Maintenance5552−2/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

6/ 11

5. Fitting of bearings and camshaft

The fitting of bearings and camshaft is carried out analogously but in reverse se-

quence to the removal, whereby the following points require special attention:

The camshaft can be installed in every position, however:

D all parts to be fitted must be clean and undamaged!

D for the assembly apply oil to bearing shells, thrust bearing ring halves and

camshaft.

D take care of the designations of reused bearing shells.

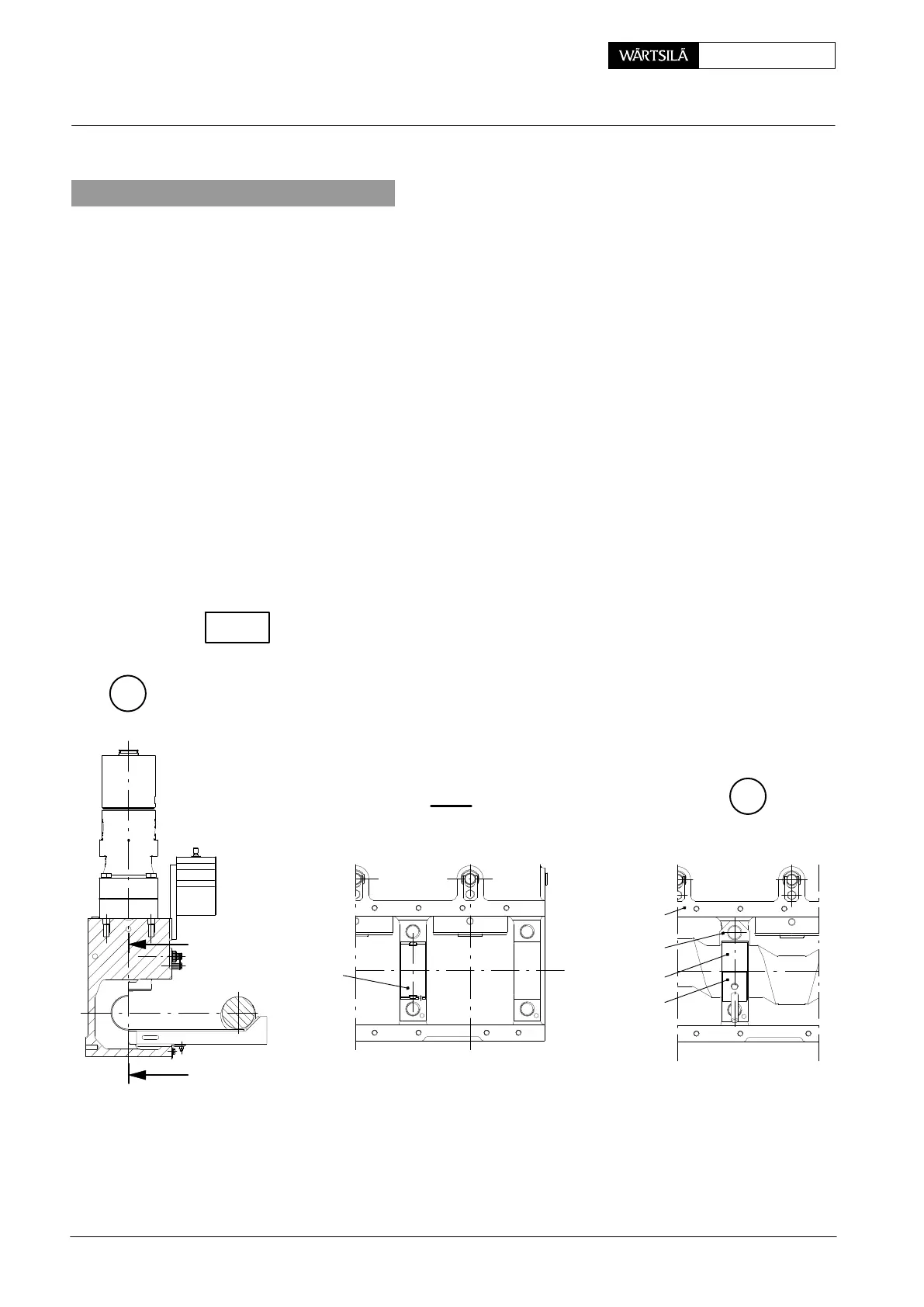

D fit bearing shells, so that their bores provided for dowel pins 17 in the bearing

covers point to the same side (Fig. ’C’ and ’D’).

