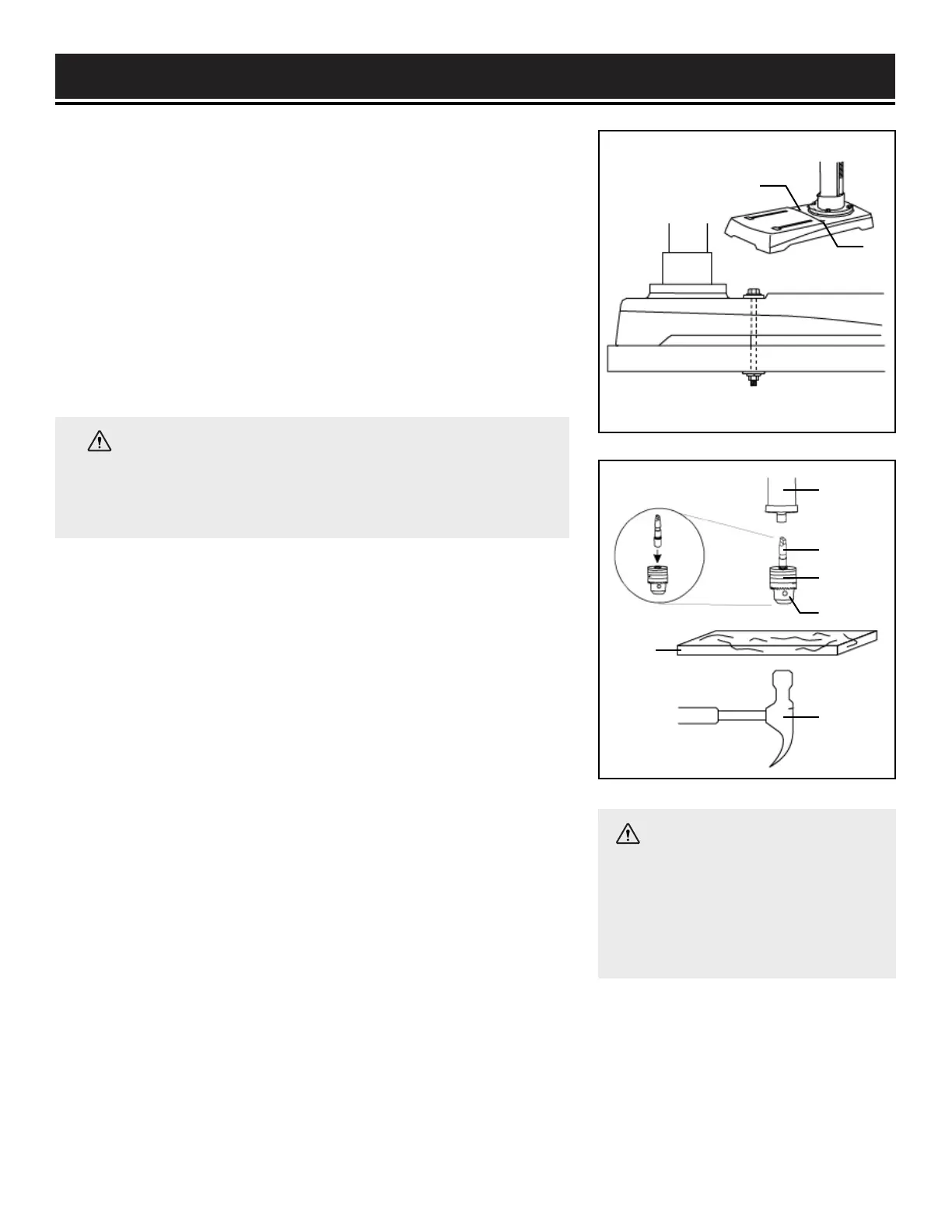

MOUNTING THE DRILL PRESS (FIG. 8)

The drill press must be securely fastened through the mounting

holes (Fig. 8 - 1) to a stand or workbench with heavy-duty

fasteners (not included). This will prevent the drill press from

tipping over, sliding, or walking during operation.

IMPORTANT: If the stand or workbench has a tendency to move

during operation, fasten the workbench securely to the floor.

LED BULB

An LED bulb has been assembled in the socket of the head.

