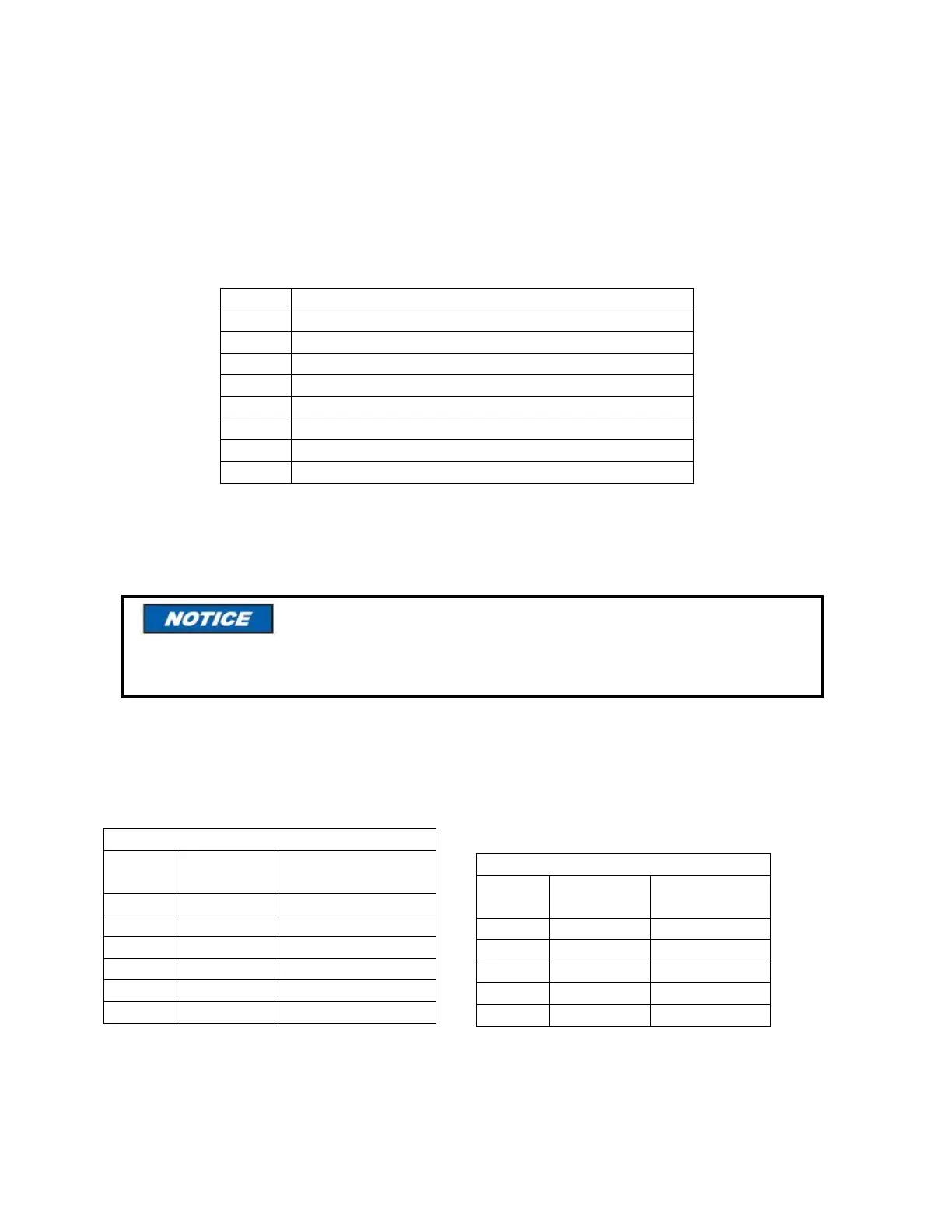

The dip switches at the bottom right corner of the iHEAT board allow changes to the board’s

configuration to be made in the field without reprograming, including switching from natural gas to

propane. To change these settings, turn off power to the board, then set the dip switches according to

the table below.

OEM specific, manual control enclosure, natural gas

OEM specific, manual control enclosure, LP gas

OEM specific, automatic control enclosure, natural gas

OEM specific, automatic control enclosure, LP gas

Low fire setting used for gas pressure setting

Table 6 - Dip Switch Settings

Modulating Valve

Adjusting the modulating valve requires that power be connected to the control board and gas be

connected to the valve. Use a manometer to measure the outlet pressure. Set the high pressure setting

before the low pressure setting. The valve must be mounted with the modulating coil horizontal.

