Page 13

OPERATION–Key Points to Feeding the

Welding Wire

ALWAYS EXTEND THE MIG TOURCH LEAD FULLY WHEN FEEDING THE WIRE

THROUGH THE TORCH TIP

Always ensure that you always extend the welding torch lead to enable the MIG

wire to pass through the welding torch lead inner tube. The inner tube allows the

MIG wire to pass between the MIG welder and the welding torch without creating

drag. Ensure that the torch lead is not curled up or tightly wound as this can cause

the welding wire to pierce through the inner tube and protrude through the outer

protective layer of the torch lead.

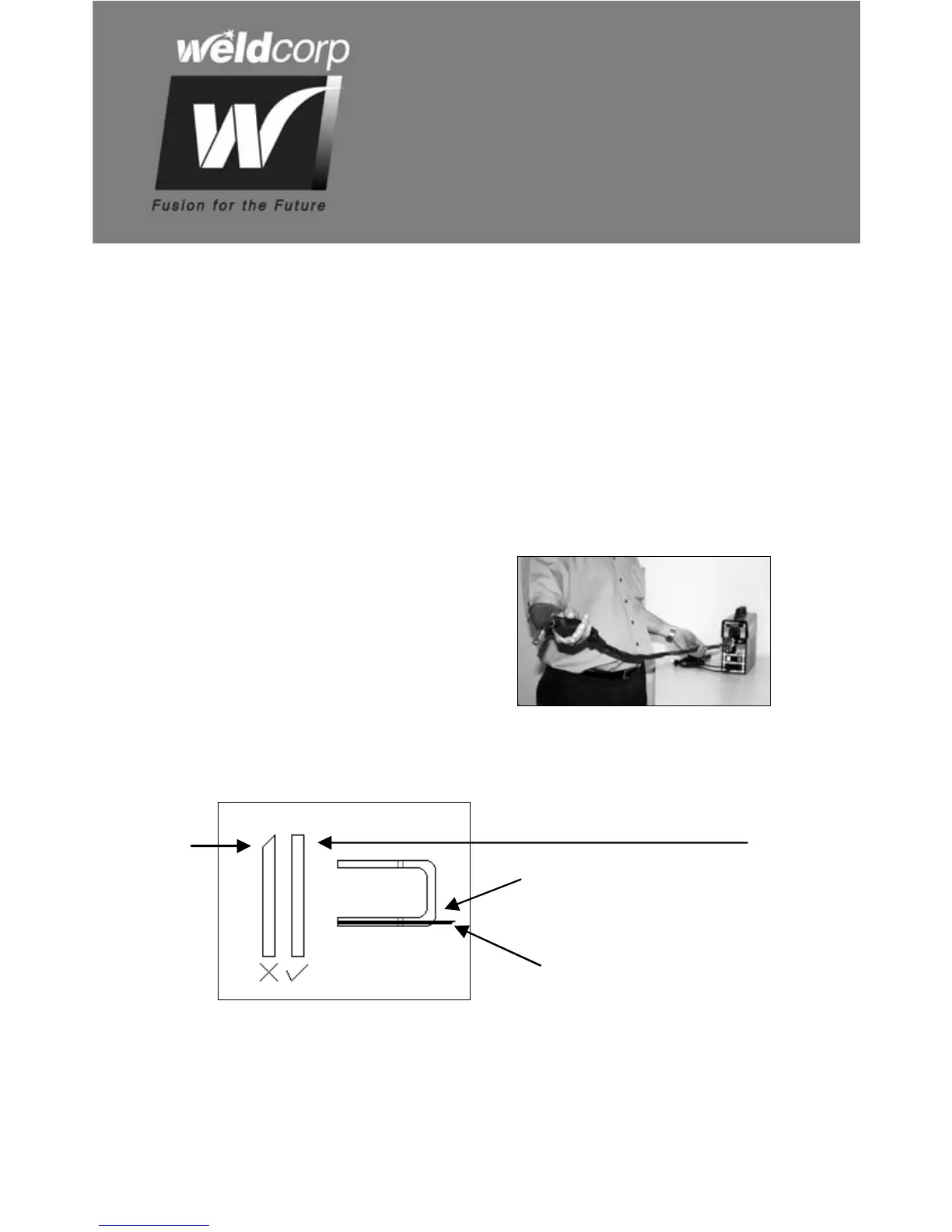

ALWAYS CUT THE WELDING WIRE WITH A FLAT END

Welding

wire with a

sharp point

Welding

wire with

a flat end

Welding wire with a

sharp end protruding

Welding wire protrud-

ing through inner tube

due to a curved hose

ALWAYS REMOVE THE MIG TORCH TIP PRIOR TO FEEDING THE WIRE

THROUGH THE TORCH

Loading...

Loading...