en Installation

22 WILO SE 2020-05

M

3~

M

1~

T1

1 3 5 13 A1

2 4 6 14 A2

T2 T3

L1 L2 L3 NO

PE

2

4

Fig.8: Pump connection

2 Motor contactor

4 Earth terminal

Insert the connection cables laid by the customer through the threaded cable glands

and secure. Connect the wires to the contactor as per the connection diagram:

Control MS-L.../MS-L...-O

ƒ Terminal assignment 1~230V

L = 4/T2, N = 6/T3, PE = earth terminal

ƒ Terminal assignment 3~400V

U = 2/T1, V = 4/T2, W = 6/T3, PE = earth terminal

bn = 2/T1, bk = 4/T2, gy = 6/T3, PE = earth terminal

Control MS-L...-LS

ƒ Terminal assignment 1~230V

L = 4/T2, N = 2/T1, PE = earth terminal

ƒ Terminal assignment 3~400V

U = 2/T1, V = 4/T2, W = 6/T3, PE = earth terminal

bn = 2/T1, bk = 4/T2, gy = 6/T3, PE = earth terminal

6.5.5 Adjust motor current monitoring

The electronic motor current monitoring monitors the rated current of the connected

pump. Set rated current according to rating plate:

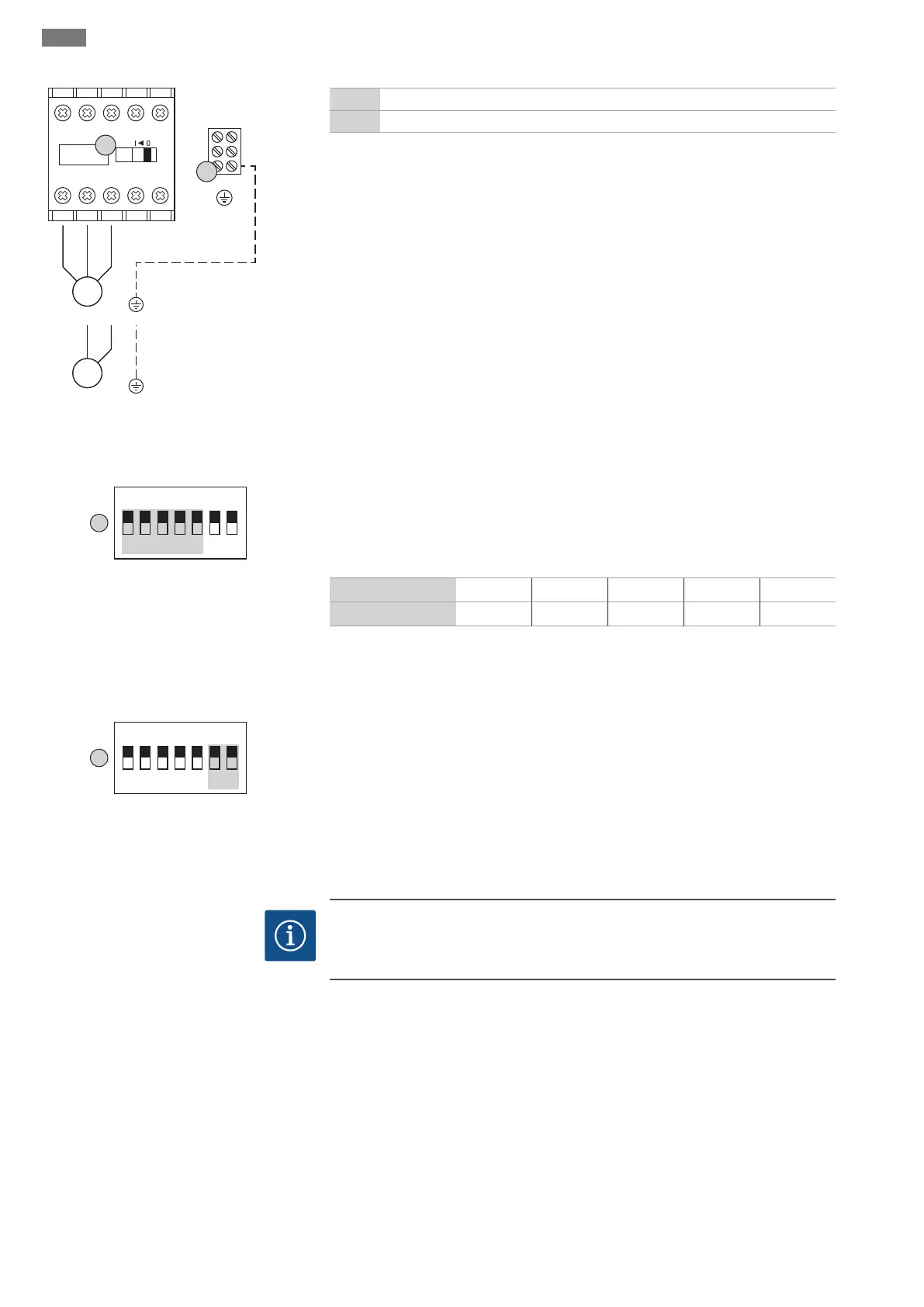

Fig.9: DIP switch1: Adjust motor current mon-

itoring

ƒ Set rated current via DIPs1-5 on DIP switch1.

