Maintenance9223−1/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

12/ 22

008.744/01

008.744/01

008.743/01

008.742/01

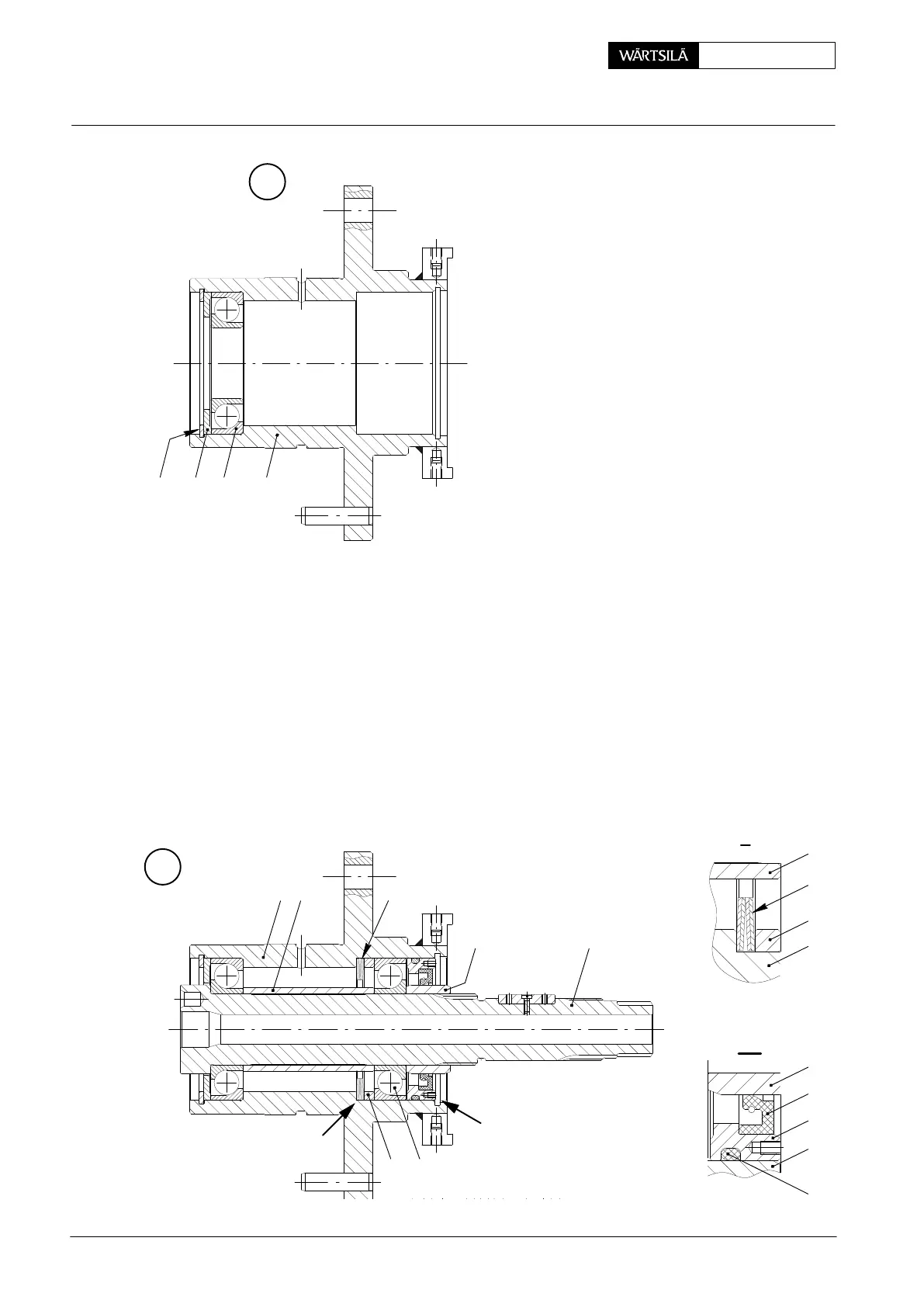

6.2 Sub-assembly of bearing housing

⇒ Remove the parts which are fitted on shaft 5

as shown in Fig. ’O’.

⇒ Oil ball bearing 32a and insert it into housing

14. Pay attention to the fitting position in para-

graph 6.1!

⇒ Place disc 37 with its smaller seating surface

pointing to the ball bearing and fit circlip 36.