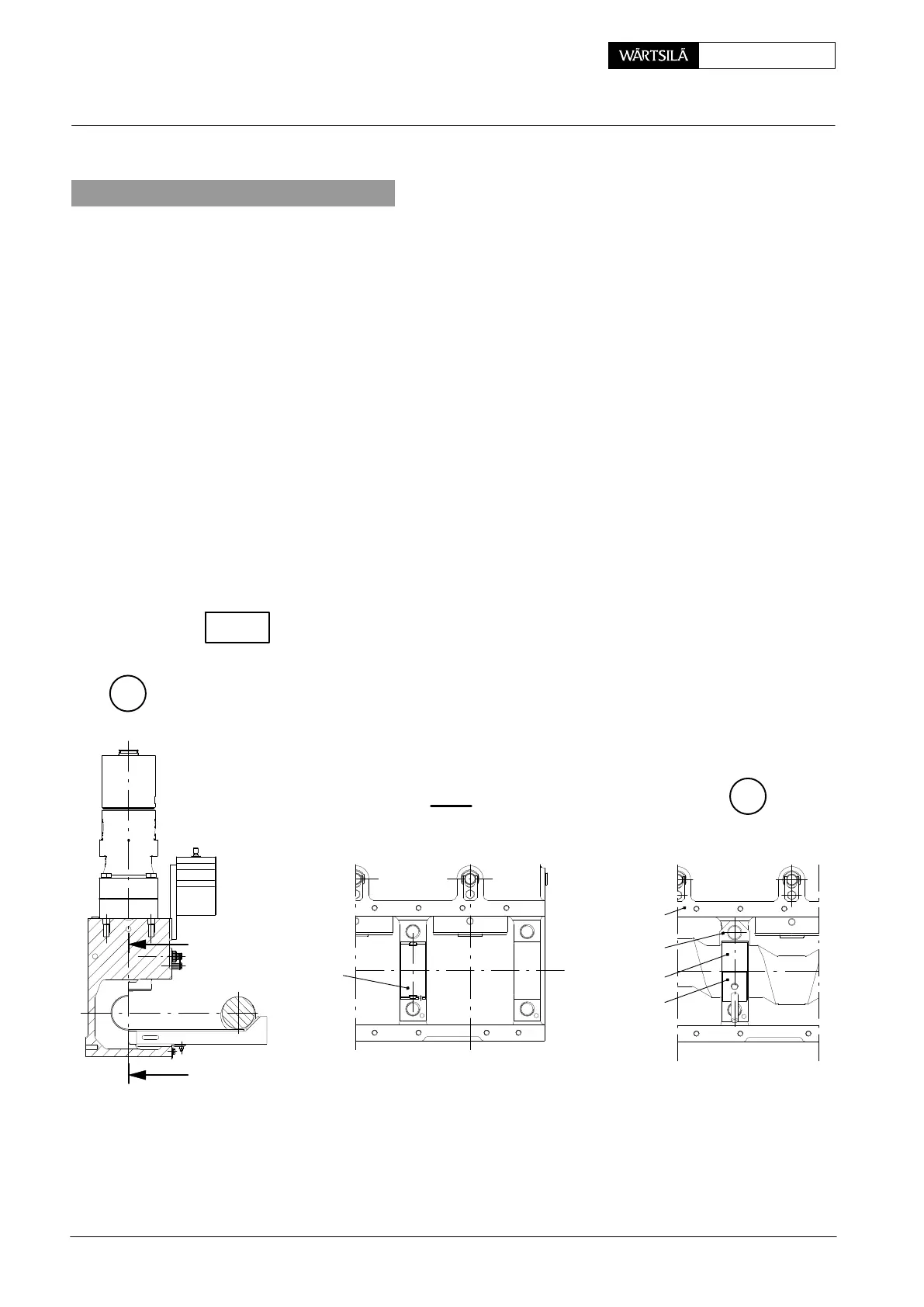

D in order to align the bearing shell, centring device 94566B provided for this

purpose is inserted into the corresponding tap hole of the elastic screw as

shown in Fig. ’M’.

D take care of bearing cover numbering and meshing of dowel pin 17 (Fig. ’D’).

D apply oil to the threads and seating surfaces of elastic screws 7 and tighten

these equally with a torque of 1450 Nm (for the application of torque amplifier

20 see section 6).

After tightening the elastic screws there must be no clearance at ’x’ (Fig. ’D’,

section II-II)!

L

012.994/05

I

I

18

10

94566B

19

94567

M

I - I

2013 / V2

Supply Unit: Removal and Fitting of Camshaft and Bearing Shells

CHECK

Loading...

Loading...