Maintenance4103−3/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

4/ 5

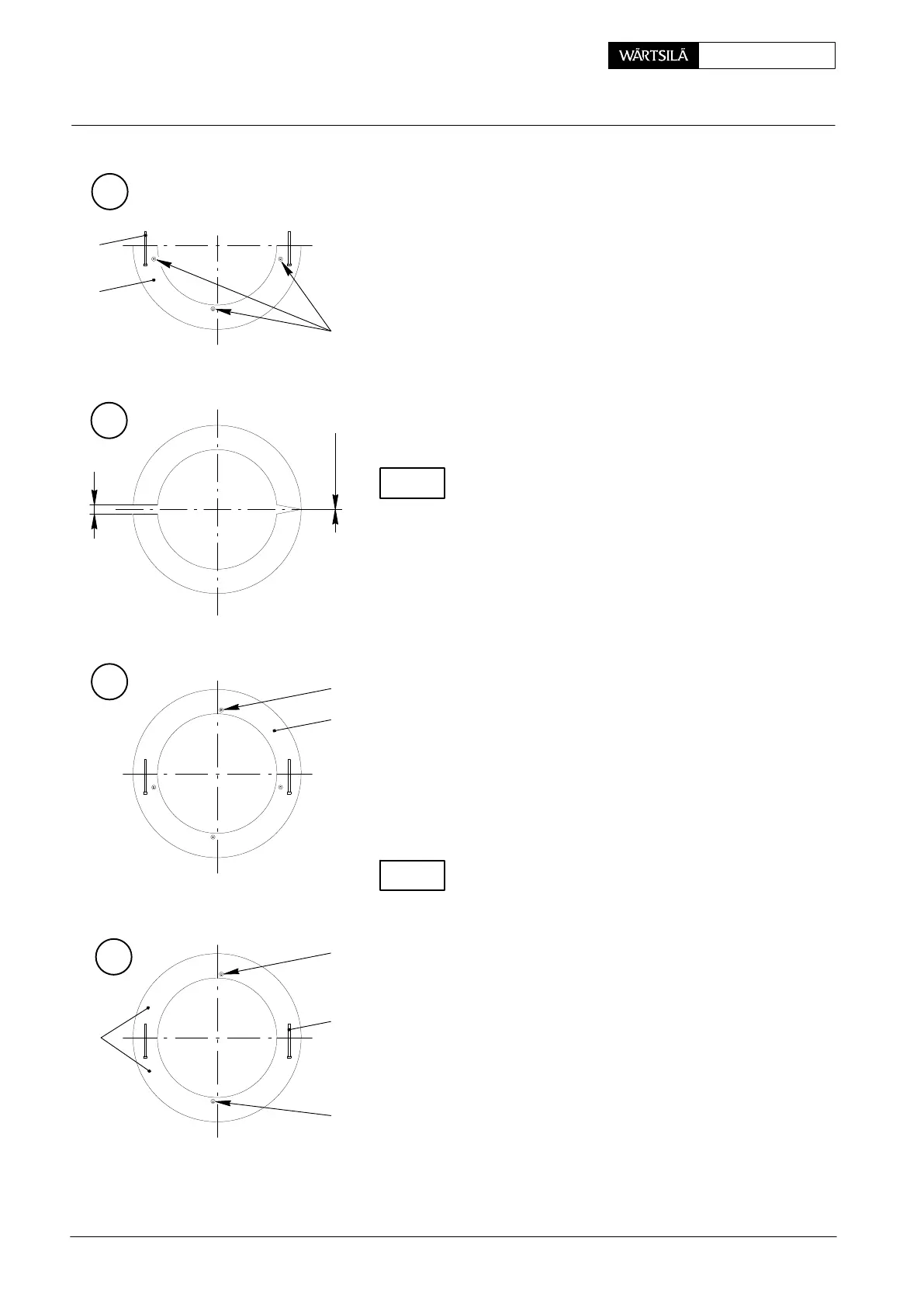

⇒ Turn the gear wheel half to the bottom (Fig. E) and

place the second gear wheel half, which is also pro-

vided with two pre-assembled elastic studs 3, on the

top (Fig. G).

D Check the correct diameter tolerance by measuring

the size of the gap between both gear wheel halves.

For that the gap must be closed on the opposite side

(Fig. F).

Gap ‘j’ must be 0.16 mm ... 0.41 mm. If the dimension is

not within the mentioned tolerance, the gear wheel must

not be assembled, but the center hole has to be given an

appropriate re-machining (see Preparing the assembly

of the gear wheel).

⇒ After measuring, align the gaps between the wheel

halves and slightly tighten castle nuts 4 of elastic

studs 3 (Fig. C).

