f

~

14

Pushhex. shaft 14 out of cross lead drive

pinion 16 (fig. 23). Removecirclip 13 and also

push hex. shaft out of top feed drive pinion.

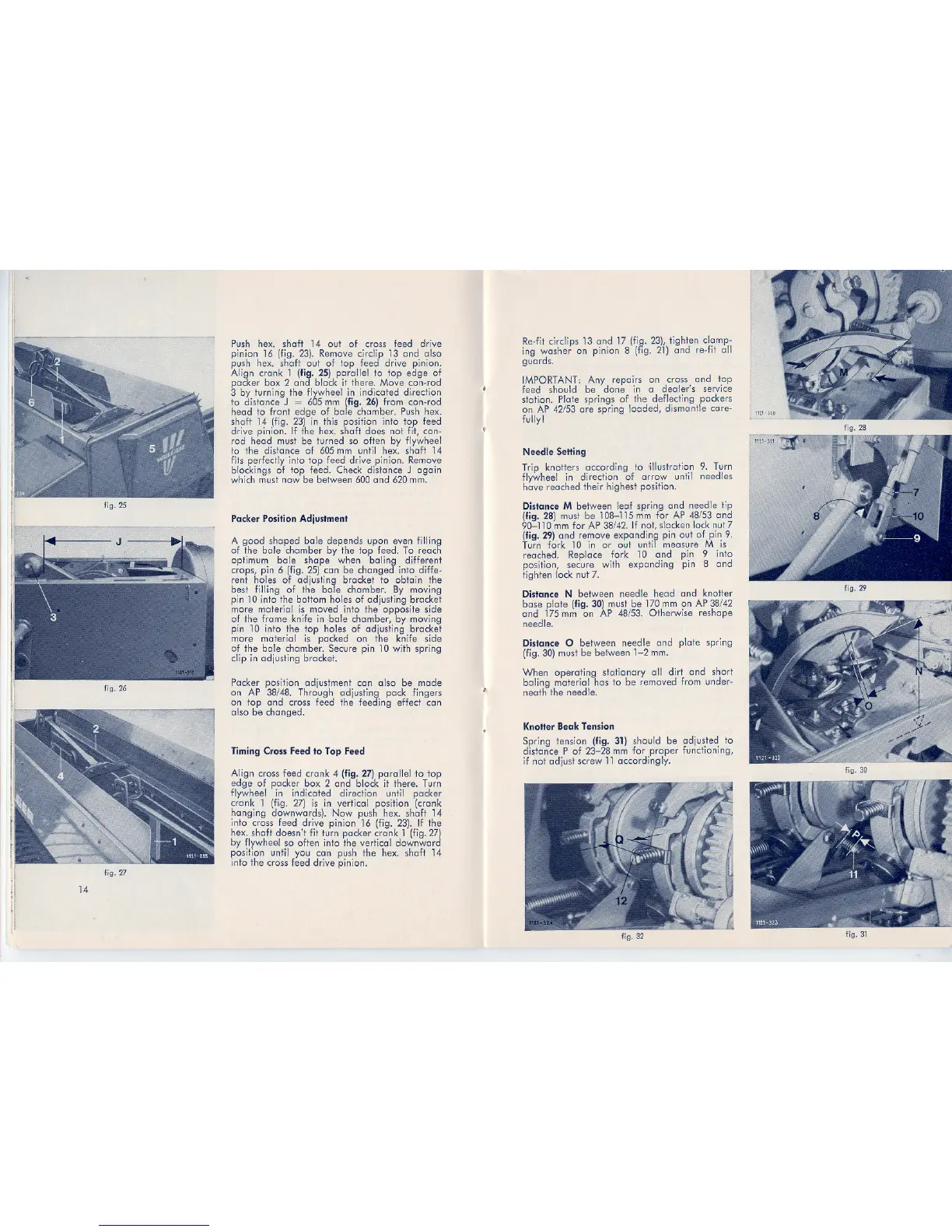

Align crank 1 (fig. 25) para-liel to top edge of

packer box 2 and block it there. Move con-rod

3 by turning the flywhee-Iin indicated di,rection

to distance J = 605 mm (fig. 26) from con-rod

head to front edge of bole chamber. Push hex.

shaft 14 (fig. 23) in this position info top feed

drive pinion. If the hex. shaft does not fit, con-

rod head must be turned so offen by lIywheel

to the distance of 605mm until hex. shaft 14

fils perfectly info top lead drive pinion. Remove

blockings of top feed. Check distance J again

which must now be between 600 end 620 mm.

Packer Position Adjustment

A good shaped bole depends upon even filling

of the bole chamber by the top feed. To reach

optimum bole shops when baling different

crops, pin 6 (fig. 25) can be changed info diffe-

rent holes of adjusting bracket to obtain the

best fi,lIing of the bole chamber. By moving

pin 10 info the bollom holes of adjusting bracket

more material is moved info the opposite side

of the frame knife in bole chamber, by moving

pin 10 info the ,top holes of adjusting bracket

more material is packed on the knife side

of the bole chamber. Secure pin 10 with spring

clip in adjusting bracket.

Packer position adjustment can a.lso be made

on AP 38/48. Through adjusting pack fingers

on top end cross lead the feeding effect can

also be changed.

Timing Cross Feed to Top Feed

Align cross lead crank 4 (fig. 27) parallel to top

edge of packer box 2 end block it there. Turn

flywheel in indicated direction until packer

crank 1 (hg. 27) is in vertiwl position (crank

hanging downwards). Now push hex. shaft 14

info cross feed drive pinion 16 (fig. 23). If the

hex. shaft doesn't fit turn packer crank 1 (fig.27)

by flywheel so offen info the vertical downward

position until you canpush the hex. shaft 14

info the cross feed drive pinion.

