:t~

Pick-up Guide Wheel

The baler can be equipped with a adjustable piä-up guide wheel to have optimum

matching of pick-up to ground condi,tion even on uneven fields end to guarantee

clea,n picking up of baling materi.ail.Order number 1121.42.93.00.The gU'idewheel

can be adjusted :in heighrt as requested. Set pick-up so thai fines have a ground

alearance of approx. 2 cm (fig. 14). Observe correot Irre pressure of 11.5bar.

Baler-Mounted Bale Thrower P 23

is mounted to the end of the bale chamber. It loads the boles on to an allached

trailer with special body extension. Economical one man operation where baling

end loading is doneat the same time. The acreage covered is increased by up

to 40%.

ASSEMBLY: at the factory when the baler is ordered with thrower allached, or

by your loGoidealer, if ordered at a leier stage.

Normal Irres of AP 38/42 should be changed against speoiallIrres, see page 8.

Service

and Lubrication

To keep the value end long life of the machine, generous lubrication end careful

regular serv,icing wil.l keep your baler at peak performance and avoid prema-

lure repairs.

General Hints: 'after the first 20 working hours, firmly fighten up all bolts and

nuts, inside and outside the machine. Timing boHs on knoller and rom sildes

shou,ld not be changed.

Usa lithium multi-purpose grease only for your grease gun. NeVer lubricate the

runni,n

,

g machine! Clean grease nipples before applying the gun. Drive greas

,

e

in until the old packing emerges from the sides of the bearings. Do not wipe

off old grease rims (dust protection I).

Service of Gears

Teeth of all spur end beye! gears should be cleaned as necessary.

Road Wheels

Check wheel nuts and Gaps and fixing bolts of wheel stub axles for light fit.

Maintain correct Irre pressure, on AP 38/42 standard Irres on both sides 2.0 bar.

On AP 48/53 standard Irres for right side 7.00-12 also 2.0 bar, on left Irre 10.0/75-

152.3 bar. Pressure for special Irres see page 8.

10

~

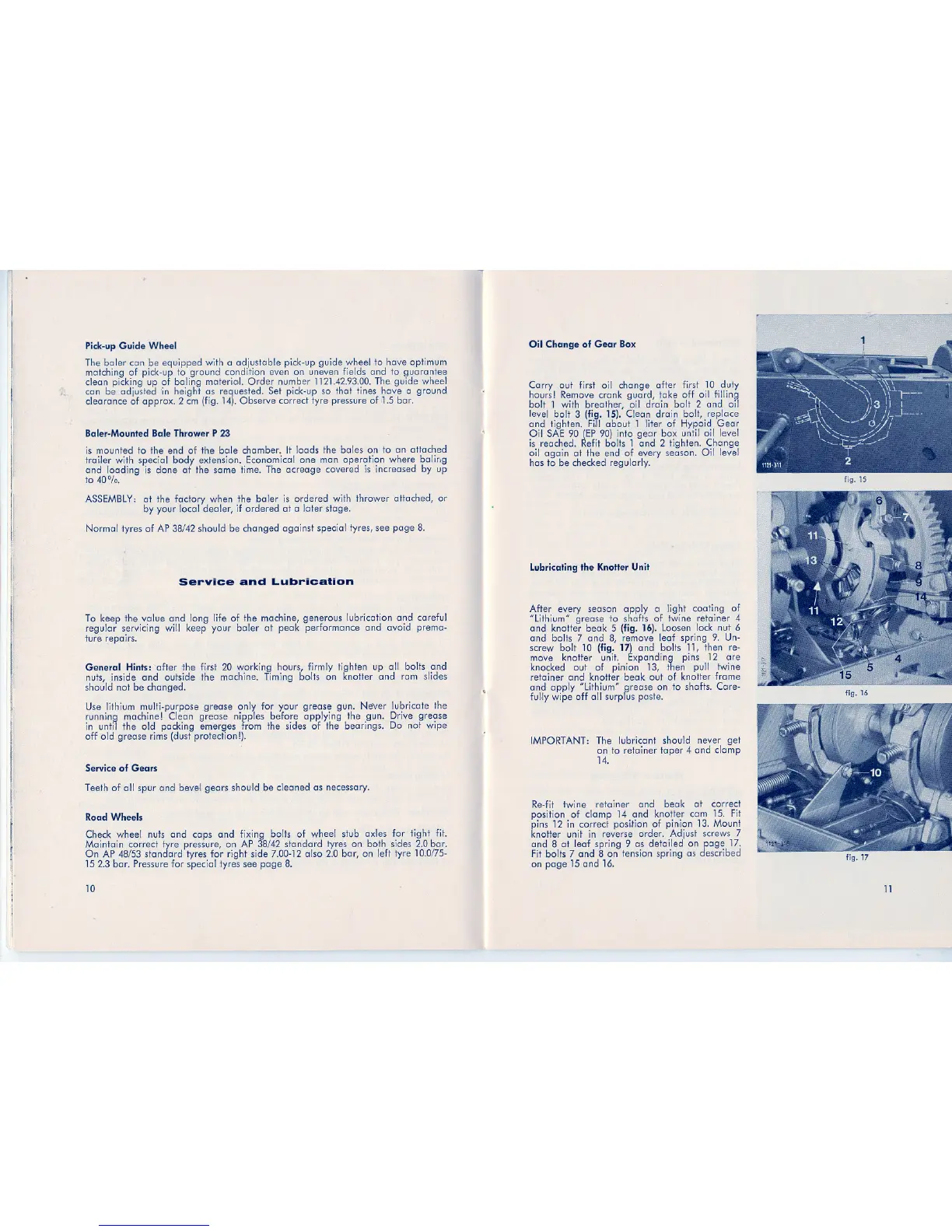

eil Change of Gear Box

Carry out first oil change after first 10 duty

hours! Remove crank guard, take off oil filling

bolt 1 with breather, oil drain bolt 2 end oil

level bolt 3 (fig. 15). Clean drain bolt, replace

and fighten. Fi.11about 1 liter of Hypoid Gear

Oi,1SAE 90 (EP 90) info geer box until oil leve,1

is reached. Refit bolts 1 and 2 fighten. Change

oll again at the end of every season. Oll level

hag to be checked regu,larly.

