Weldforce 202T AC/DC

© Weldclass 2020 | E.&O.E. 17

4.5.5 Base Amps (7e)

Base Amps (or Base Current or Trough Current or I

1

) is only available in Pulse or Bi-Level modes.

In Pulse & Easy Pulse mode: This is the lower amperage of the pulse wave, adjustable 1 - 100A.

See 12.3.3 for more information.

In Bi-Level mode: This is the second current setting that can be toggled to during welding, adjustable 5-

198A

4.5.6 Frequency (7f)

In Pulse & Easy Pulse mode: Frequency (Hz) sets the pulse frequency (the rate that the welding output

alternates between the Main and Base Amp settings). Setting is measured in number of cycles per

second (Hertz). Adjustable 1 - 99 Hz.

See 12.3.3 for more information.

In AC with Pulse Off: Frequency (Hz) sets the frequency of the AC welding current (the rate that the

welding output alternates between forward and reverse current flow). Setting is measured in number

of cycles per second (Hertz). Adjustable 10 - 200 Hz.

4.5.1 Balance (7g)

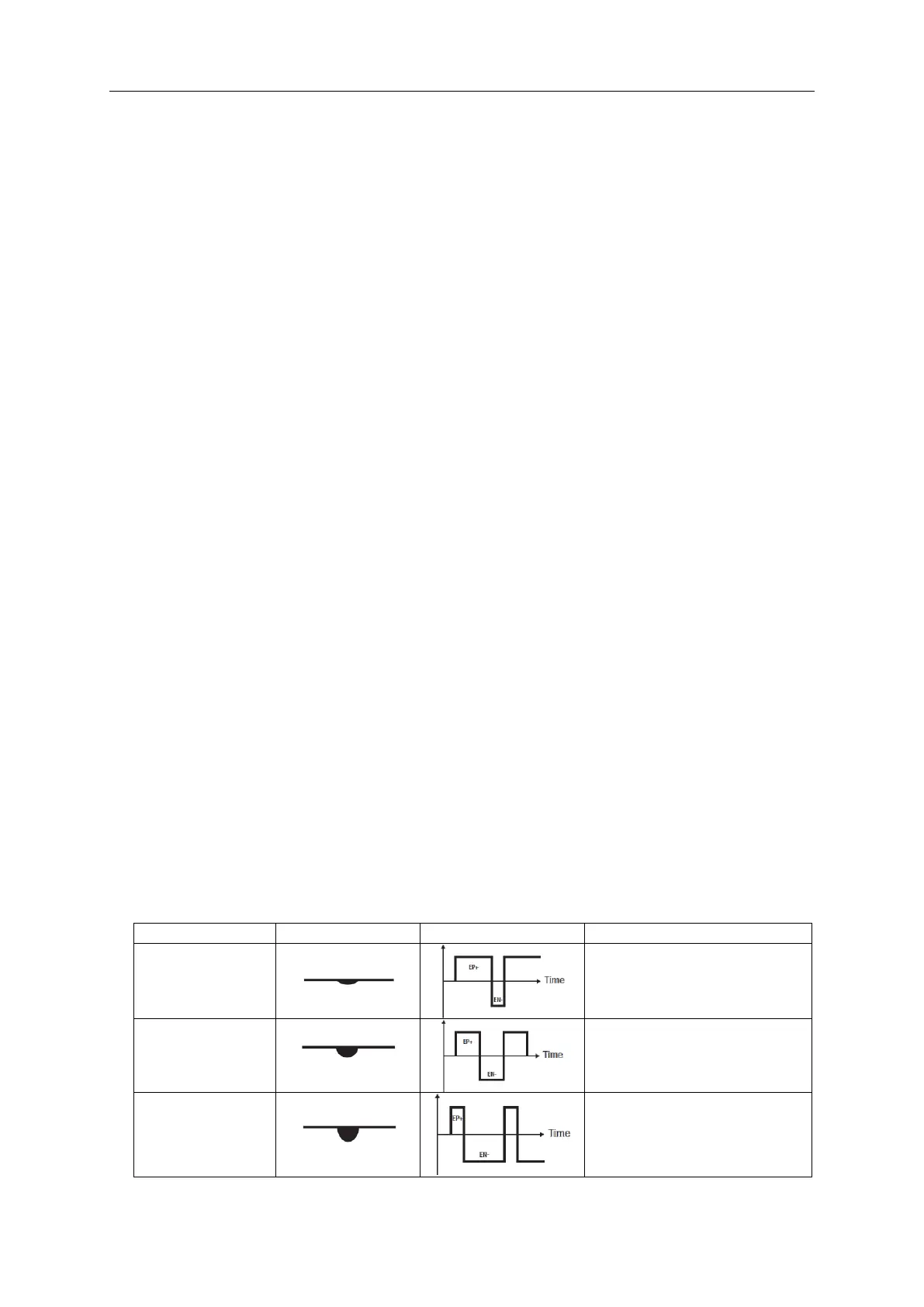

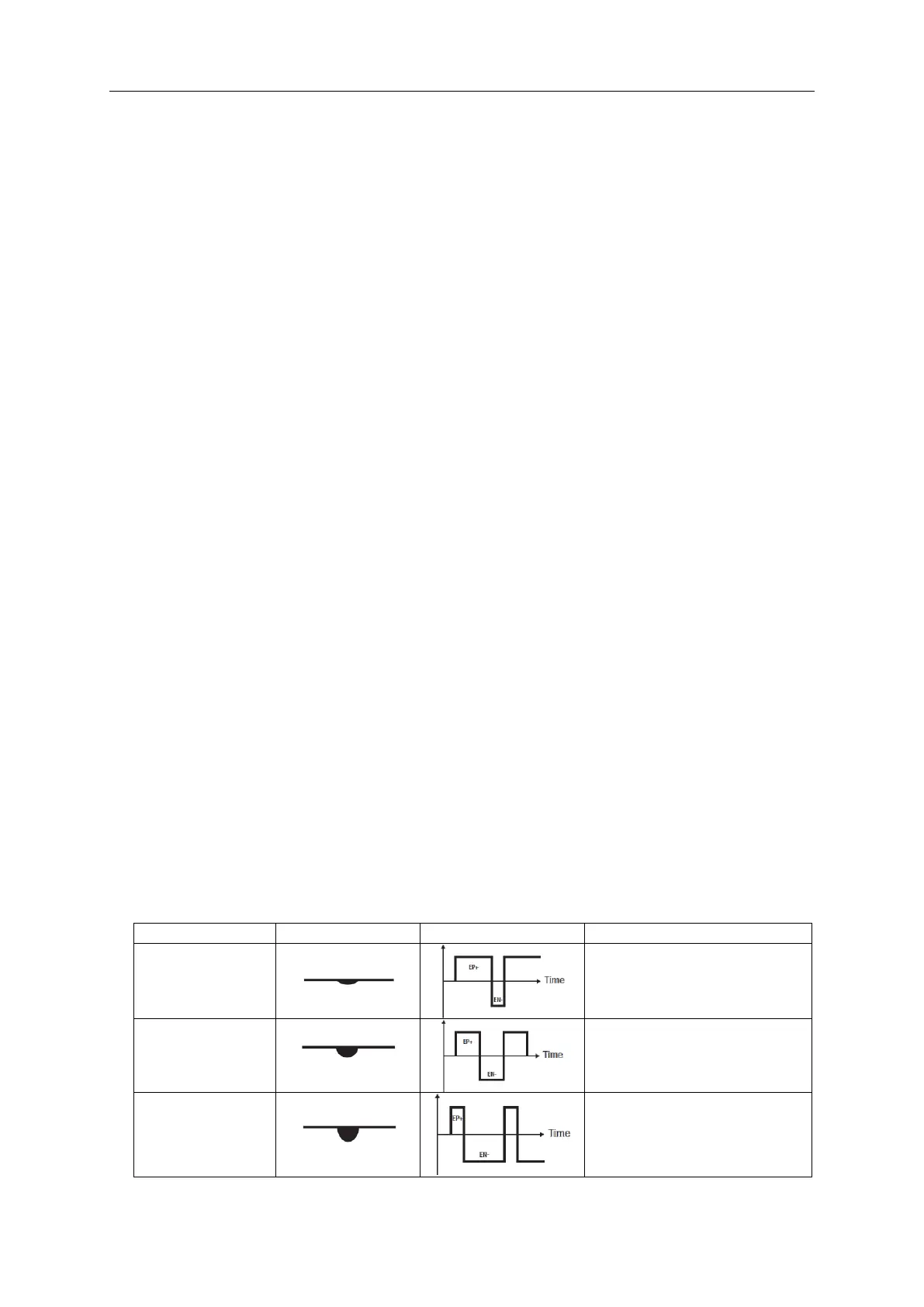

In Pulse & Easy Pulse mode: Adjusts the ratio (1-99%) between the time during which the current is at

its highest level (main welding current) and the total pulse cycle period/time. This adjustment is often

referred to as Pulse Width. See 12.3.3 for more information.

In AC with Pulse Off: Adjusts the balance (-80 to +80%) between the forward and reverse current cycles

when welding in AC output mode. The reverse part of the AC cycle gives the ‘cleaning’ effect on the

weld material, while the forward cycle melts the weld material. Neutral setting is 0.

Increased reverse cycle bias (positive settings) will give greater cleaning effect, less weld penetration

and more heat in the torch tungsten. This gives the disadvantage of reducing the output current that

can be used for a given tungsten size to prevent the tungsten overheating.

Increased forward cycle bias (negative settings) will give the opposite effect, less cleaning effect, greater

weld penetration and less heat in the tungsten.

Ideally for maximum effectiveness, the clean width/ AC balance should be set with as much forward

cycle bias as possible, while still maintaining a sufficient level of oxidisation removal for a contamination

free weld pool. The cleaner the non-ferrous metal is before welding, the more effective it is to weld.

This effect can also be used to reduce heat in the tungsten, allowing use of a pointed tungsten tip shape

for a more defined arc. See 12.3.4 for more information.

Loading...

Loading...