ALTERNATOR/REGULATOR

SERVICE

The

voltage

reading

for a properly operating alternator

should be between 13.5 and 14.5 volts.

If your alternator is

over-

or

undercharging, have

it

repaired at a reliable service

shop,

or

continue

with

the following tests.

NOTE:

Before removing the alternator for

repair,

use your

voltmeter to ensure that

I2

volts

DC

excitation is preselll at

the R (£XC) terminal

if

the previous tesi showed only battery

voltage at the B output terminal.

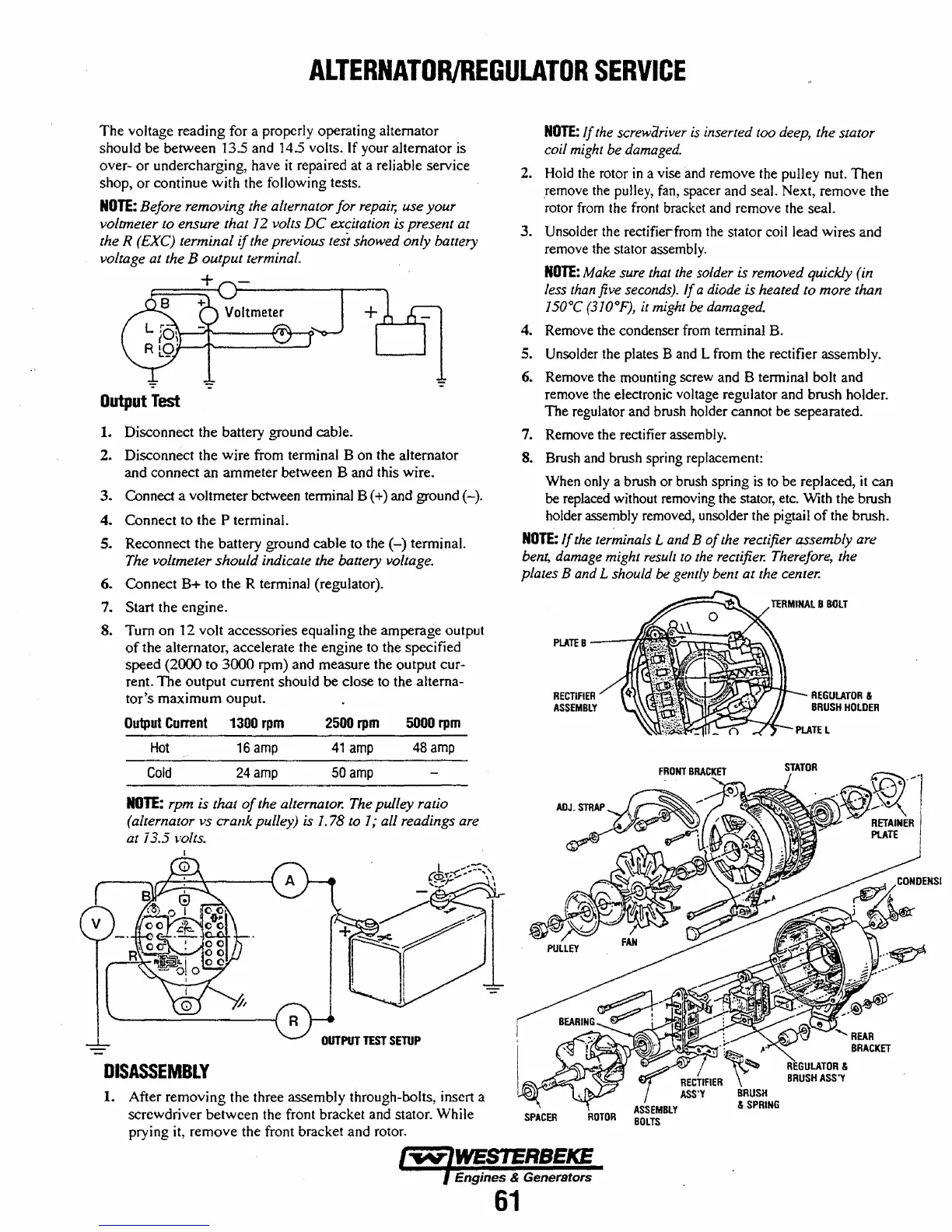

+

Output

Test

1. Disconnect the battery ground cable.

2. Disconnect the

wire

from terminal B on the alternator

and

connect

an

ammeter

between B and this wire.

3.

Connect a voltmeter between terminal B (+) and ground

(-).

4.

Connect to the P terminal.

5.

Reconnect the battery ground

cable

to the

(-)

tenninal.

The voltmeter

should

indicate the battery voltage.

6.

Connect

B+

to the R terminal (regulator).

7.

Start the engine.

S.

Tum

on

12

volt

accessories equaling the

amperage

output

of

the alternator, accelerate the engine to the specified

speed

(2000

to

3000

rpm) and measure the output cur-

rent.

The

output

current should

be

close to the alterna-

tor's

maximum

ouput.

Output

Current 1300

rpm

2500

rpm

5000

rpm

Hot

16

amp

41

amp

48

amp

Cold

24

amp

50

amp

NOTE:

rpm is thaI

of

the alternator. The pulley ratio

(alternator vs crank pulley)

is

1.78 to 1; all readings are

at

j 3.5 liolts.

