上海维宏电子科技股份有限公司

SHANGHAI WEIHONG ELECTRONIC TECHNOLOGY CO., LTD.

36 / 116

a. In the Positioning Axis area, select a positioning axis.

b. In the Laser Interferometer area, set related parameters, and click Generate.

The results automatically show in Location Program area.

c. Click Run. The machine tool moves according to the generated positioning

program and the system records position data at the measuring points.

d. Save the data as a RTL or LIN compensation file in the laser interferometer.

4. Close the software, and double-click NcTune in the installation directory

C:\Program Files\Weihong\NcStudio\Bin.

5. Optional: In the menu bar, go to 帮助 > 语言 to switch to English.

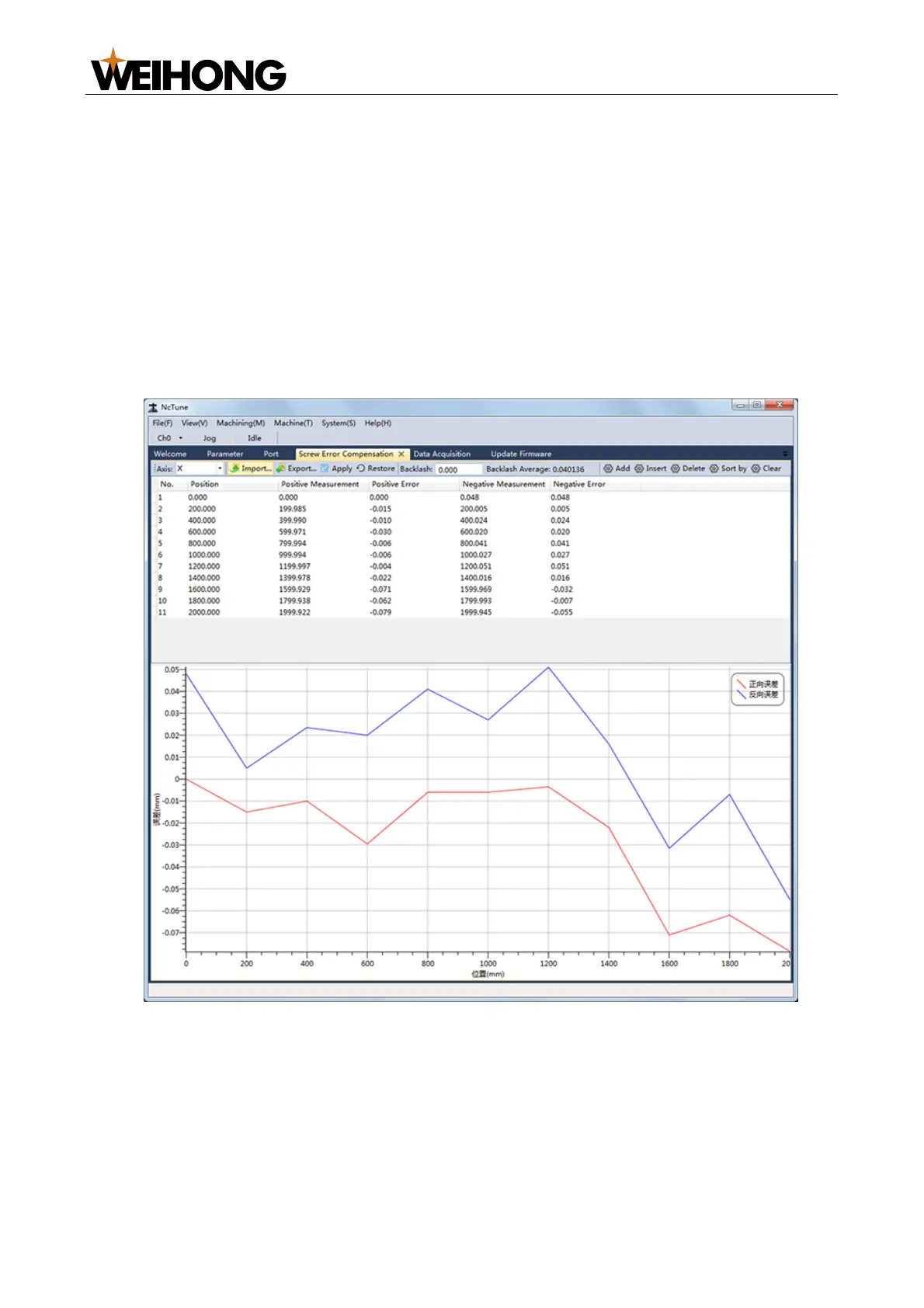

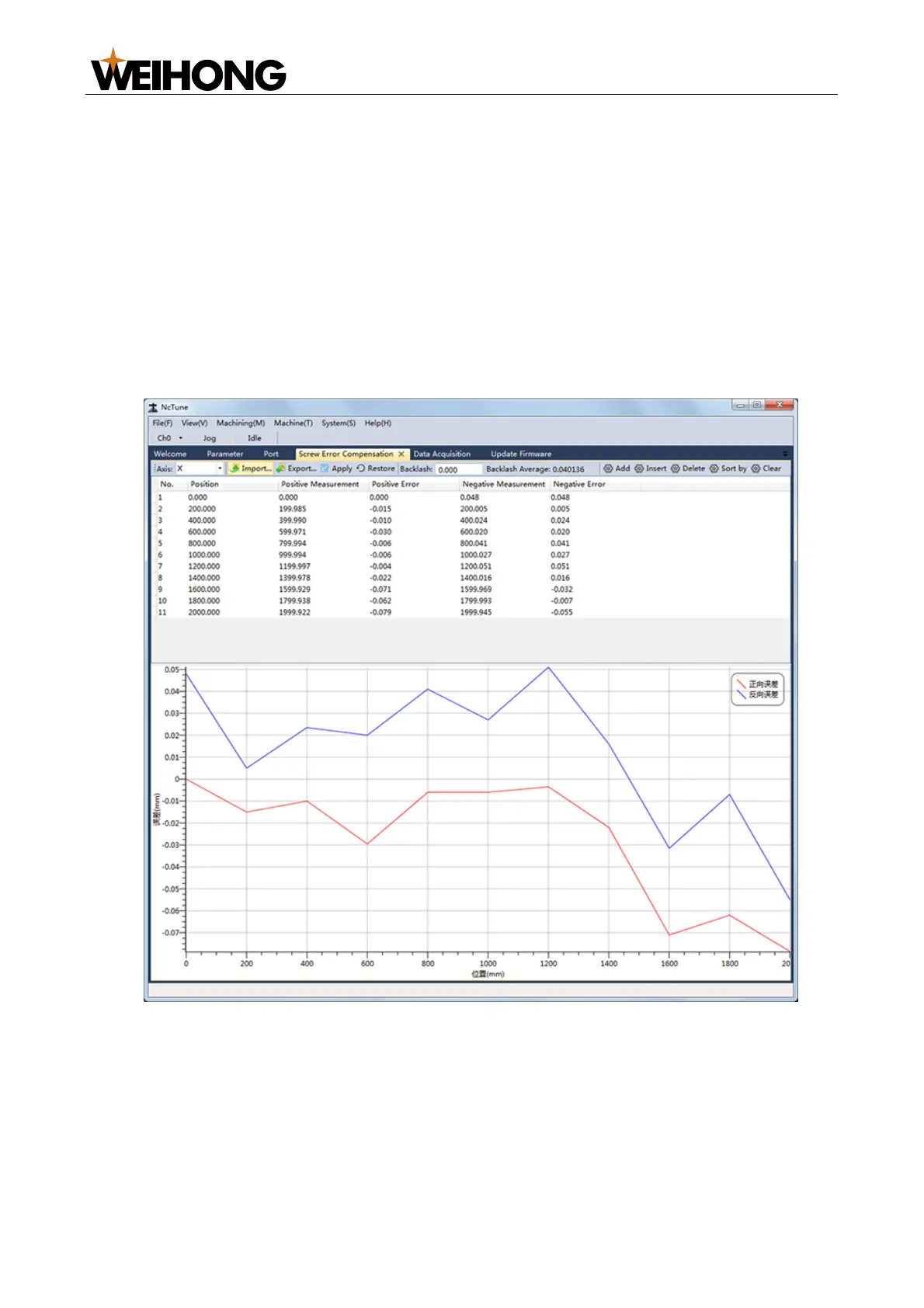

6. To enter Screw Error Compensation page, select Screw Error in the Welcome

interface.

7. To import a compensation file, click Import. NcTune generates the error curve

according to the file:

Red curve: positive error; blue curve: negative error.

8. Click Apply. The system automatically saves the compensation data to the

corresponding configuration file.

Restart NcStudio to make the setting effective.

During machining, the system automatically compensates the screw error according to the

compensation data.

Loading...

Loading...