ƒ Minimum rated current: 1.5A. All DIPs are in the “OFF” position.

ƒ The current value is increased by the value of the respective DIP by activating the in-

dividual DIPs (“ON” position).

ƒ Max. rated current: 12A.

DIP

1 2 3 4 5

Current value

0.5A 1.0A 2.0A 3.0A 4.0A

Example: required rated current 7.5A

1.5A + 2.0A (DIP3) + 4.0A (DIP5) = 7.5A

6.5.6 Switch on pumps (only Control

MS-L2...)

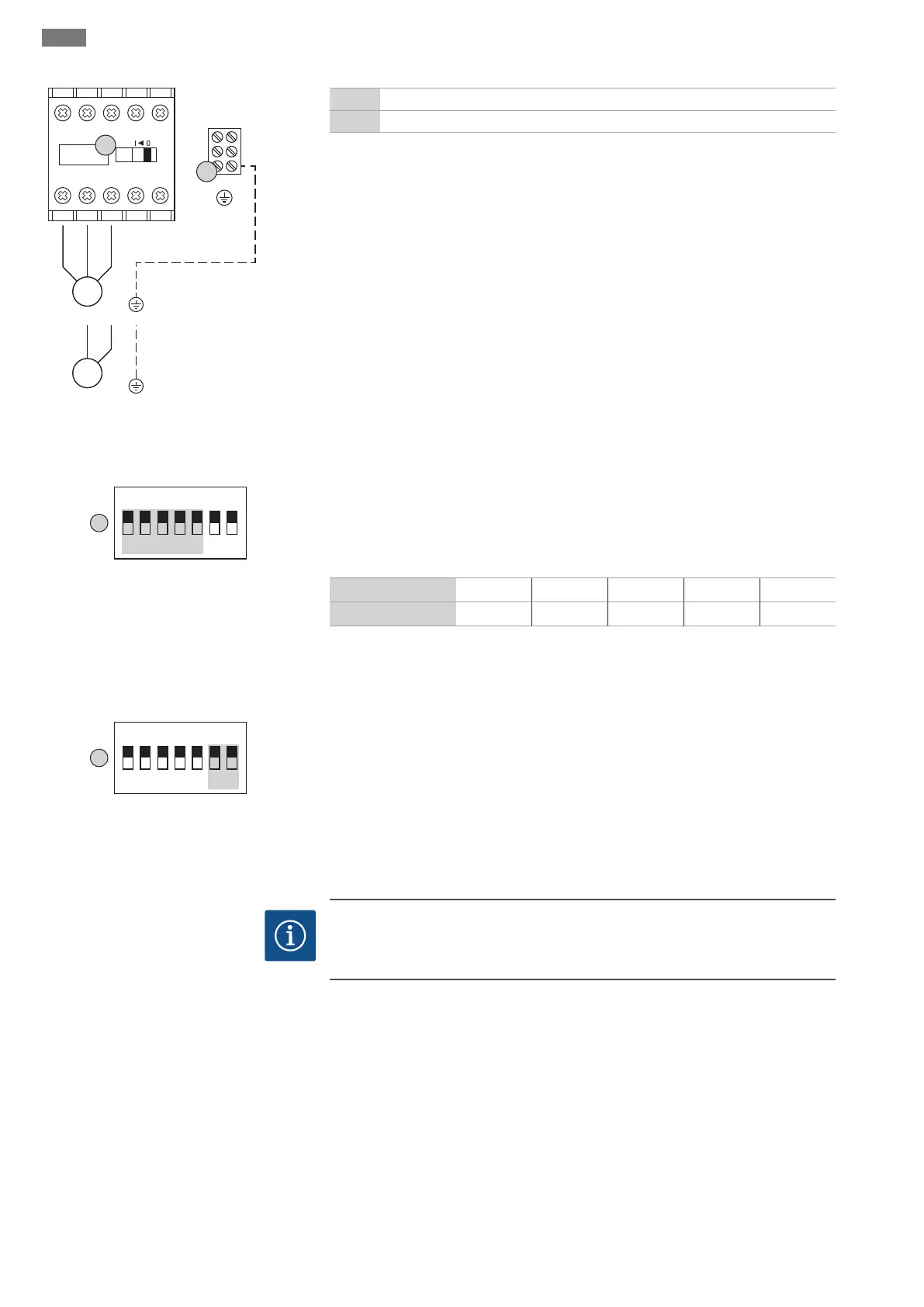

The connected pumps are switched on via DIPs6 and 7 on DIP switch2:

Fig.10: DIP switch2: Switch on pumps

ƒ The factory setting for both DIPs is “OFF”. Level control dependent activation of the

pumps is not possible.

ƒ Switch on pump 1: Set DIP6 to “ON”.

ƒ Switch on pump 2: Set DIP7 to “ON”.

6.5.7 Connection, thermal motor mon-

itoring

NOTICE

Do not apply external voltage!

An external voltage which is applied destroys the component.

Loading...

Loading...