OPERATOR’S)MANUAL))

Page!12!)

!

!

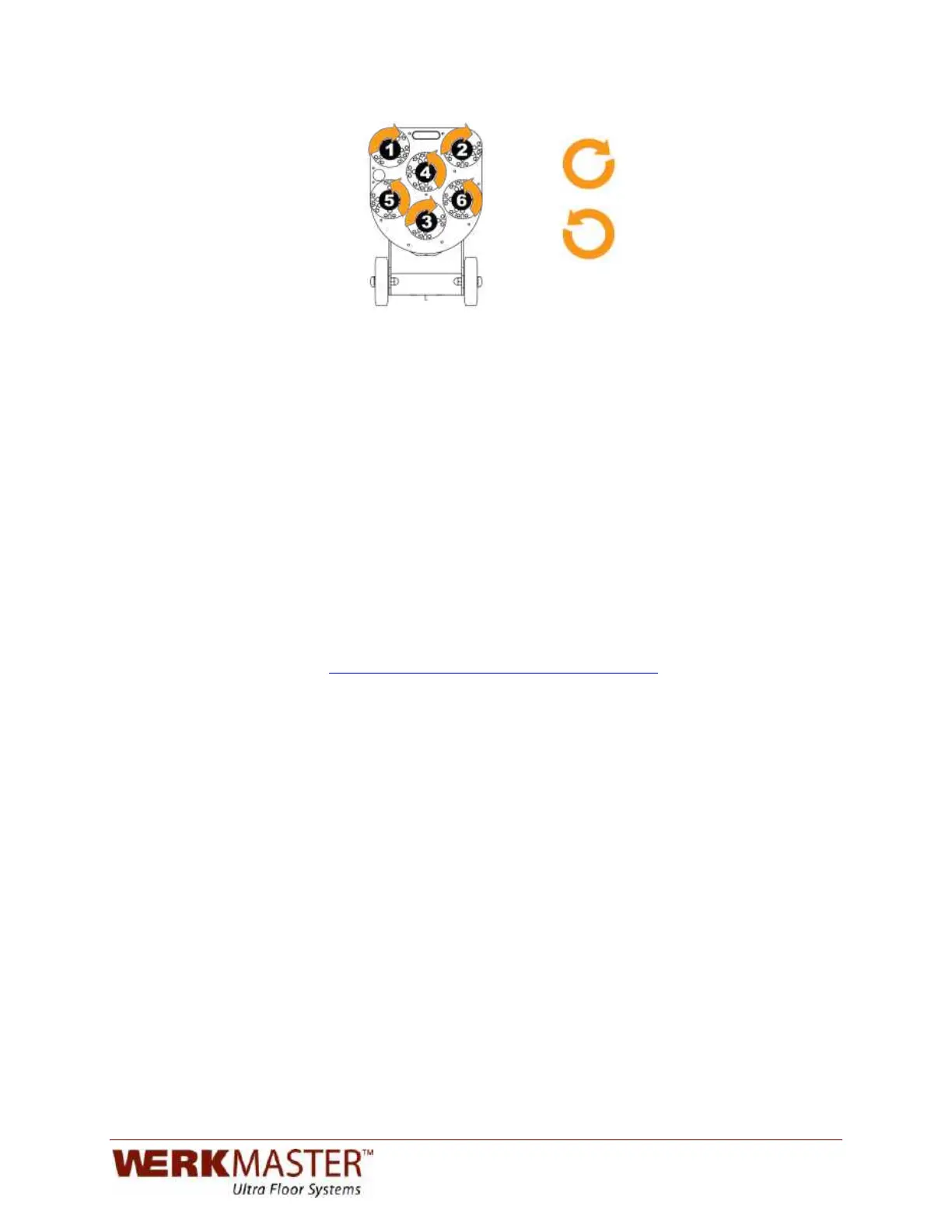

Discs 1, 2, and 3 rotate

clockwise CW

)

)

Discs 4, 5, and 6 rotate

counter-clockwise CCW

)

)

)

!!!!!!!!Bottom!of!WerkMaster!with!numbered!tooling!plates!and!clockwise!and!counterclockwise!labeling.!

!

!

To replace a broken shear pin:

1. Remove the Plug ‘N Go plate (D) (Fig 4) from the pad driver (F). Before

replacing the shear pin apply a generous amount of permanent red thread

locker (Loctite 266) on the screw and into the hole.

2. Hold the shear pin securely and firmly tighten the screw until the shear pin

cannot spin. Replace the Plug ‘N Go plate.

To replace a bent shear pin:

1. Remove the Plug ‘N Go plate (D). Remove the bent shear pin by hitting with a

hammer. Before replacing the shear pin apply a generous amount of

permanent red thread locker (Loctite 266) on the screw and into the hole;

tighten.

2. Hold the shear pin securely and firmly tighten the screw until the shear pin

cannot spin. Replace the Plug ‘N Go plate.

SEE: How To Series: Replacing a Shear Pin

at http://www.werkmaster.com/replacing-a-shear-pin/

Loading...

Loading...