MAINTENANCE

Refer to Recommended Maintenance Schedule in Fig. 21 for maintaining the spark plug.

The spark plug is important for proper engine operation. Check the spark plug regularly to maintain proper

engine operation. A good spark plug should be intact, free of deposits, and properly gapped.

SPARK PLUG MAINTENANCE

To inspect or replace the spark plug:

1. Using a Phillips-head screwdriver (not included), unscrew the

top two screws (Fig. 23 - 1) and remove the service panel on the

opposite side of the recoil starter.

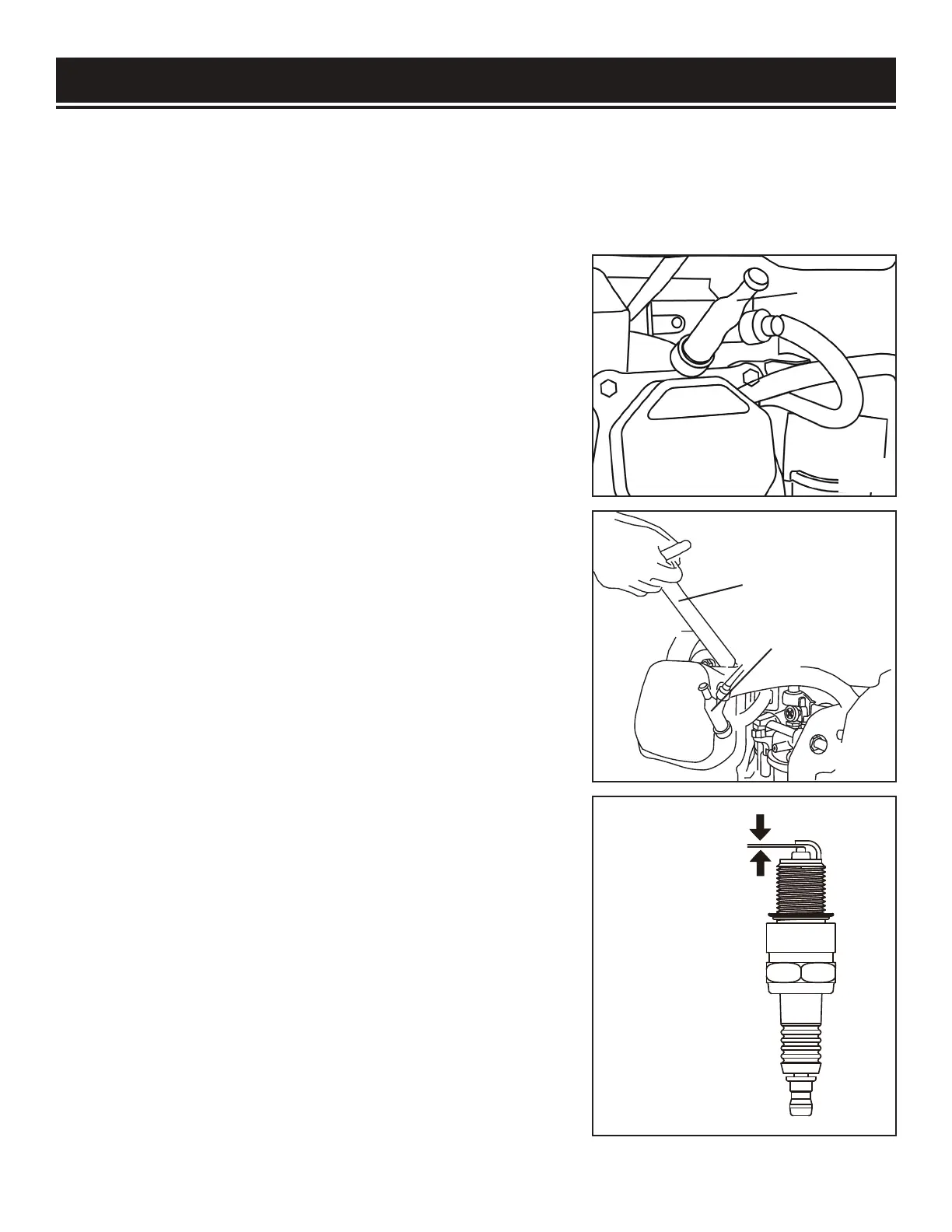

2. Gently pull on the spark plug boot (Fig. 27) to remove it. Be

careful not to tear any insulation or wire.

3. Use the included spark plug wrench to unscrew and then care-

fully remove the spark plug from the engine (Fig. 28). TIP: There

is limited space for the wrench to turn. Use both rows of holes in

the spark plug wrench to gain leverage to loosen the plug.

4. Visually inspect the spark plug. If it is cracked or chipped, or if

the electrodes are worn or burned, discard it and replace with a

new spark plug.