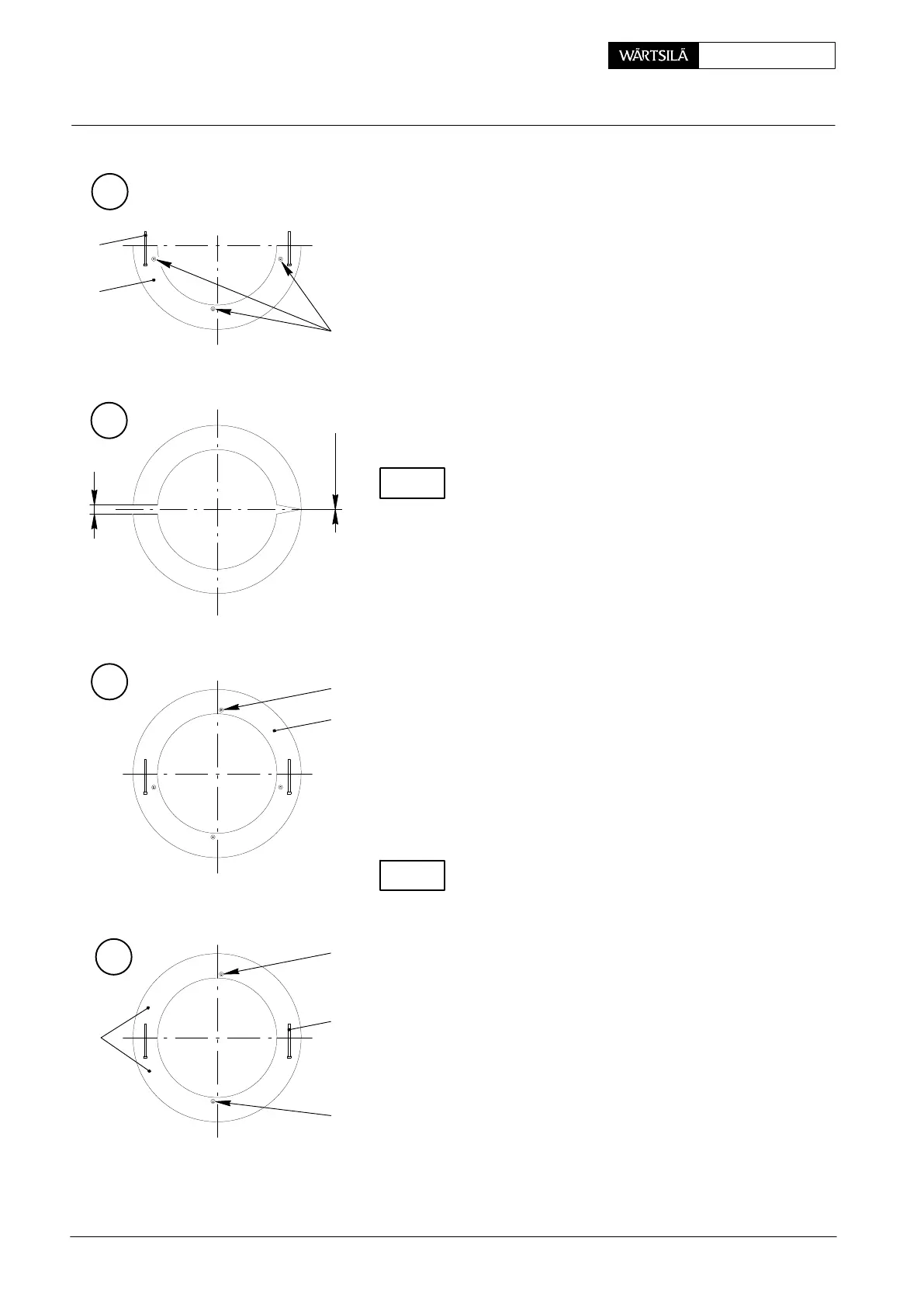

⇒ Also insert a flange screw 6 in the centre of upper

gear wheel half and tighten it temporarily (Fig. G).

⇒ Remove flange screws 6 from each end of the lower

gear wheel half so that there are now only two flange

screws 6, each of them tightened temporarily in the

centres of the upper and the lower gear wheel half

(Fig. H).

CHECK

There must be no clearance on the seating surfaces be-

tween the gear wheel and the crankshaft flange − check!

⇒ For fitting the four remaining castle nuts 4 belonging

to elastic studs 3 (Fig. C), apply MOLYKOTE paste

to the threads and the seating surfaces. Tighten only

the castle nuts treated with MOLYKOTE paste. Use

fork wrench 94412E (Fig. I) for holding up the castle

nuts opposite which have already been fitted and se-

cured with LOCTITE and a split pin.

⇒ Tighten the four castle nuts of elastic studs 3 cross-

wise by means of ring slugging wrench 94002−46,

measuring and recording the length of the elastic

studs beforehand.

CHECK

E

6

3

1

F

G

j

GAP 0

6

1

H

6

3

6

1

001.167/97

001.166/97

001.166/97

001.166/97

2013 / V2

Replacing the Gear Wheel on the Crankshaft

Loading...

Loading...