16

MAINTENANCE

WARNING: Always ensure that the tool is switched off and the plug is removed from the outlet before

making any adjustments or maintenance procedures.

•Any damage to this tool should be repaired and carefully inspected by qualified repair personnel be-

fore use.

•Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will maintain the safety of the power tool.

•Great Lakes Technologies, LLC will not be responsible for any damage or injury caused by unauthor-

ized repair or mishandling of the tool.

POWER CORD MAINTENACE

If the supply cord needs replacing, the manufacturer, the manufacturer’s agent, or an authorized service centre

must carry out the task in order to avoid a safety hazard.

CLEANING

1. Keep the tool’s air vents unclogged and clean at all times.

2. Remove dust and dirt regularly. Cleaning is best done with a soft brush or a rag.

3. Re-lubricate all moving parts at regular intervals.

CAUTION: Do not use cleaning agents to clean the plastic parts of the saw. A mild detergent on a damp cloth is

recommended. Regularly check that all screws are tight. They may vibrate loose over time.

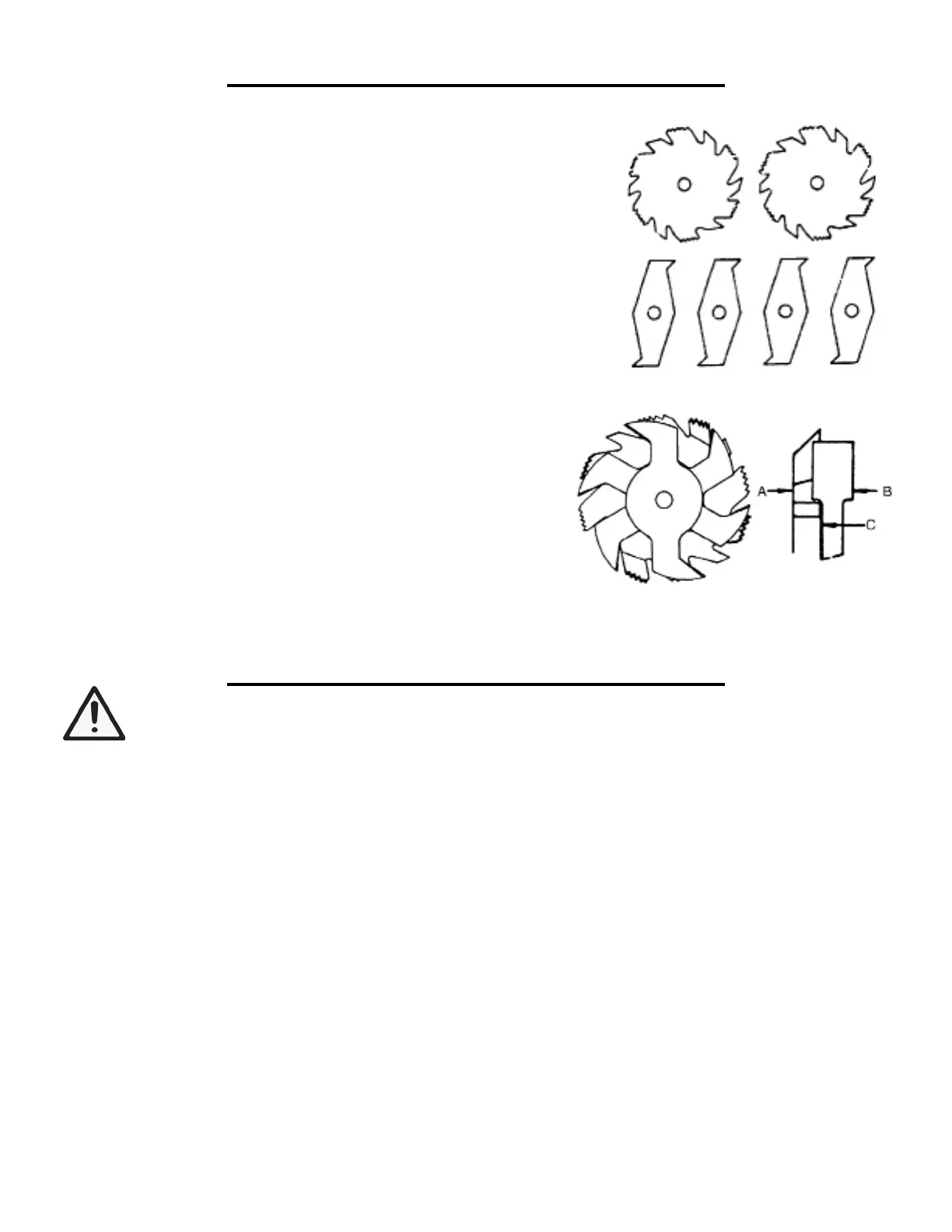

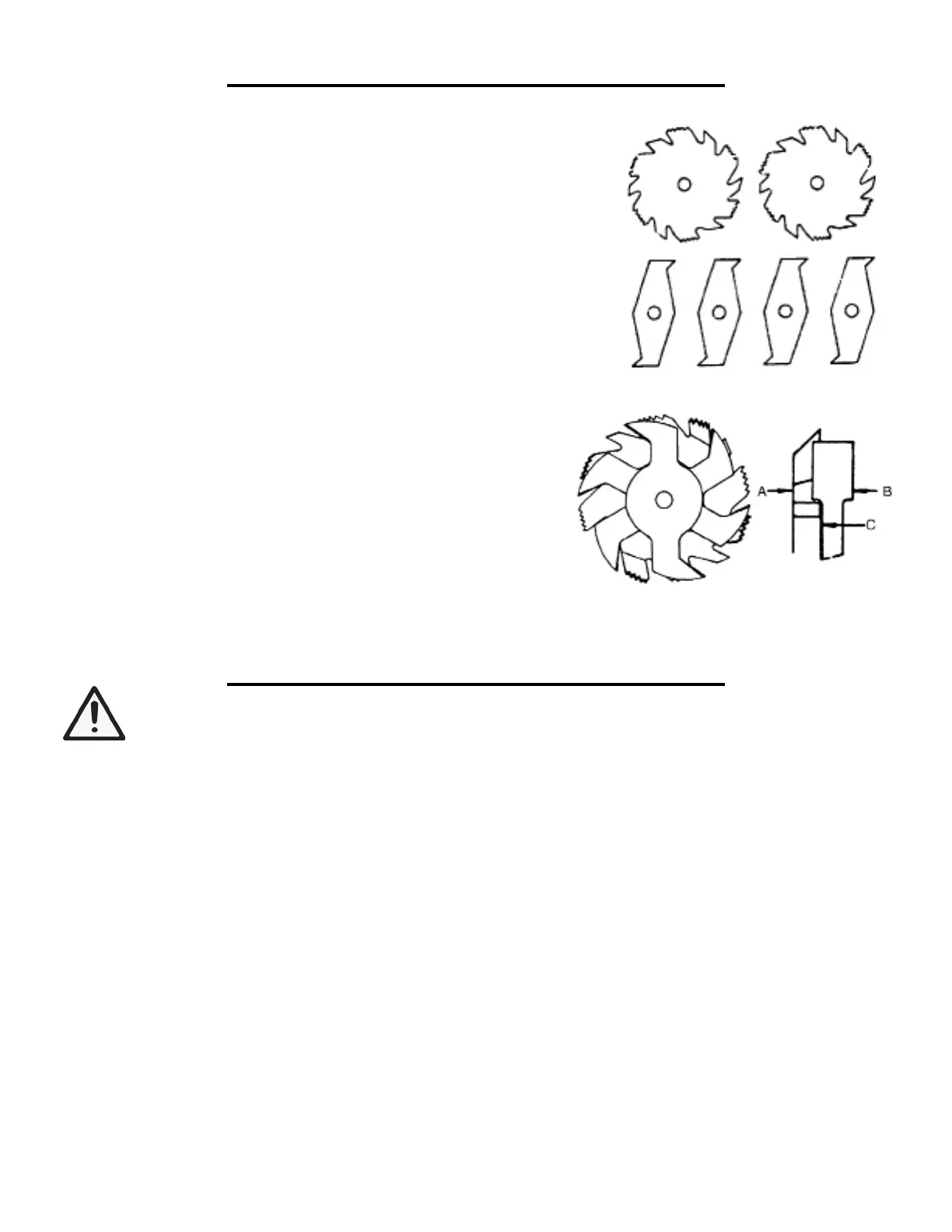

USING A DADO BLADE SET (OPTIONAL) AND DADO

INSERT

Dadoing is cutting a rabbet or a wide groove into the work. Most

dado head sets are made up of two outside blades and four or five

inside cutters, as shown in Fig. 25. Various combination of blades

and cutters are used to cut grooves from 1/8 in. to 13/16 in. for use

in shelving, making joints, tenoning, grooving, ect. The cutters are

heavily swaged and must be arranged so that this heavy portion falls

in the gullet of the outside blades, as shown in Fig. 26. The saw and

cutter overlap is shown in Fig.26, (A) being the outside blade, (B)

being the inside cutter, and (C) being a paper washer which can be

used as needed to control the exact width of groove. A 1/4 in. groove

is cut by using the two outside blades. The teeth of the blades should

be positioned so that the raker on one saw is beside the cutting teeth

on the other saw. The dado head set is assembled to the saw arbor

in the same manner as the saw blade. The blade guard and anti-

kickback finger assemblies can not be used when dadoing operations

and must be removed from the saw. The riving knife must be set in

the “down” position and the included dado table insert must be used

in place of the standard table insert. Never use the dado head in a

bevel position unless you make your own dado insert! Always rein-

stall blade guard and anti-kickback finger assemblies after operation

is complete!

OPERATION

Fig. 25

Fig. 26

Loading...

Loading...