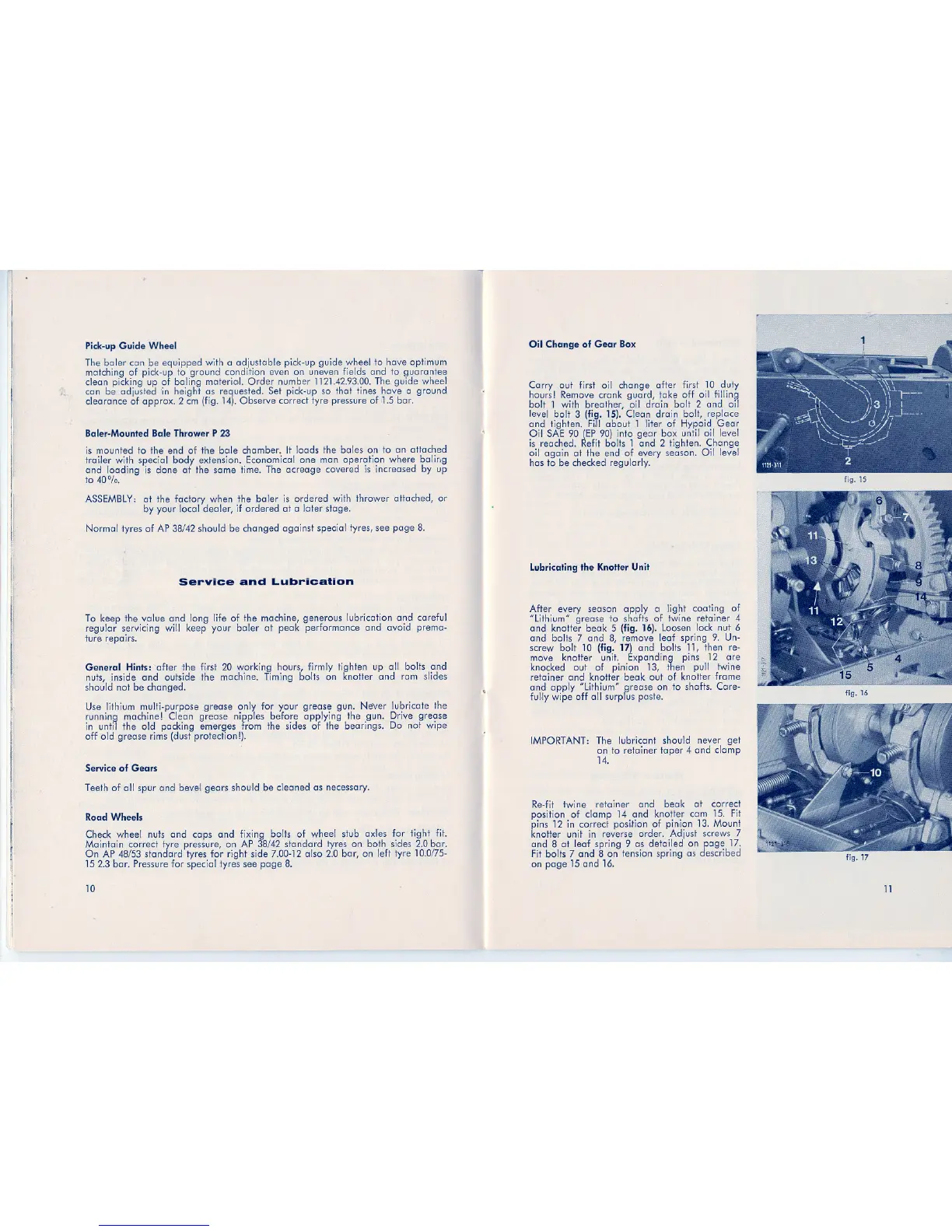

Lubricating the Knotter Unit

After every season apply a light coating of

"Lithium" grease to shafts of twine retainer 4

and knoller back 5 (fig. 16). Loosen lock nut 6

and bolts 7 and 8, remoye leaf spring 9. Un-

screw bolt 10 (fig. 17) end balls 11, then re-

moye knoller unit. Expanding pins 12 are

knocked out of pinion 13, then pull twine

retainer and knotter back out of knoller frame

and apply "Lithi'um"grease onto shafts. Care-

fuJ.lywipe off all surplus paste.

,J

IMPORTANT: The lubricant shou'ld never gel

on to retainer taper 4 end clamp

14.

Re-fit twine retainer and beak at correct

position of clamp 14 and knaller cam 15. Fit

pins 12 in correct posiJion of pinlion 13. Mount

knaller unit in reverse order. Adjust screws 7

end 8 at leaf spring 9 as detailed on page 17.

Fit balls 7 and 8 on tension spring as described

on page 15 and 16.

Ii.

fig. 15

fig. 16

fig.17

11

Loading...

Loading...