ASSEMBLY & ADJUSTMENTS

13

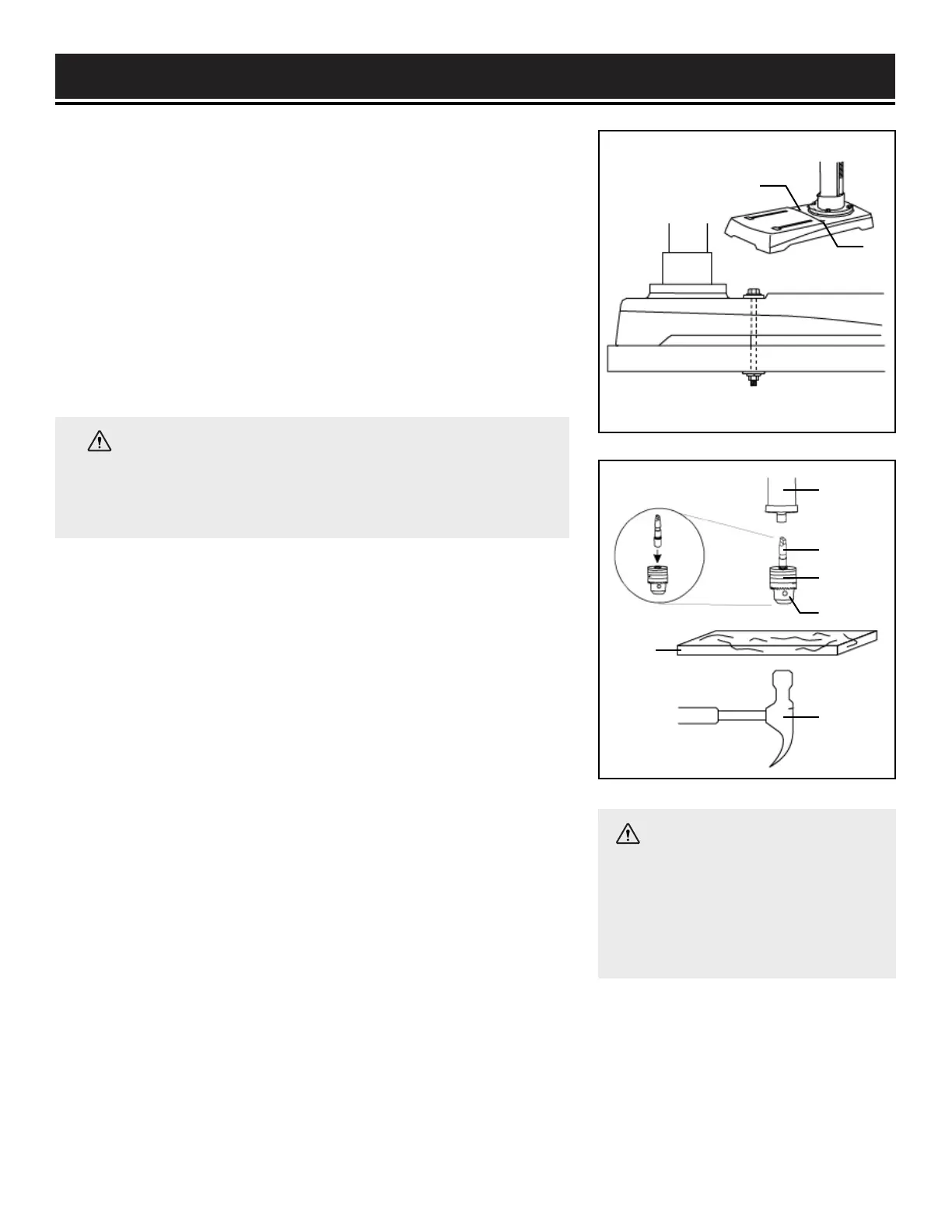

INSTALL THE CHUCK (FIG. 9)

1. Inspect and clean the taper hole in the chuck

(Fig. 9 - 1) and the spindle (Fig. 9 - 2). Remove all grease, coatings,

and particles from the chuck and spindle surfaces

with a clean cloth.

2. Open the chuck jaws (Fig. 9 - 3) by manually turning the chuck

barrel clockwise. Make sure the jaws are completely recessed

inside the chuck.

3. Insert the chuck arbor (Fig. 9 - 4) into the opening at the top of

the chuck.

4. Insert the arbor into the spindle. Rotate it until the tang of the

arbor (the flats on the end) is aligned with the slot in the spindle,

and the chuck and arbor can be pushed upwards. Seat the chuck by

placing a block of wood (Fig. 9 - 5, not included) below the chuck

and firmly tapping the wood once with a hammer. Alternatively,

firmly tap the chuck once with a rubber mallet or dead-blow

hammer (not included).

Fig. 8

Fig. 9

CAUTION: To avoid damaging

the chuck, make sure the jaws

are completely recessed into

the chuck. Do not use a metal

hammer to drive the chuck onto

the arbor or into the spindle.

1

1

1

2

3

4

5

6

WARNING: To reduce risk of fire, DO NOT use a light

bulb greater than 40 watts. When changing the light bulb,

always check that the power switch is in the OFF position

and the plug is disconnected from its power source.

5. If the chuck or arbor fail to seat properly, they may not be clean enough. Remove them and thoroughly

clean the mating surfaces, then try again. Ensure all dust, debris, and liquids are removed from the surfaces,

and that neither surface is damaged.

Loading...

Loading...