Kunststoffschweißtechnik

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

25.06.12 Working instructions WIDOS 4001 Page 15 of 59

3. Description of process

B a s i c a l l y , t h e i n t e r n a t i o n a l a n d n a t i o n a l p r o c e s s g u i d e l i n e s a r e t o

b e f o l l o w e d !

At first, the clamping tools are fixed on the machine slide.

For the fabrication of angles and bows, the clamping tools can be turned on both sides.

The plastic pipes are clamped by means of the clamping tools.

If necessary, stabilize the pipes by means of roller stands or pipe supports (for bows, a

supporting angle is existing).

Then the front sides of the pipes are planed parallel by means of the planer and the

misalignment of the pipes is checked.

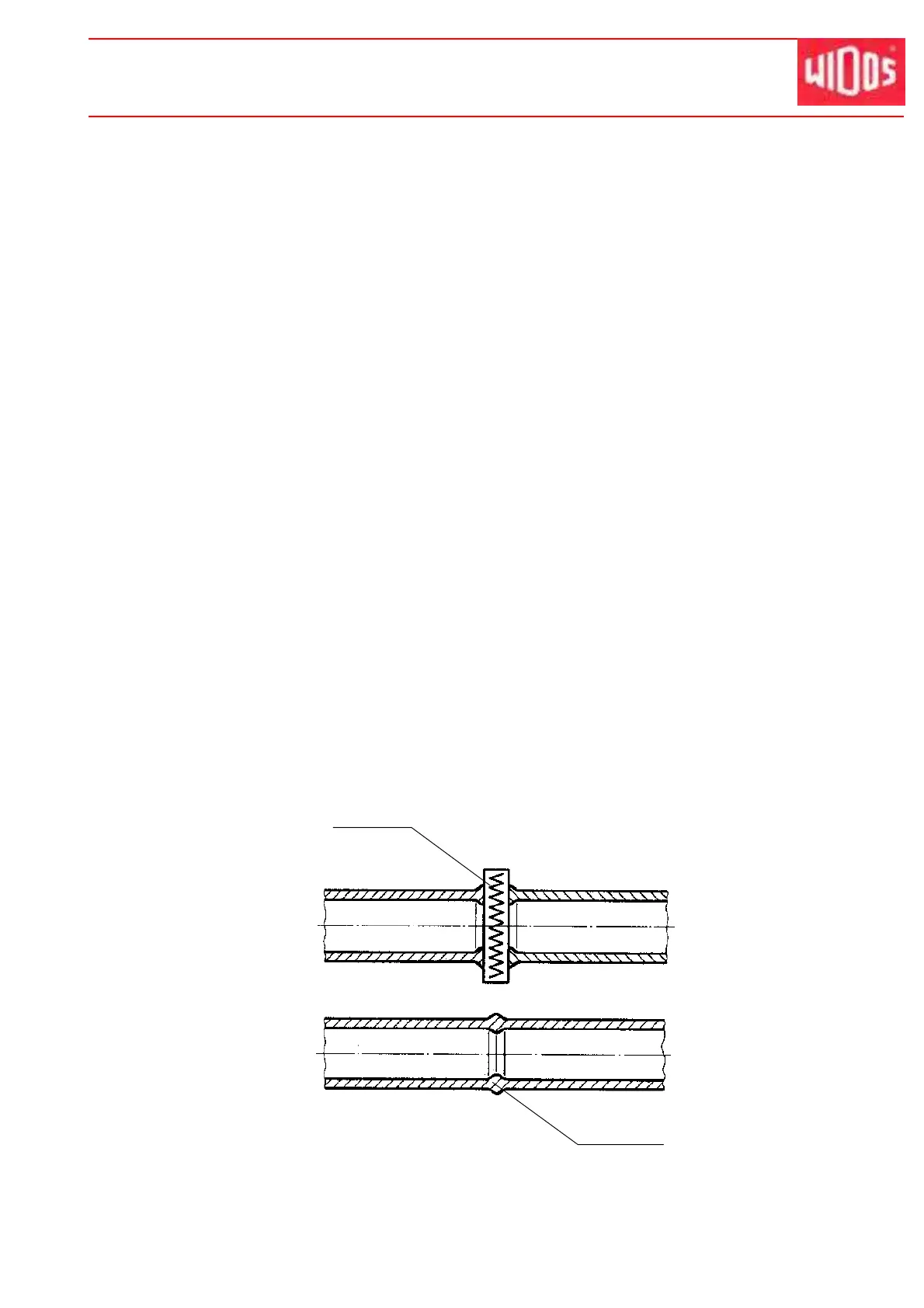

Now the heating element is swivelled in and the pipes are pressed against the heating element

under defined adjusting pressure. This process is called "adjusting".