:t

Re-fit circlips 13 end 17 (fig. 23), tighten clamp-

ing washer on pinion 8 (fig. 21) end re-fit oll

guards.

IMPORTANT: Any repairs on cross end top

feed shou-Id be clone in a dealer's service

station. Plots springs of the deflecling packers

on AP 42/53 are spring loaded, dismant,le care-

fu'lly!

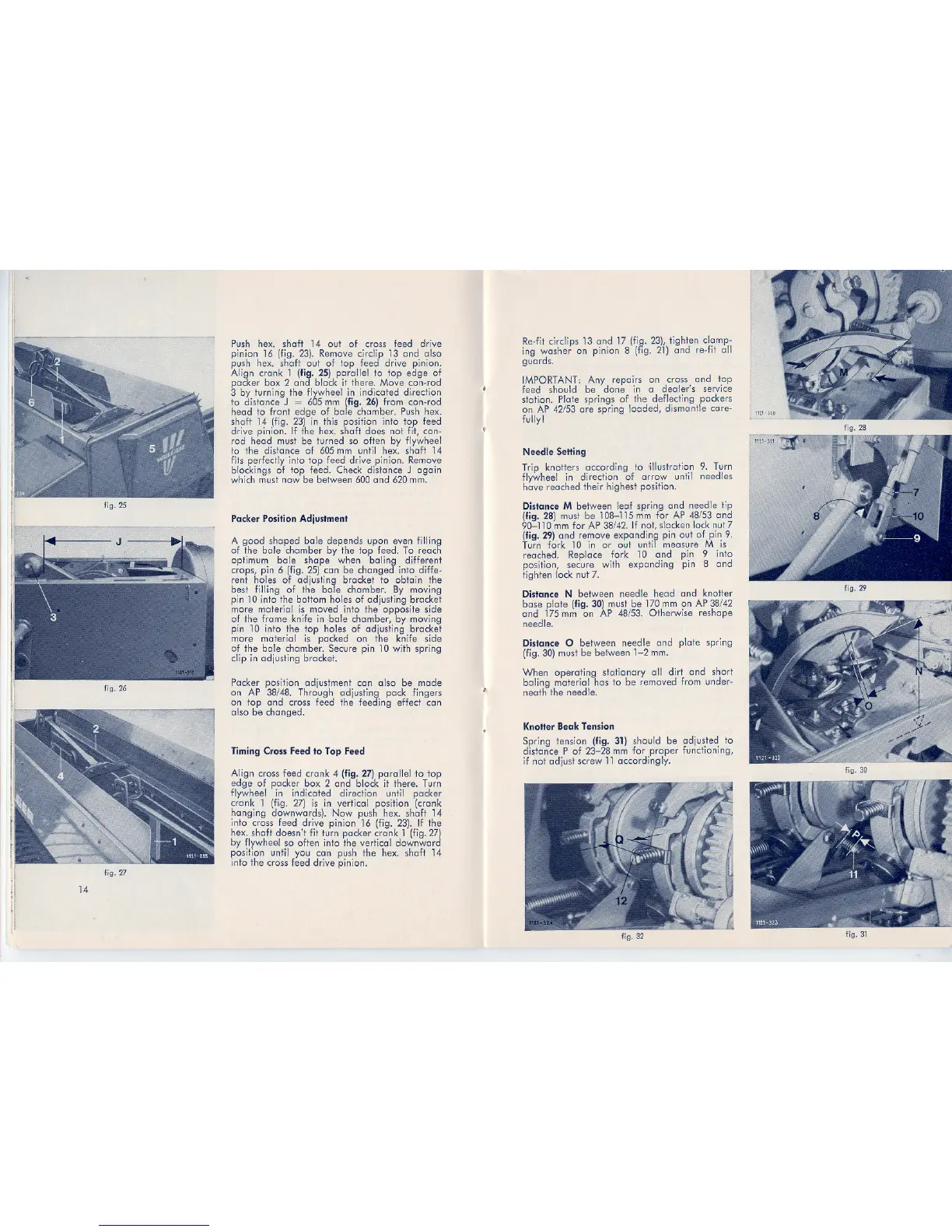

Needle Setting

Trip knollers according to 'illustration 9. Turn

flywheel in direction of arrow until needles

have reached their highest posi,tion.

Distance M betweenleaf spJing end needle tip

(fig.28) must be 108-115mmtor AP 48/53end

90-110mmtor AP38/42.Ifnot,slackenlocknut7

(fig.29) end remove expanding pin out of pin 9.

Turn lork 10 in or out until measure M is

reached. Rep,lace fork 10 end pin 9 info

position, secure with expanding pin 8 end

fighten 'lock nut 7.

Distance N between needle head end knoller

base plots (fig.30)mustbe 170mmon AP38/42

end 175mm on AP 48/53. Otherwise reshape

needle.

Distance 0 between needle end plots spring

(fig. 30) must be between 1-2 mm.

~,

When operating slationary oll dirt end short

baling materia,1has to be removed from under-

neath the needle.

Knotter Beak Tension

Spring tension (fig. 31) should be adjusted to

di,stance P of 23-28 mm tor proper functioning,

if not adjust screw 11accordingly.

fig.32

fig. 28

fig. 29

fig. 30

fig.31

Loading...

Loading...