r

Safety Device tor Packer end Cross Feed

AP42 end AP 53

fig. 40

Cross feed end packer are fitted with an

automatie safety release whi,ch causes the

packer fines to swing away. If the baler be-

comes clogged or a foreign body has been

drawn on to the feed fable the fines deflect,

as in fig. 40 a end then automatically swing

back info working position (fig. 40). In that

war, the clogged baler will freeitself.

Briefly reducing PTO speed increases the'

deflection resistance in the packer linkage.

The ti,ght bunch of material is pushed info

the chamber end the machine resumes un-

obstructed working. The torque of the

deflecting cross-feed is set between 600 end

850 Nm end on top-feed between 750 end

850 Nm. The connecting rod must be fitted in 2nd. hole tram bottom of the ad-

justing bracket. If the fines swing away repeatedly, this indicates thaI the machine

is work,ing at the limit of its capa city. Engage the next lower tractor geer, as

frequent ti ne deflection increases wear of aH drive parts.

fig. 40a

IMPORTANT: If fines of c;:rossfeed end packers deflect five or six limes running

end the

,

trouble stil,1 pe

,

rsists, the obstruction 'is

,

too great to be cleared by the

automatie system. In that case, shut off the pto end clear the feed fable by hand.'

On no account, attempt to remove the obstruction by reversing the PTO dri,ve,

as this is Jiikely to band the leaf spring of the automatie clearing system out of

share.

Packer with Mechanical Overloading Safety (AP 38/48)

The AP 38/48 has a mechaniwl overloading safety device instead of a deHecting

safety device in the packer system. One hex. bo.It each M6x35 DIN 933-10.9 with

two hex. nuts M 6 DIN 934-10 are acting as shear olutch safety.

Safety of Tripping Mechanism

Unintentional tripping of knotter mechanism can be prevented if safety latch

is in position "Aus". Even if baler is running the needles will s'tay in resting

position. Operation of safety latch see page 6 end 7.

Pick-up Balance Spring

T0 avoid damage to the pick-up by travelling on uneven ground the pick-up is

equipped with a torsion spring. In working posi.tion the pick-up is ba,ianced by

the torsion sproing end will be released of its own weight to fellow the contours

of the ground.

""'I

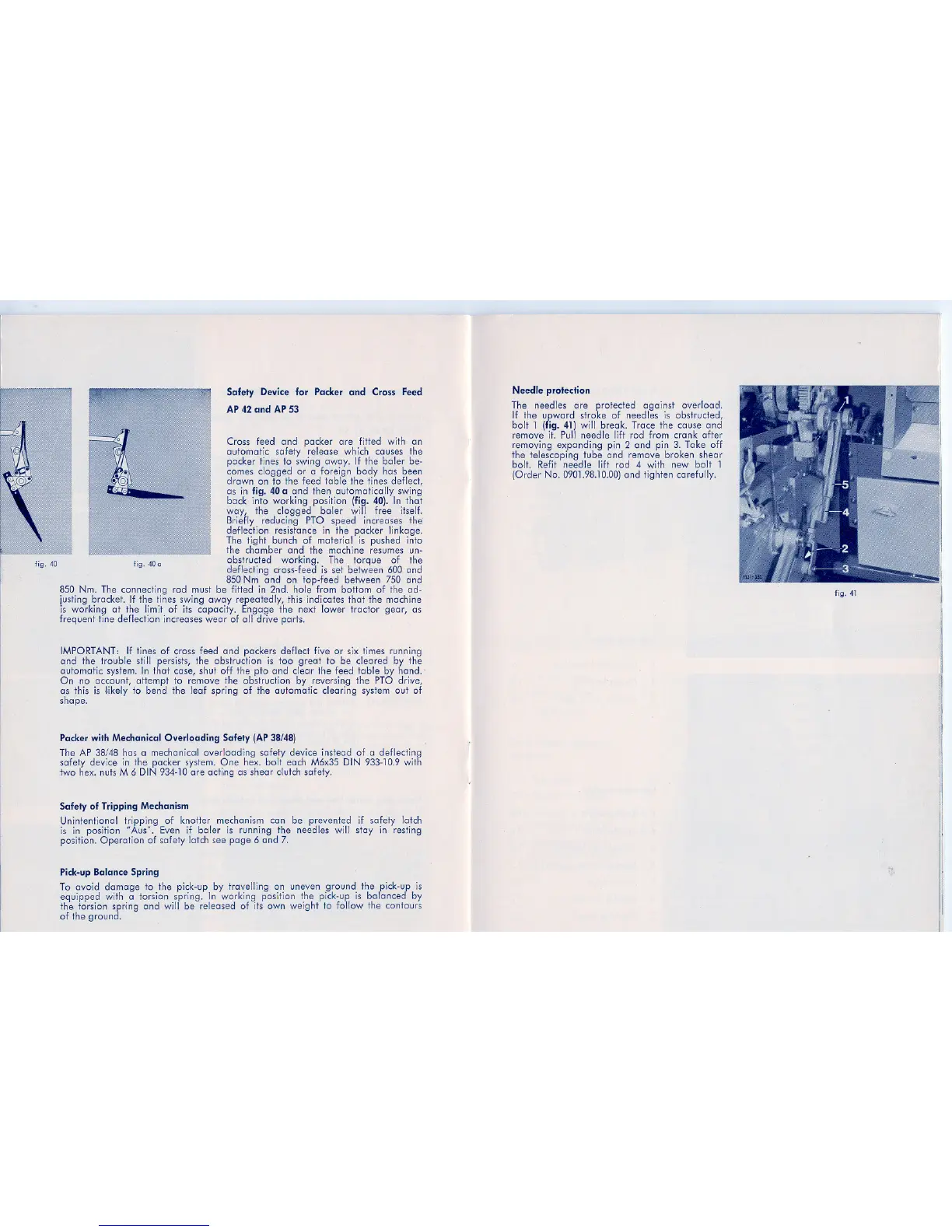

Needle protection

The needles are protected against overload.

If the upward stro

,

ke of needles is obstructed,

holt 1 (fig. 41) will break. Trace the causa end

remove it. Pul,! needle lift rod tram crank after

removing expanding pin 2 end pin 3. Take off

the te,lescop,ing tube end remove broken shear

holt. Refit needle lift rod 4 with new holt 1

(Order No. 0901.98.10.00)end fighten carefully.

~

fig. 41

il~

11

I

I

I

I

I

i

I

11

'"

Loading...

Loading...