Marine Installation Manual 2021-08 xii

List of Figures

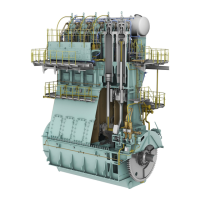

X72DF

4-54 Air filter size (example for 8-cyl. engine) . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

4-55 Arrangements for PTO, PTI, PTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

4-56 FPP with mandatory frequency converter . . . . . . . . . . . . . . . . . . . . . . . . 4-105

4-57 CPP in combination with an optional frequency converter . . . . . . . . . . 4-106

4-58 CPP in constant speed operation without frequency converter . . . . . . 4-106

4-59 CPP with two fixed operation speeds without frequency converter. . . 4-107

5-1 Engine automation architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Engine management and automation concept . . . . . . . . . . . . . . . . . . . . 5-2

5-3 Remote control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-4 Propulsion control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-5 Manoeuvring speed/power settings for FPP/CPP installations . . . . . . 5-8

5-6 Full sea load steps in FPP load-up program . . . . . . . . . . . . . . . . . . . . . . 5-9

5-7 Full sea load steps in CPP load-up program. . . . . . . . . . . . . . . . . . . . . . 5-10

5-8 The WiDE system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5-9 The WiDE installation process map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

6-1 External mass forces and moments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Major components and details of the iELBA. . . . . . . . . . . . . . . . . . . . . . 6-3

6-3 Locating an electrically-driven compensator . . . . . . . . . . . . . . . . . . . . . 6-4

6-4 Forces through the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-5 Lateral vibration — X-type and H-type . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-6 General arrangement of hydraulic type stays for one-side

installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-7 General arrangement of hydraulic type stays for both-side

installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-8 Arrangement of longitudinal stays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-9 Vibration dampers (spring type and viscous type). . . . . . . . . . . . . . . . . 6-14

6-10 Example of axial vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-11 Resulting vibration from SPS combinations . . . . . . . . . . . . . . . . . . . . . . 6-19

6-12 Synchro-Phasing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Loading...

Loading...