30 WILOSE04/2014V05DINA4

English INSTALLATION

5.3. Installation

DANGER of falling!

When installing the pump and its accessories,

work is sometimes performed directly at the

edge of the basin or sump. Carelessness or

wearing inappropriate clothing could result

in a fall. There is a risk of fatal injury! Take all

necessary safety precautions to prevent this.

The following information should be taken into

considerationwheninstallingthepump:

• Thisworkmustbecarriedoutbyaqualied

person and electrical work must be carried out by

an electrician.

• Thecollectortankmustbeclean,freeofcoarse

solids,dry,frost-freeand,ifnecessary,de-

contaminated. It must also be suitable for the

particular pump.

• Whenworkinginsumps,asecondpersonmust

be present for safety reasons. If there is a risk of

poisonousorasphyxiatinggasesforming,the

necessary precautions must be taken.

• Depending on the ambient conditions in opera-

tion,theunitplannermustselectthesumpsize

and motor cooling time accordingly.

• Ensurethatliftingequipmentcanbetted

withoutanytrouble,sincethisisrequiredfor

assembly and removal of the pump. It must be

possible to reach the pump safely in its operating

and storage locations using the lifting equip-

ment.Themachinemustbepositionedonarm

bearingsurface.Fortransportingthepump,the

load-carrying equipment must be secured to the

liftingeyeletsprovided.Whenusingchains,they

must be connected with a shackle to the lifting

eyeletsorthecarryinghandle.Liftinggearmust

be technically approved.

• Power supply cables must be laid out in such

a way that safe operation and trouble-free

assembly/dismantling are possible at all times.

The pump must never be carried or dragged by

thepowersupplycable.Checkwhetherthecable

present is long enough for its cross-section and

its installation type.

• Whenusingswitchgears,thecorresponding

protectionclassmustbeobserved.Ingeneral,

switchgears must be installed outside potentially

explosive areas in such a way that they are pro-

tectedfromooding.

• Structural components and foundations must

besufcientlystabletoallowtheproducttobe

anchored securely and functionally. The operator

or the supplier is responsible for the provision of

the foundations and their suitability in terms of

dimensions,stabilityandstrength.

• If the motor housing is to be taken out of the

uidduringoperation,theoperatingmodefor

non-immersed operation should be followed.

To keep dry motors sufciently cooled in S3

mode, they must be ooded completely before

being switched back on if the motor has been

taken out of the uid!

• Never let the pump run dry. The water level must

neverfallbelowtheminimum.Therefore,we

recommend installing a level control system or a

dry-running protection system where there are

great variations in the level.

• Useguideanddeectorplatesfortheuidintake.

Ifthewaterjetreachesthesurfaceofthewater,

airwillbeintroducedintotheuid,whichcan

accumulate in the pipe system. This can result in

inadmissible operating conditions and to deacti-

vation of the entire system.

• Checkthattheavailableconsultingdocumen-

tation(installationplans,layoutofthecollector

tank,intakeratios)iscompleteandcorrect.

• Pleaseobserveallregulations,rulesandlegal

requirements for working with and underneath

heavy suspended loads. Wear appropriate protec-

tive clothing/equipment.

• Please also observe the applicable national acci-

dent prevention regulations and trade association

safety provisions.

5.3.1. Maintenance work

Afterastorageperiodofmorethan6months,the

following maintenance work must be carried out

beforeinstallation:

• Rotate impeller

• Checkoillevelinthesealingchamber

Rotate impeller

1. Positionthepumphorizontallyonarmsurface.

Make sure that the pump cannot fall over and/

or slip.

2. Carefullyandslowlyreachintothehydraulics

housing from below and rotate the impeller.

BEWARE of sharp edges!

Sharp edges can form on the impeller and

hydraulic opening. There is a risk of injury!

Wear the necessary protective clothing, such

as protective gloves.

Check oil level in sealing chamber

The sealing chamber has a hole for draining and

llingthechamber.

1. Positionthepumphorizontallyonarmsurface

with the screw plug facing upward.

Make sure that the pump cannot fall over and/

or slip.

2. Unscrewthescrewplug(seeFig.4).

3. The oil should reach up to about 1 cm below the

hole for the screw plug.

4. Ifthereisnotenoughoilinthesealingchamber,

topitup.Todoso,followtheinstructionsunder

“Oilchange”inthe“Maintenanceandrepair”

chapter.

5. Cleanthescrewplug,replacethejointring,if

necessary,andscrewitbackin.

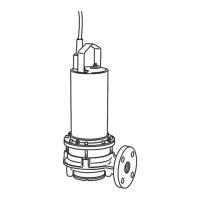

5.3.2. Portable wet well installation

The pump can be positioned anywhere in the

operating space using the built-in pump foot.

Loading...

Loading...