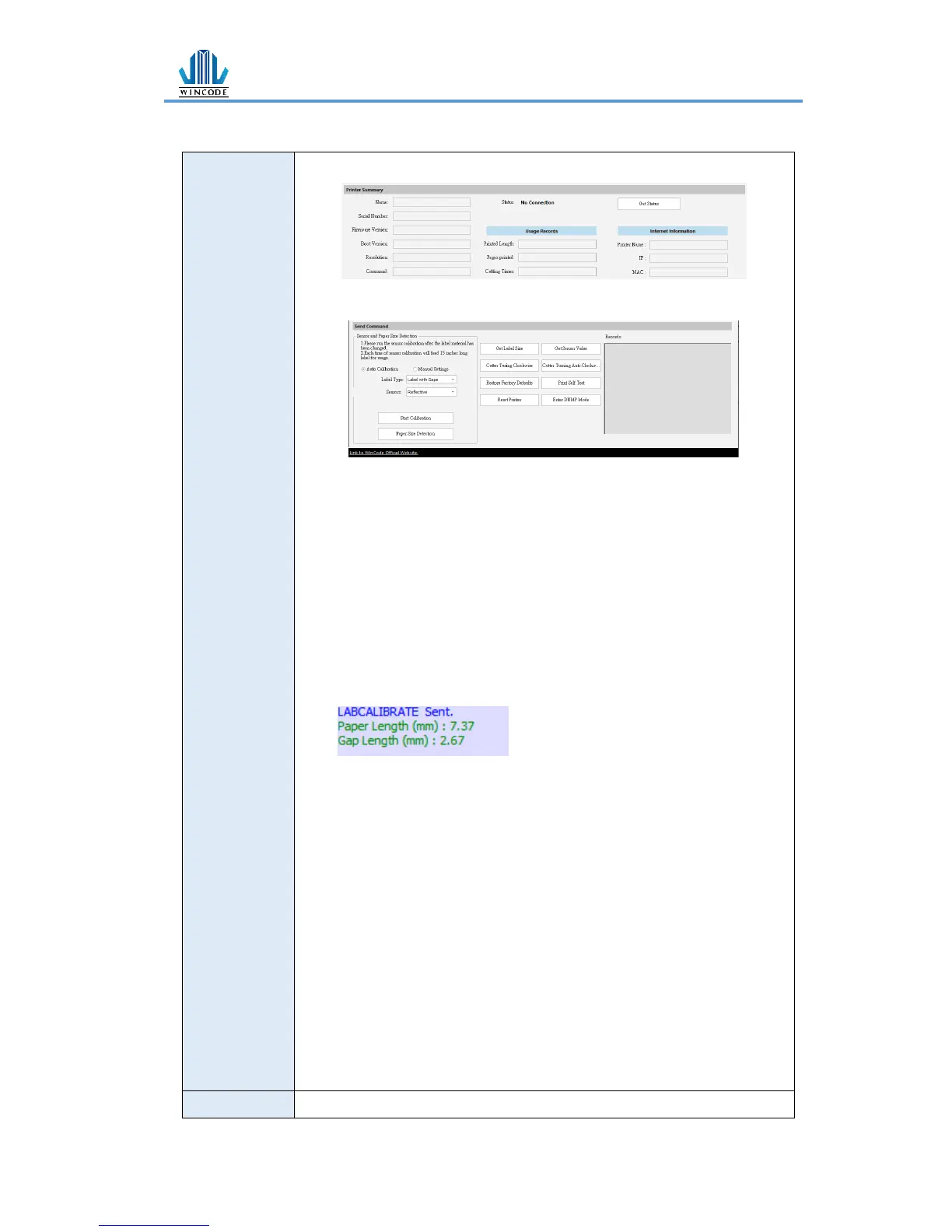

➢ Listing printer information

Send Command window

➢ Start Calibration

Please run the sensor calibration after the label material has

been changed, if it is the same material but different size and

then only need to adjust the page setup of WinLabel. It is

recommended to use the auto detection, if there are specific

materials that the sensor cannot detect, and then switch to

manual setup, select the sensor strength and set the numeral

of the sensor (The value range of sensor is from 5 to 100, less

value is more sensitive)

