Weldforce 202T AC/DC

© Weldclass 2020 | E.&O.E. 51

12.3.4 AC Balance

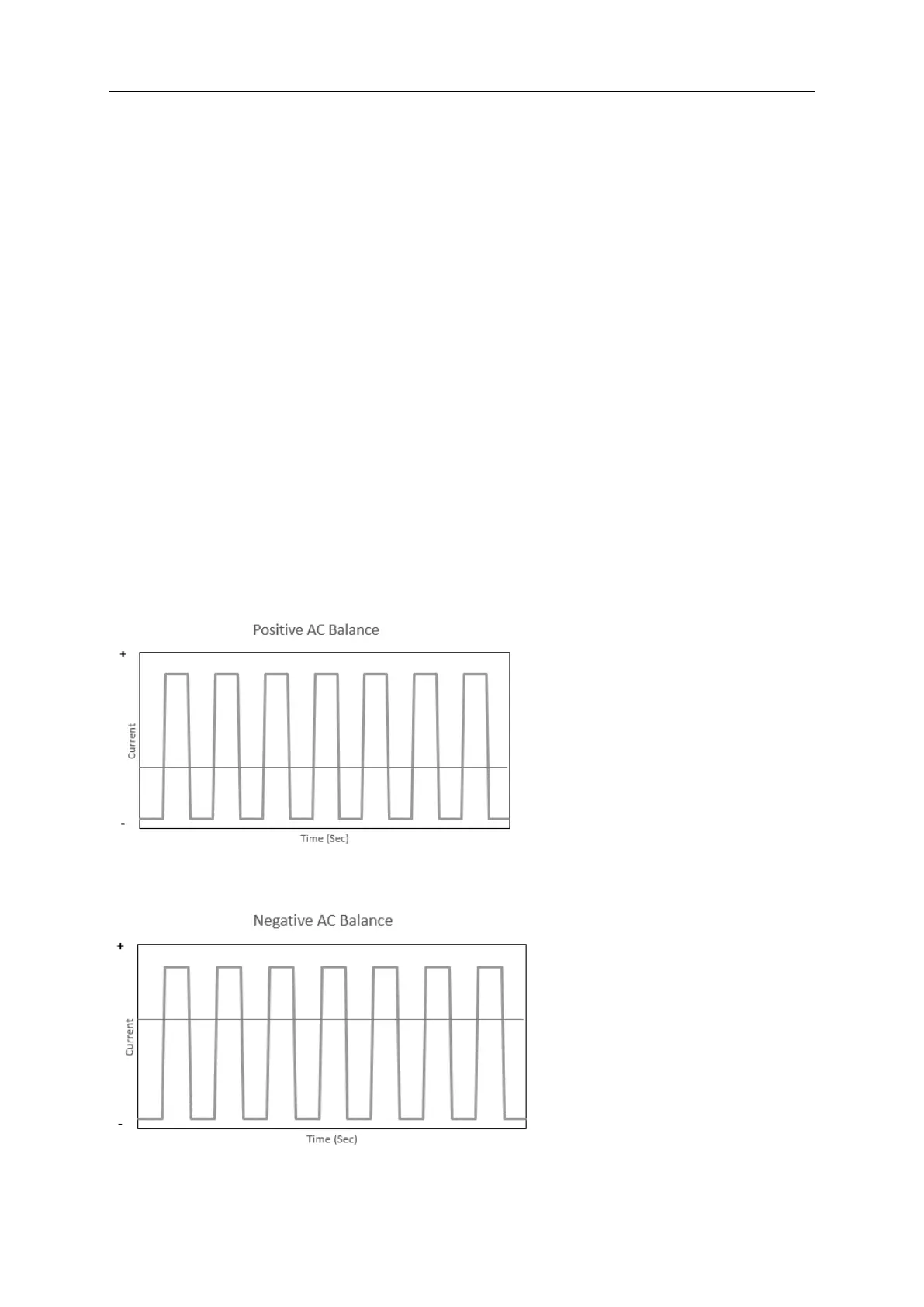

AC Balance is used to vary the proportion of time that the weld current flows in each direction.

The reverse part of the AC cycle is what breaks the oxide layer and ‘cleans’ the weld material.

The forward cycle is what actually melts the weld material.

A neutral AC Balance setting is 0 which means that the currently is flowing forwards for 50% of the time

and in reverse for 50% of the time.

More Positive AC Balance will mean will give greater cleaning effect, less weld penetration and more heat

in the Tungsten Electrode.