We recommend replacing with a NGK BPR6ES/Torch F6RTC

spark plug (part no. 56310i-0104), available for purchase at

wenproducts.com.

5. If re-using the spark plug, use a wire brush to clean any dirt

from around the spark plug base, then re-gap the spark plug.

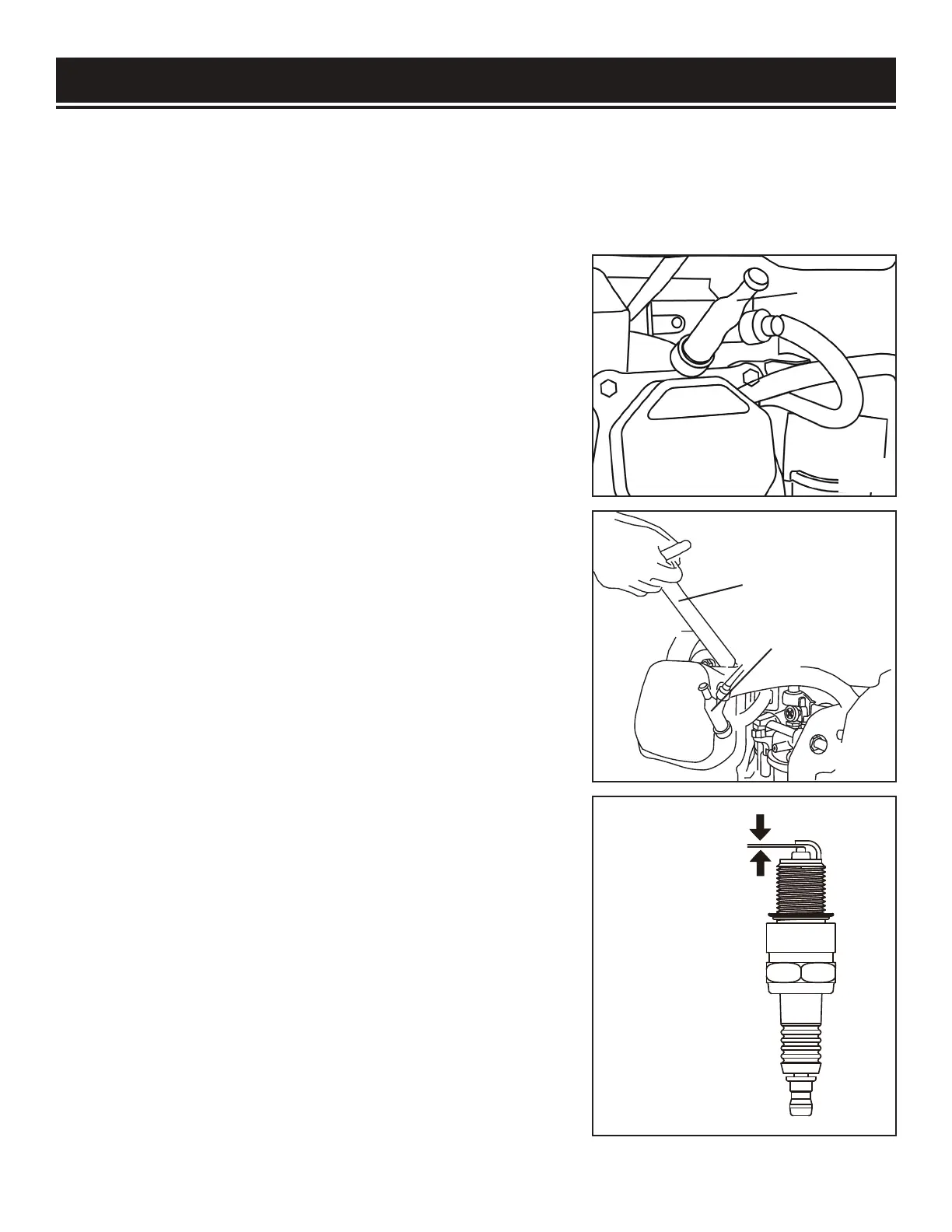

6. Measure the plug gap with a spark plug gap gauge. The gap

should be 0.7 - 0.8 mm (0.028 - 0.031 in) (Fig. 29). Carefully

adjust the gap if necessary.

7. Screw the spark plug back into the spark plug hole using the

spark plug wrench. Do not over-tighten spark plug. Recommended

tightening of spark plug is ½ to ¾ of a turn (15 ft-lb torque/20.33

Nm) after spark plug gasket contacts spark plug hole.

8. Reinstall the spark plug boot, spark plug rubber cover, and ser-

vice panel.

Fig. 27

Plug Wrench

Spark Plug Boot

Spark Plug

Boot

Cylinder

Assembly

Fig. 28

Fig. 29

0.7 - 0.8 mm

28

Loading...

Loading...