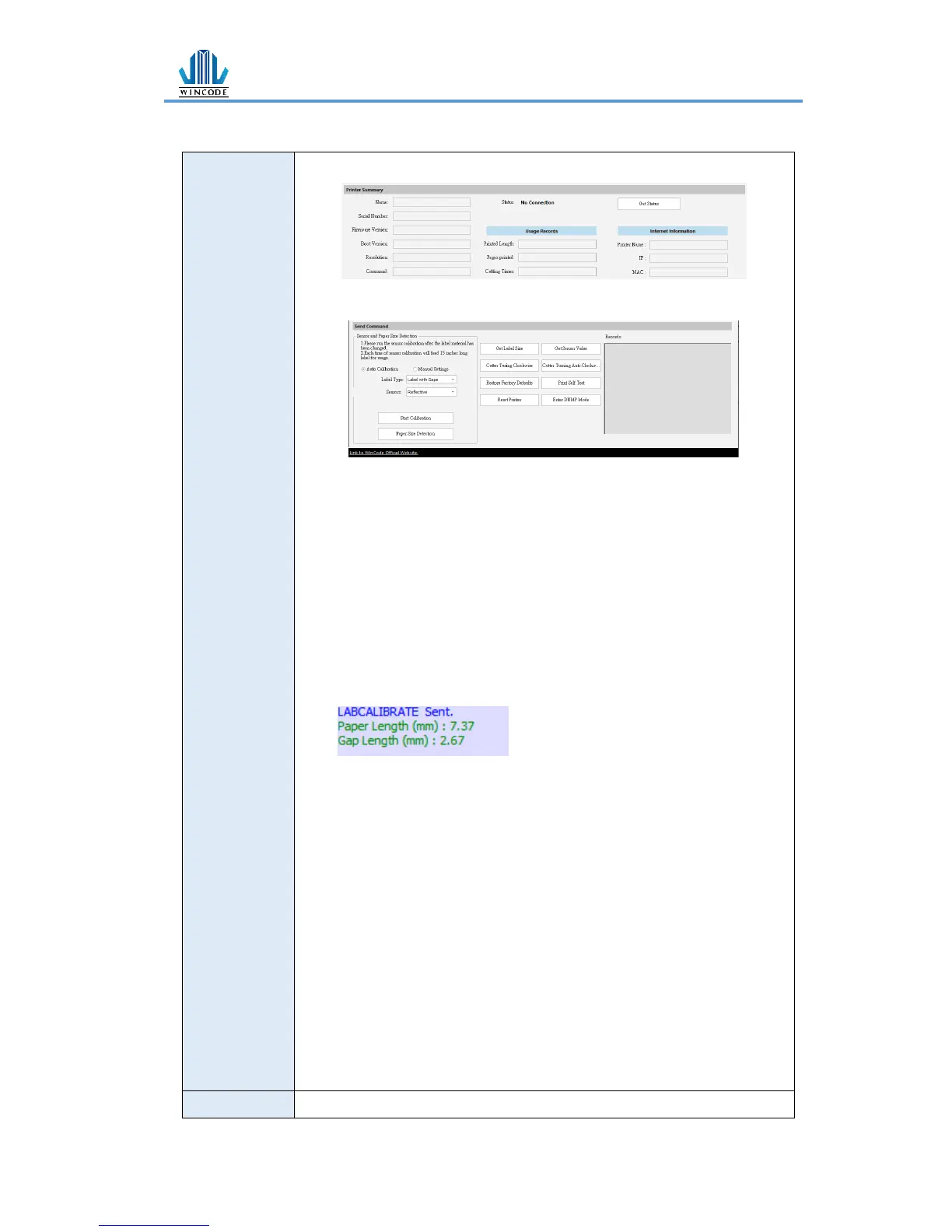

➢ Paper Size Detection

Printer will detect the paper size and get detecting result in

the right table as below Figure

➢ Get Label Size: The detecting value of label size will be showed

in the right table

➢ Get sensor value: The detecting value of sensors will be

showed in the right table

➢ Cutter Turning Clockwise: Cutter cuts label from up to down

(Fully cut)

➢ Cutter Turning Anti-Clockwise:Cutter cuts from down to up

(Not completely cut-off)

➢ Restore Factory Defaults: The parameters of printer will be

factory default setting.

➢ Printer Self Test: Printer will print the inside settings on the

label

➢ Reset Printer:Restart the printer

➢ Enter DUMP Mode: Entering to the DUMP mode (Press

“menu” to return the original mode)

Loading...

Loading...