28 WILOSE04/2014V05DINA4

English TRANSPORTANDSTORAGE

ing chamber between the mechanical shaft seals

islledwithecologicallysafemedicinalwhiteoil.

3.2.5. Materials

• Motorhousing:EN-GJL-250

• Hydraulichousing:EN-GJL-250

• Impeller:EN-GJL-250

• Shaftend:1.4021

• Staticgaskets:HNBR

• Seal

• Onpumpside:SiC/SiC

• Onmotorside:Carbon/steatite

3.3. Operating modes

3.3.1. Operating mode S1 (permanent operation)

The pump can operate continuously at the rated

load without exceeding the permissible temper-

ature.

3.3.2. Operating mode S3 (intermittent operation)

Thisoperatingmodedenesacombination

of periods of operation and standstill. With S3

operation,thevaluesgivenarealwayscalculated

basedonaperiodof10minutes.

• S325%

Operatingtime25%of10min=2.5min/stand-

stilltime75%of10min=7.5min

3.4. Technical data

General data

Mainsconnection[U/f]: 3~400V/50Hz

Voltagetolerance: ±10%

Powerconsumption[P

1

]: See rating plate

Ratedpower[P

2

]: See rating plate

Ratedcurrent[I]: See rating plate

Startingcurrent[I

ST

]: See rating plate

Maximumdeliveryhead[H]: See rating plate

Maximumvolumeow[Q]: See rating plate

Activationtype[AT]: direct

Protectionclass: IP68

Insulationclass[Cl.]: F

Speed[n]: See rating plate

Max.immersiondepth: 7m

Suctionconnection: -

Pressureconnection: G1¼(DN32)

Freeballpassage: 9mm

Weight[M]: 39kg

Explosionprotection: -

Operating modes

Submerged[OT

S

]: S1

Non-immersed[OT

E

]: S325%

Switching frequency

Recommended: 20/h

Maximum: 50/h

Cable

Type: TGSH-J

Size: 7G1.5

Length: 10 m

Fluid temperature [T]

Immersed: 3…95°C(37...203°F)

Non-immersed: 3…75°C(37...167°F)

3.5. Type key

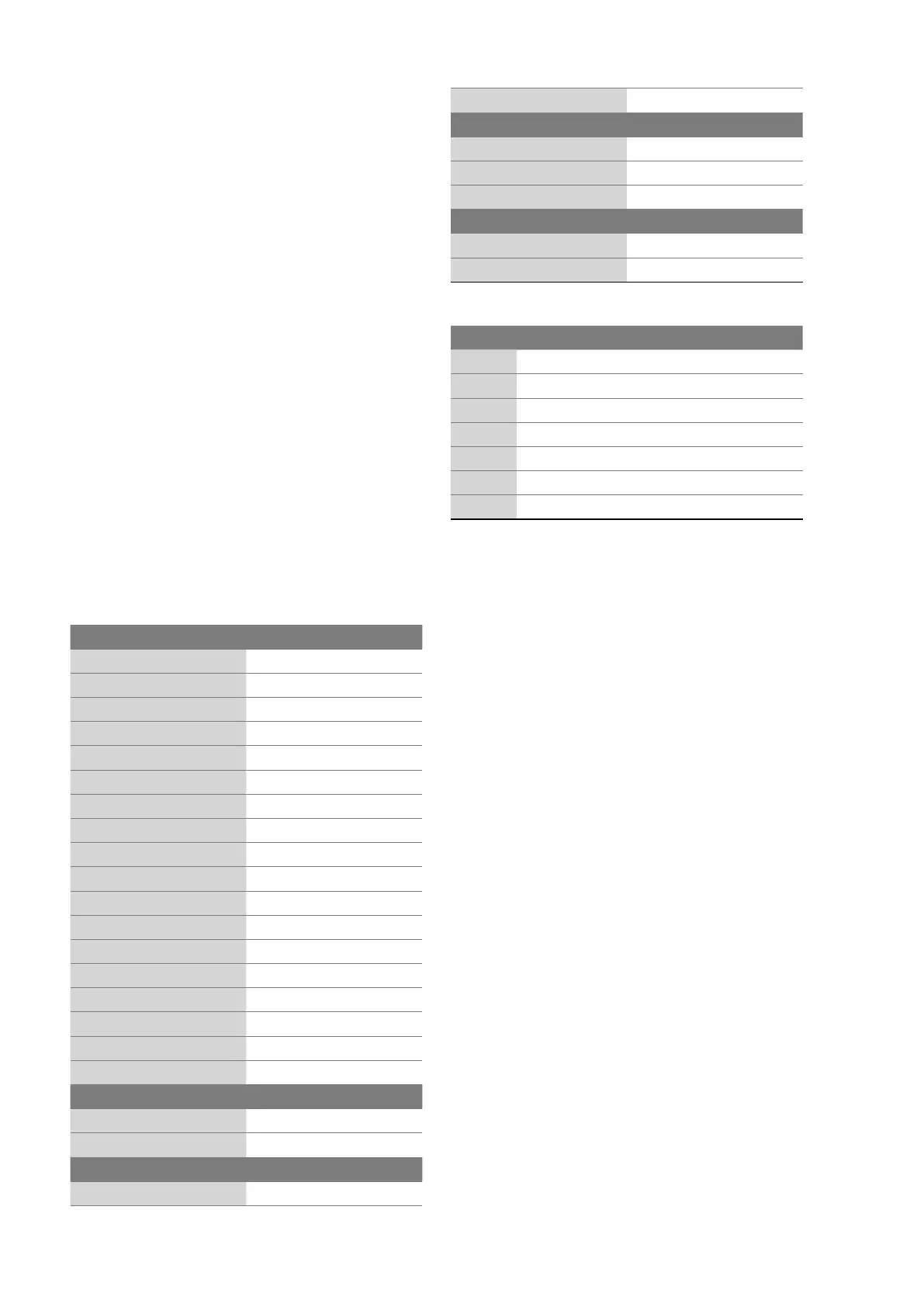

Example: Wilo-Drain TMT 32M113/7.5Ci

TM

Tauchmotorpumpe(submersiblepump)

T

Pumping of wastewater

32

PressureconnectionG1¼(DN32)

M

Half-open multi-channel impeller

113

Impeller diameter in mm

7.5

/10=ratedpowerP

2

in kW

Ci

Materialversion:Castiron

3.6. Scope of delivery

• Pumpwith10mcableandbarecableend

• Installation and operating instructions

3.7. Accessories

• 90°pipeelbow

• Levelcontroldevices

• Fixingaccessoriesandchains

• Switchgears,relaysandplugs

4. Transport and storage

4.1. Delivery

Ondelivery,checkimmediatelythattheship-

ment is complete and undamaged. If any parts

aredamagedormissing,thetransportcompany

orthemanufacturermustbenotiedontheday

ofdelivery.Claimsmadeafterthisdatecannotbe

recognised. Damage to parts must be noted on

the freight documentation.

4.2. Transport

Onlytheappropriateandapprovedfastening

devices,transportationandliftingequipmentmay

beused.Thesemusthavesufcientload-bearing

capacity to ensure that the pump can be trans-

ported safely. If chains are used they must be

secured against slipping.

Thepersonnelmustbequaliedforthetasksand

must follow all applicable national safety regula-

tions during the work.

The pump is delivered by the manufacturer or

shipping agency in suitable packaging. This nor-

mally precludes the possibility of damage occur-

ring during transport and storage. The packaging

should be stored in a safe place for reuse if the

product is frequently used at different locations.

Loading...

Loading...