After the prescribed bead height being reached, pressure is reduced, heat up time begins.

The function of this time is to heat up the pipe ends.

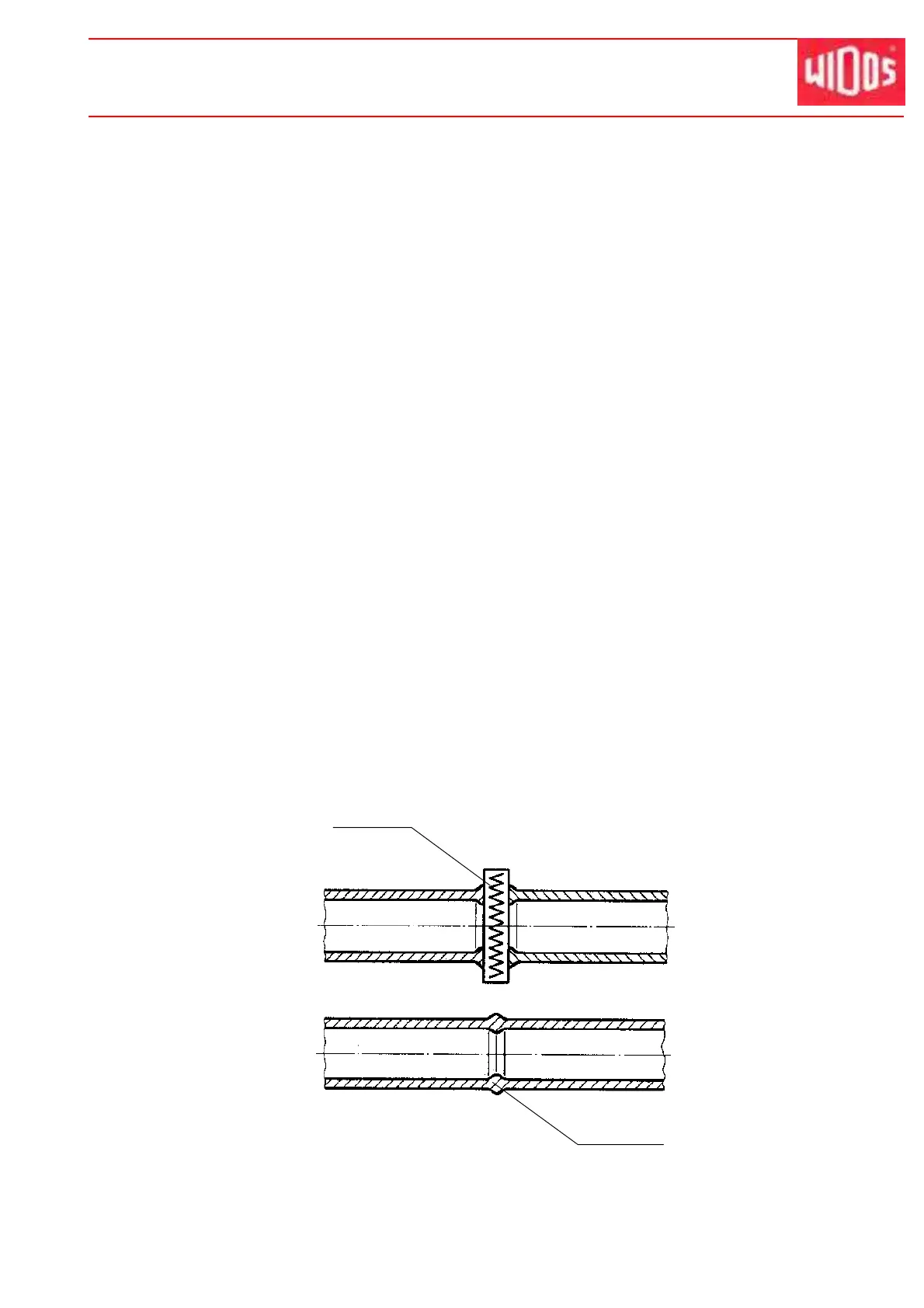

After expiration of the heat up time, the slides are opened, the heating element is swivelled out

quickly and the pipes are closed again hydraulically.

The time gap from the removal of the heating element to joining the pipes is called change

over time.

The pipes are joined under prescribed welding pressure and then cool down under pressure

(cooling time).

The welded joint can be unclamped, the welding process is finished.

Heating element heats

up the pipes up to

welding temperature

Finished welding with

inside and outside bead

Loading...

Loading...