This gives the disadvantage of reducing the output current that can be used for a given tungsten size to

prevent the tungsten overheating.

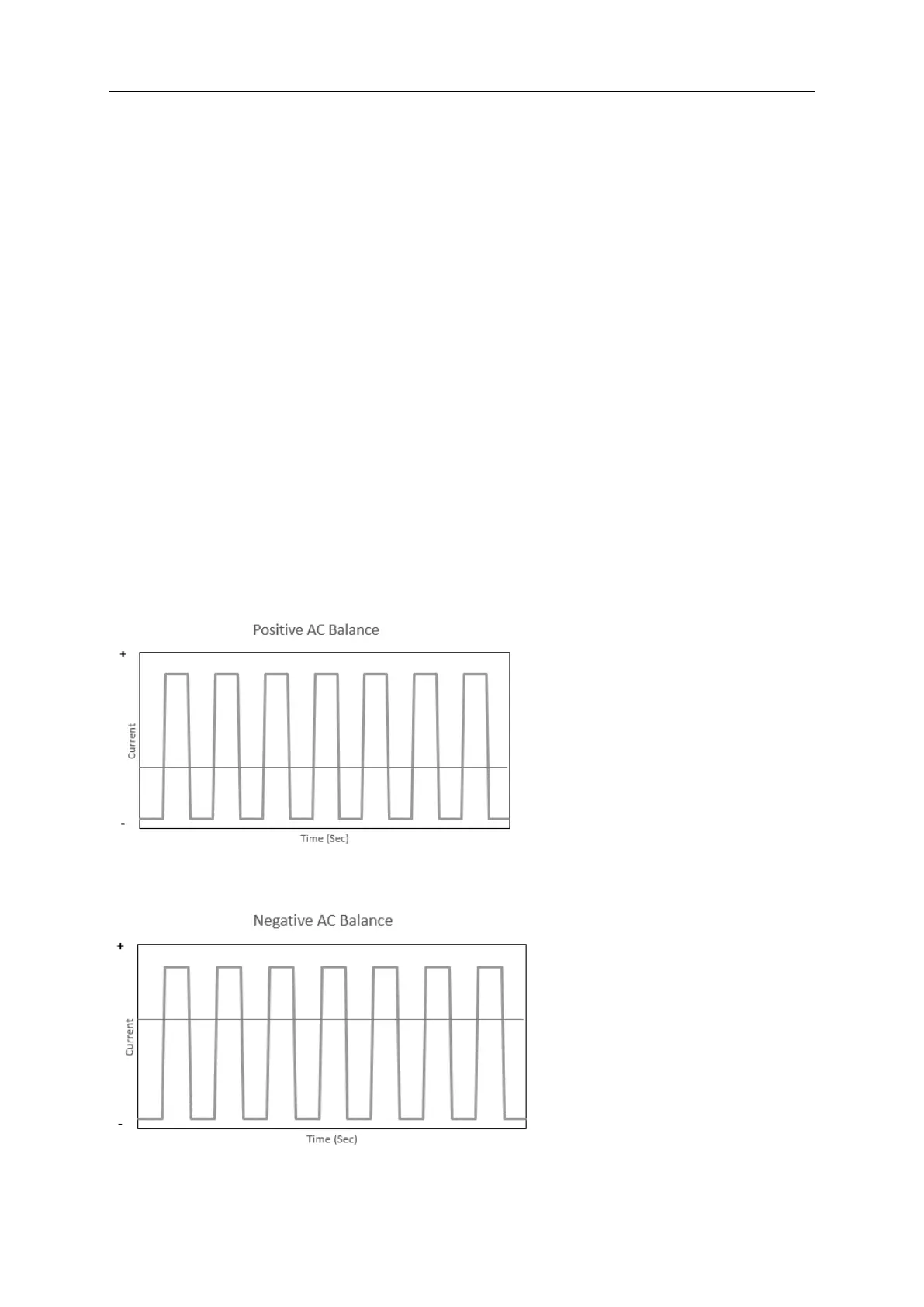

More Negative AC Balance will give the opposite effect, less cleaning effect, greater weld penetration and

less heat in the tungsten.

Ideally for maximum effectiveness, AC balance should be set with as much Negative AC Balance as possible,

while still maintaining a sufficient level of oxidisation removal for a contamination free weld pool.

The cleaner the non-ferrous metal is before welding, the more effective it is to weld.

This effect can also be used to reduce heat in the tungsten, allowing use of a pointed tungsten tip shape for

a more defined arc.

Figure 50

Figure 51

Loading...

Loading...