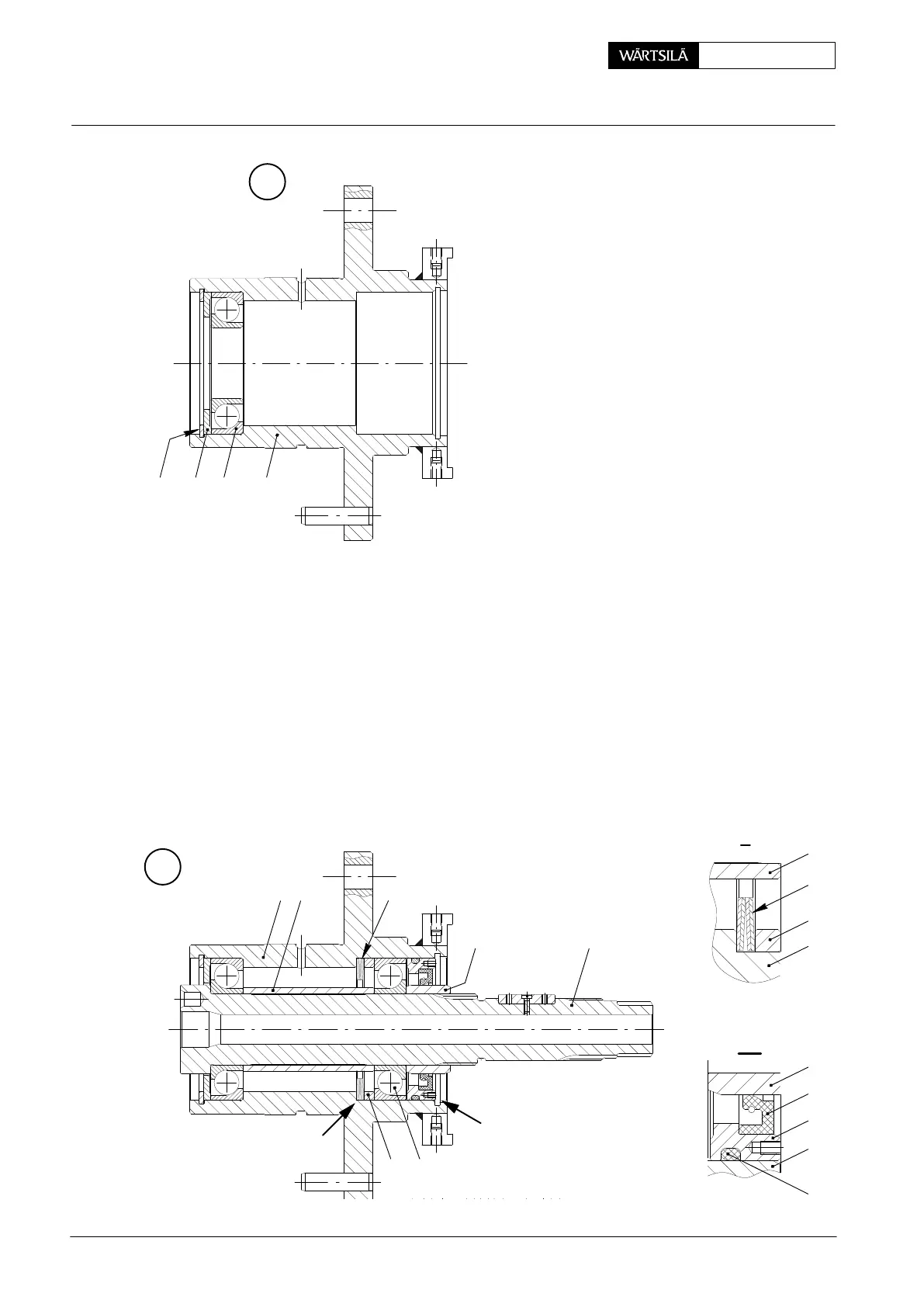

6.3 Completing of the bearing housing

⇒ Oil all parts.

⇒ Fit shaft 5.

⇒ Push distance sleeve 34 onto the shaft.

⇒ Fit disc springs 35 according to view I.

⇒ Fit distance ring 33 with thickness ’x’ determined under paragraph 6.1.

⇒ Oil ball bearing 32 and insert it into housing 14. Pay attention to the fitting

position in paragraph 6.1!

⇒ Fit retaining ring 29 with new sealing ring 30 and O-ring 60 according to view

II.

⇒ Fit distance ring 31.

31

30

29

14

33

14

35

II

I

34

Q

1432a3736

R

33

3514

34

31 5

32

I

II

2013

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Loading...

Loading...