Installation and operating instructions Wilo-Drain TMT 32M 29

INSTALLATION English

4.3. Storage

Newly supplied pumps are prepared so that they

can be stored for at least 1 year. The pump should

be cleaned thoroughly before it is put into tem-

porary storage.

The following should be taken into consideration

forstorage:

• Placethepumponarmsurfaceandsecureit

against slipping and falling over. Submersible

pumps are stored vertically.

DANGER due to falling over!

Never set the pump down if unsecured. If the

pump falls over, this may lead to injuries!

• Ourpumpscanbestoredattemperaturesdown

to-15°C.Thestoreroommustbedry.Werecom-

mend a frost-protected room for storage with a

temperaturebetween5°Cand25°C.

• The pump is not allowed to be stored in rooms

inwhichweldingworkiscarriedout,because

the resulting gases or radiation can damage the

elastomer components and coating.

• Suction and pressure connections must be sealed

securely to prevent contamination getting in.

• All power supply cables must be protected

againstkinking,damageandmoistureingress.

ELECTRICAL hazard!

Damaged power supply cables can cause fatal

injury! Defective cables must be replaced by a

qualied electrician immediately.

BEWARE of moisture!

Moisture penetrating the cable will damage

both the pump and the cable. Never immerse

the cable end in uid and always protect it

from moisture.

• Thepumpmustbeprotectedfromdirectsunlight,

heat,dust,andfrost.Heatorfrostcancauseseri-

ous damage to impellers and coatings!

• The impellers should be checked at regular inter-

vals. This presents jamming of the bearings and it

renewsthelmoflubricationonthemechanical

seal.

BEWARE of sharp edges!

Sharp edges can form on the impeller and

hydraulic opening. There is a risk of injury!

Wear the necessary protective clothing, such

as protective gloves.

• If the pump has been stored for a long period of

time,itshouldbecleanedofimpuritiessuchas

dustandoilresiduebeforecommissioning.Check

that the impellers move freely and check the

housing coatings for damage.

Prior to commissioning, the ll level in the

sealing chamber should be checked and topped

up, if necessary!

Damaged coatings must be repaired immedi-

ately. Only an intact coating fulls its intended

purpose.

Please note that elastomer parts and coatings

become brittle over time. If the product is to be

storedforlongerthan6months,werecommend

checking these parts and replacing them as nec-

essary.Consultthemanufacturerfordetails.

4.4. Return delivery

Pumps that are returned to the factory must be

properly packaged. This means that impurities

have been removed from the pump and that it has

beendecontaminatedifusedwithuidsthatare

hazardoustohealth.

Forshipping,thepartsmustbepackedintear-

proofplasticbagsofsufcientsizeinsucha

manner that they are tightly sealed and leak-

proof.Furthermore,thepackagingmustprotect

the pump from damage during transportation.

Ifyouhaveanyquestions,pleasecontactthe

manufacturer!

5. Installation

In order to prevent damage to the product or seri-

ousinjuryduringinstallation,thefollowingpoints

mustbeobserved:

• Installation work – assembly and installation of

thepump–mayonlybecarriedoutbyqualied

persons. The safety instructions must be followed

at all times.

• The pump must be inspected for transport dam-

age before any installation work is carried out.

5.1. General

Forplanningandoperationoftechnicalsewage

systems,observethepertinentlocalregulations

and directives for sewage technology (such as

thoseoftheGermanAssociationforWater,

WastewaterandWaste).

Notethatpressuresurgescanoccur,inparticu-

lar with stationary installations where water is

pumped with longer discharge pipes (especially

withsteadyascentsorsteepterrain).

Pressure surges can result in destruction of the

pump/systemandnoisepollutionduetoap

knock. Pressure surges can be prevented by ap-

plying suitable measures (e.g. non-return valves

with an adjustable closing time or special routing

ofthedischargepipeline).

Afterpumpingwatercontainingcalcium,clayor

cement,thepumpshouldbeushedwithpure

water to prevent encrustation and avoid related

breakdowns later on.

Ifyouareusinglevelcontrol,makesurethatthe

minimum water coverage is present. Air pockets

in the hydraulic housing or piping system must be

avoided at all costs and must be removed using

a suitable ventilation system and/or placing the

pump at a slight angle (if installed as a portable

pump).Protectthepumpfromfrost.

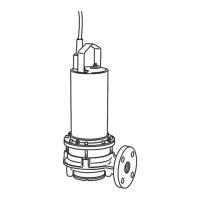

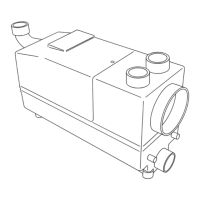

5.2. Installation methods

• Vertical portable wet well installation with

• Fixeddischargepipelineconnection

• Pressure hose

Loading...

Loading...