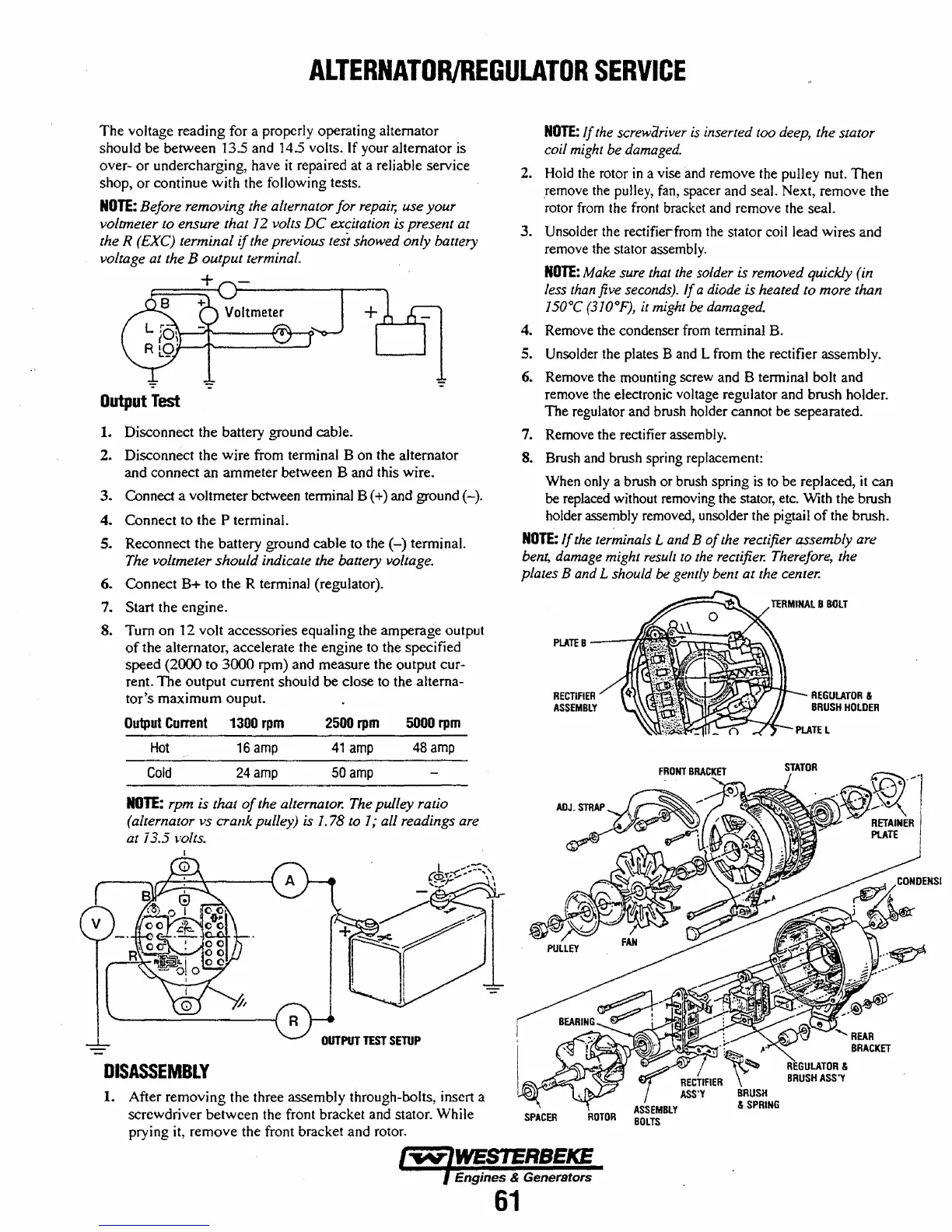

OUTPUT

TEST

SETUP

DISASSEMBLY

1.

After

removing

the three assembly through-bolts, insert a

screwdriver

between

the front bracket and stator. While

prying it,

remove

the front bracket and rotor.

NOTE:

If

the screwariver

is

inserted too deep, the slOtor

coil might be damaged.

2. Hold the rotor

in

a vise and remove the pulley nut.

Then

remove the pulley, fan, spacer and seal. Next, remove the

rotor from the front bracket and remove the seal.

3.

Unsolder the rectifierfrom the stator coil lead wires and

remove the stator assembly.

NOTE:

Make sure that

the

solder is removed quickly (in

less

than

five seconds).

If

a diode is heated to more than

I50

a

C (310°F), it might

be

damaged.

4. Remove the condenser from terminal B.

5. Unsolder the plates

Band

L from the rectifier assembly.

6. Remove the mounting screw and B terminal bolt and

remove the electronic voltage regulator and brush holder.

The

regulator and brush holder cannot be sepearated.

7. Remove the rectifier assembly.

S. Brush and brush spring replacement:

When only a brush or brush spring is to be replaced,

it

can

be

replaced without removing the stator, etc. With the brush

holder assembly removed, unsolder the pigtail

of

the brush.

NOTE:

If

the terminals

Land

B

of

the rectifier assembly are

bent,

damage might result to the rectifier. Therefore, the

plates

Band

L should

be

gently bent

at

the center.

RECTIFIER

ASSEMBLY

SPACER

ROTOR

TERMINAL

B

BOLT

REGULATOR

&

BRUSH

HOLDER

STATOR

........

REAR

BRACKET

Engines & Generators

61

Loading...

Loading...