Installation and operating instructions Wilo-Drain TMT 32M 31

INSTALLATION English

Eitherapressurehoseoranexistingdischarge

pipeline is connected to the pressure side.

Ifthemotoremergesduringoperation,the

following operating parameters must be strictly

observed:

• The max. uid temperature and ambient tem-

perature is 75°C.

• Non-immersedoperatingmode:S325%

BEWARE of burns!

The housing parts can heat up to above

100°C. There is a risk of burns! After switch-

ing it off, let the pump cool down to ambient

temperature.

Discharge pipeline connection

NOTE

The pump is only held in place here by the pip-

ing. All vibrations and torques are transferred to

the pipe system!

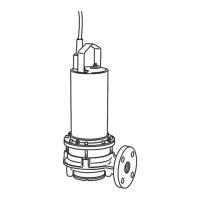

Fig. 2.: Stationary installation

1 Pump 4 Impact protection plate

2 Discharge pipeline 5 Inlet

3 Non-return valve

6a

Min. water level for im-

mersed operation

6b

Min. water level for

non-immersed operation

Work steps

1. Preparingpumps:about1h

• Connectthepipeelbowtothepressureport

usingthethreadedange/angeconnection.

2. Installingthepump:about1-2h

• Oncethepipeelbowhasbeenconnected,posi-

tion the pump at the pressure pipe. If neces-

sary,secureliftingequipmenttothepumpwith

ashackle,liftthepumpandthenlowertothe

intendedlocation(sump,pit).

• Screw the pipe elbow onto the existing dis-

charge pipeline.

• Route the power supply cable in such a way

that it cannot be damaged.

• Have the electrical connections made by a

qualiedelectrician.

3. Commissioningthepump:about1-3h

• Asdescribedinthe“Commissioning”section

Connecting a pressure hose

RISK of pressure hose becoming separated!

Uncontrolled separation or movement of the

pressure hose can result in injuries. Secure the

pressure hose appropriately. Prevent buckling

of the pressure hose.

Work steps

1. Preparingpumps:about1h

• Fitthepipeelbowtothepressureconnection

using the hose connection.

• Fastenthepressurehosetothepipeelbow

with a hose clip.

2. Installingthepump:about1-2h

• Position pump in installation location. If neces-

sary,secureliftingequipmenttothepumpwith

ashackle,liftthepumpandthenlowertothe

intendedlocation(sump,pit).

• Checkthatthepumpisverticalandonasolid

bearing surface.

Avoid sinking.

• Route the power supply cable so it cannot be

damaged.

• Have the electrical connections made by a

qualiedelectrician.

• Route the pressure hose so that it is not

damaged and fasten it at certain points (e.g.

outow).

3. Commissioningthepump:about1-3h

• Asdescribedinthe“Commissioning”section

5.3.3. Level control

Filllevelscanbedeterminedusingthelevel

controlsystem,meaningthepumpisswitchedon

andoffautomatically.Thelllevelcanberecord-

edusingoatswitches,pressureandultrasound

measurements or electrodes.

Notethefollowinginformation:

• Whenusingoatswitches,ensurethattheycan

move freely in the operating area!

• The water level must not fall below the minimum!

• The maximum switching frequency may not be

exceeded!

• Ifthelllevelsuctuatestrongly,thenalevel

control should be made on two test points as

standard. This means larger differential gaps are

reached.

Installation

Forcorrectinstallation,pleaseseetheinstallation

and operation instructions for the level control

device.

Observe the information on the maximum

switching frequency and the minimum water

level!

5.4. Dry-running protection

Toensurethenecessarycooling,thepumpmust

beimmersedwheninoperation,dependingon

theoperatingmode.Inaddition,makesurethat

no air enters the hydraulics housing.

The pump must therefore always be immersed

intheuiduptothetopedgeofthehydraulic

housingor,ifapplicable,uptothetopedgeof

themotorhousing.Foroptimumoperational

reliability,werecommendinstallingadry-running

protection system.

Correctrunningisensuredbyoatswitchesor

electrodes.Theoatswitchorelectrodeisxed

in the sump and switches off the pump when the

water level falls below the minimum coverage

level. If the dry-running protection only includes

oneoaterorelectrodeandthelllevelsdeviate

signicantly,thenthepumpmayturnonand

off constantly! This can result in the maximum

Loading...

Loading...