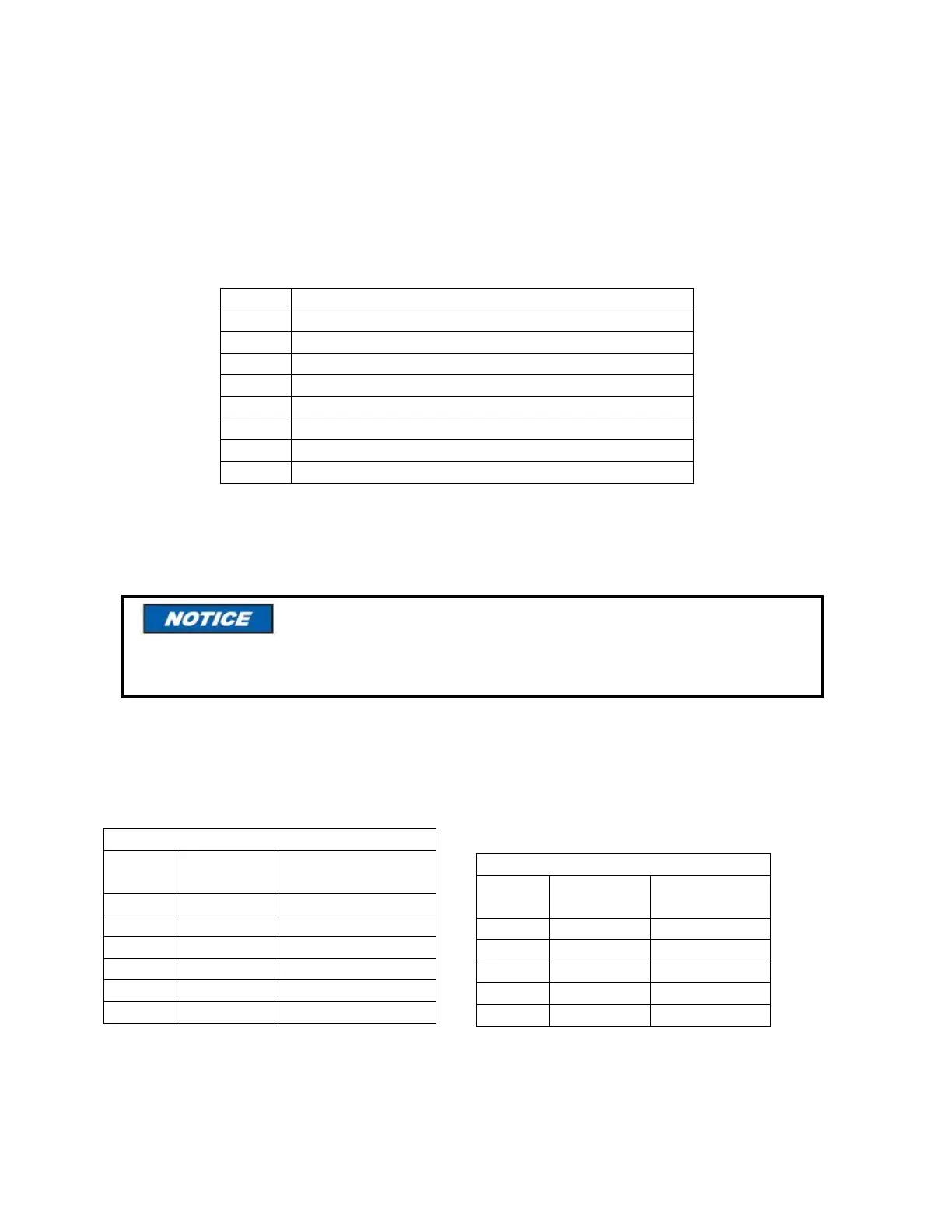

The gas valve controls the pressure of the gas supplied to the burner in order to adjust the burner’s

firing rate. The gas valve will not be able to supply enough gas to achieve the desired firing rate if the gas

line feeding it does not have sufficient pressure. The table below lists the supply pressures necessary to

support different firing rates.

Min. Inlet Pressure required for LP Gas

Min. Inlet Pressure required for Natural Gas

Table 7 - Minimum Inlet Pressure for Natural Gas Burners Table 8 - Minimum Inlet Pressure for LP Burners

The maximum rated inlet pressure to the gas valve is ½ psi (14” w.c.). The valve will be damaged

if higher gas pressure is applied.

Loading...

Loading...