Maintenance9223−1/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

16/ 22

8.4 Fitting the compression spring

⇒ Loosen clamp screws 55 of spring tensioner

52 (Fig. ’X’). Replace locking plates. Apply

MOLYKOTE paste G to threads and seating

surfaces of screws 55 and refit them.

⇒ Oil and adjust all adjusting screws 54 to

’x’ = 10 " 0.10 mm (Fig. ’Y’).

⇒ Insert compression springs 42, fit spring ten-

sioner with screws 53 and new locking plates,

applying MOLYKOTE paste G to threads and

seating surfaces.

⇒ Tighten screws 53 with a torque of 60 Nm and

lock them.

008.751/01

008.750/01

008.749/01

8.2 Removing the compression spring

⇒ Loosen screws 53 and remove them together with

spring tensioner 52.

⇒ Remove and check compression springs.

Remark: When replacing only one compression spring

42, it is recommend to remove also the second spring

tensioner for carrying out further adjustments.

Check spring seating surface for wear.

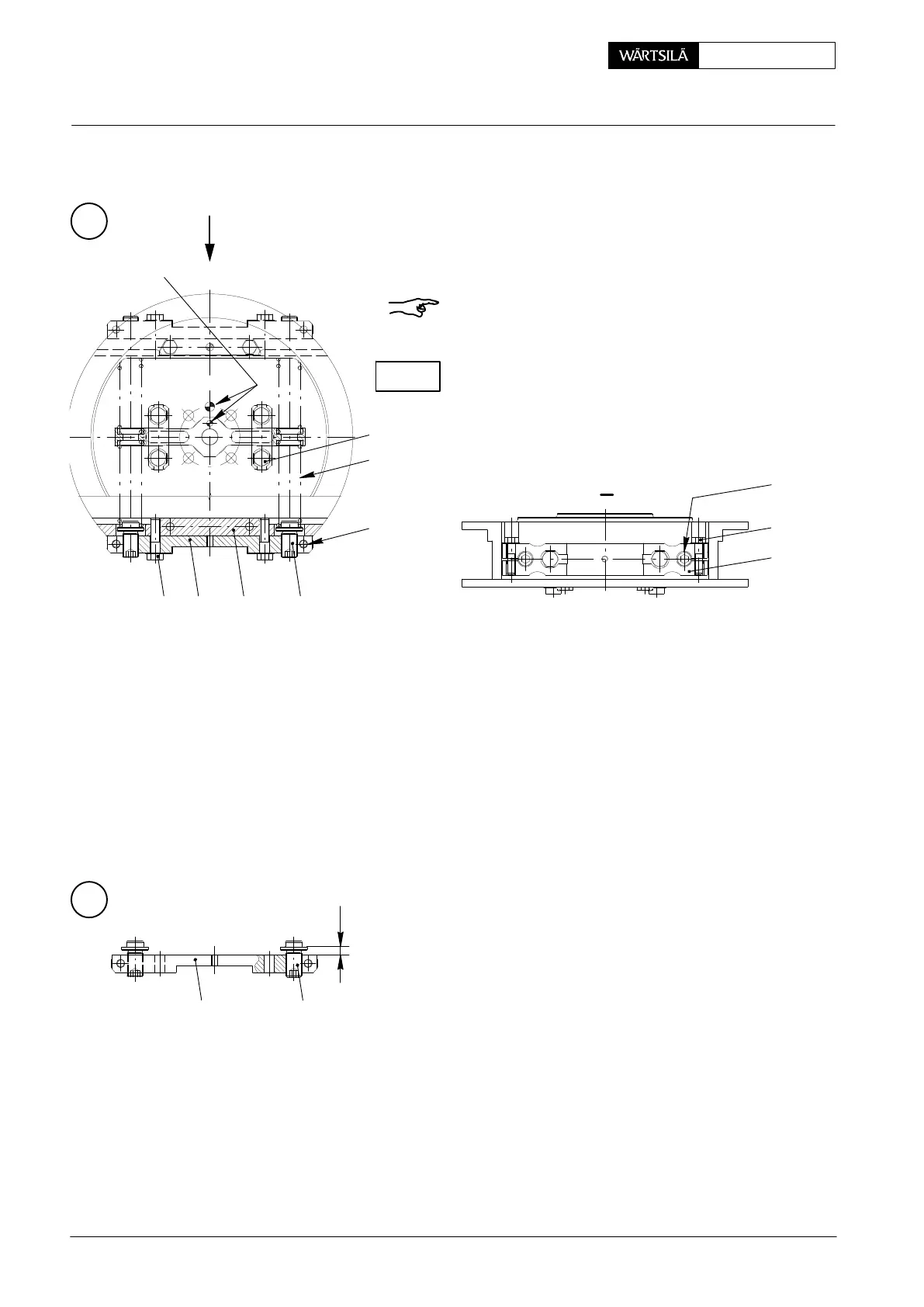

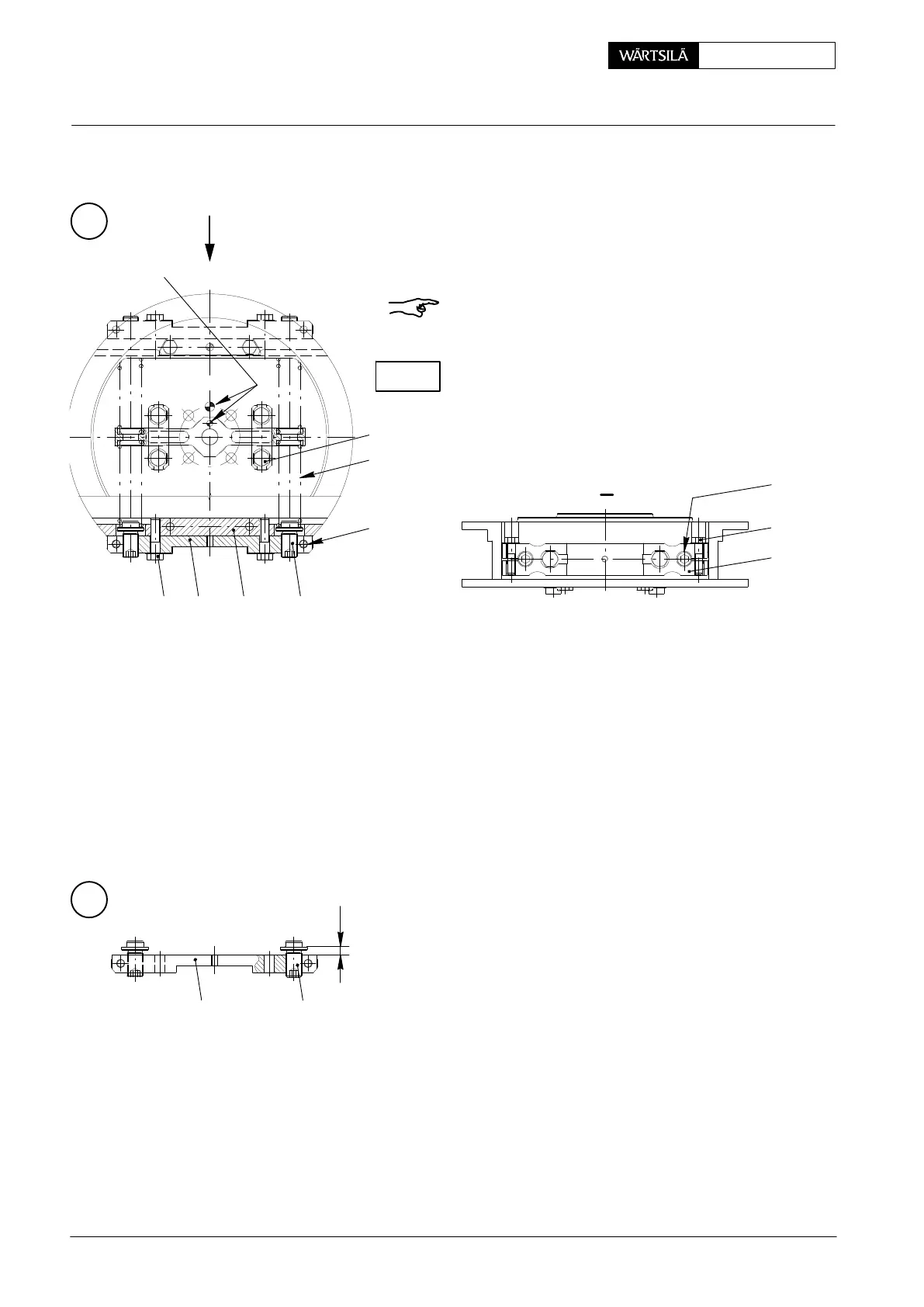

Y

I

x

54

55

52

5452

X

I

53 52 51 54

55

42

57

FITTING

POSITION

8.3 Fitting of the lever

⇒ When fitting lever 43 pay attention to its fitting position (Fig. ’X’).

⇒ Replace locking plates to screws 57.

⇒ Apply MOLYKOTE paste G to threads and seating surfaces of screws 57.

⇒ Tighten screws 57 with a torque of 60 Nm and lock them.

CHECK

2013

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Loading...

Loading...