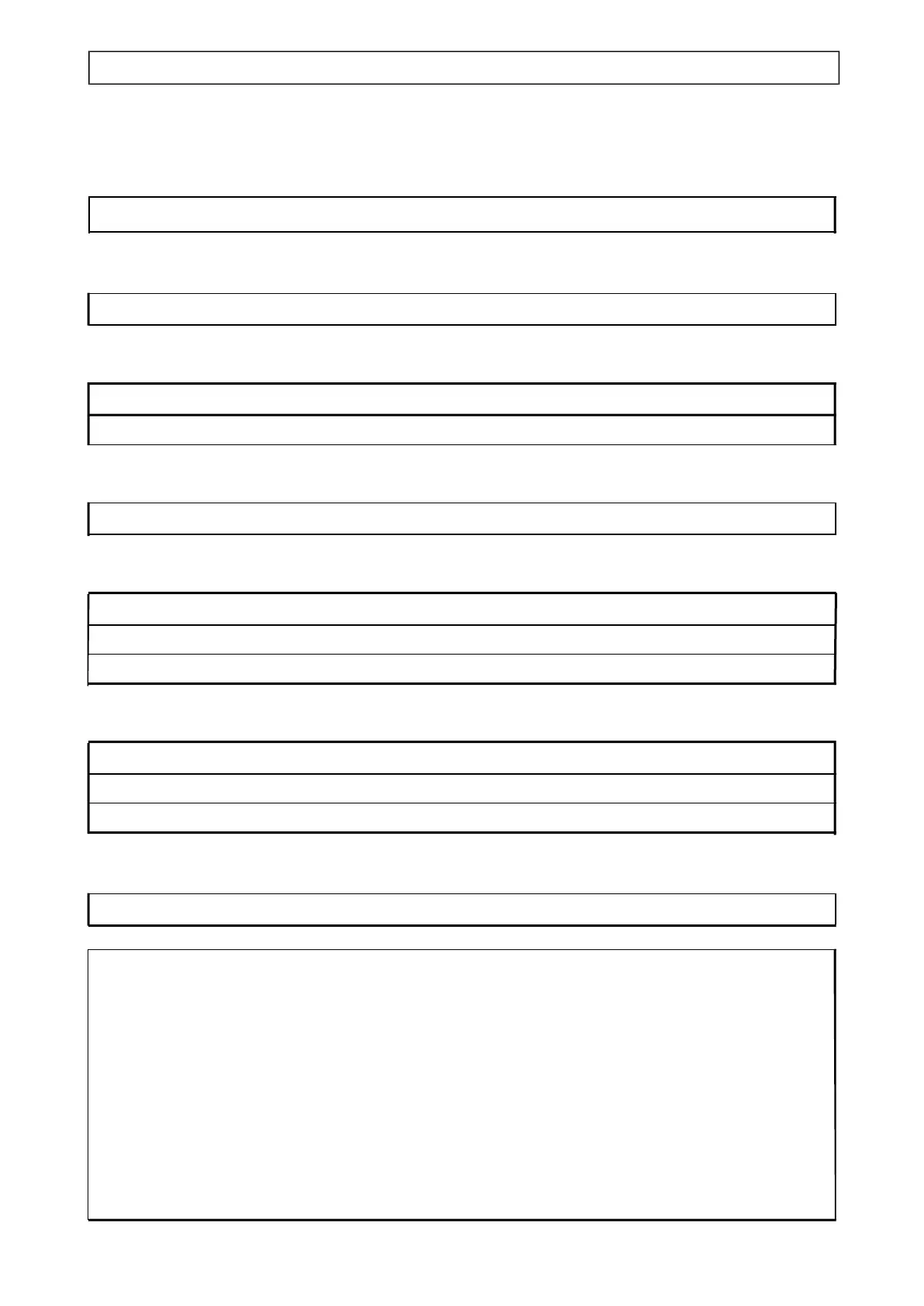

SERVICE 3.3

SERVICE SCHEDULE

SERVICE OPERATION REFERENCE PAGE

Every 125 operating hours, the above and the following

Air cleaner element Engine 3.9

Every 250 operating hours, the above and the following

Engine oil and filter Engine 3.5

Fuel filter Engine 3.7

Every 300 operating hours, the above and the following

Hydraulic oil filter Hydraulic system 3.17

Every 500 operating hours, the above and the following

Air cleaner element Engine 3.9

Fuel filter Engine 3.7

Frame assembly bolts Check all structural nuts & bolts for tightness.

Every 1000 operating hours, the above and the following

Hydraulic oil & filter Hydraulic system 3.17

Gearbox / Transfer box oil change Gearbox / Transfer box 3.10

Axle oil change Axles 3.23

Every 2000 operating hours, or 2 years, the above and the following

Brake system overhaul Braking system 3.20

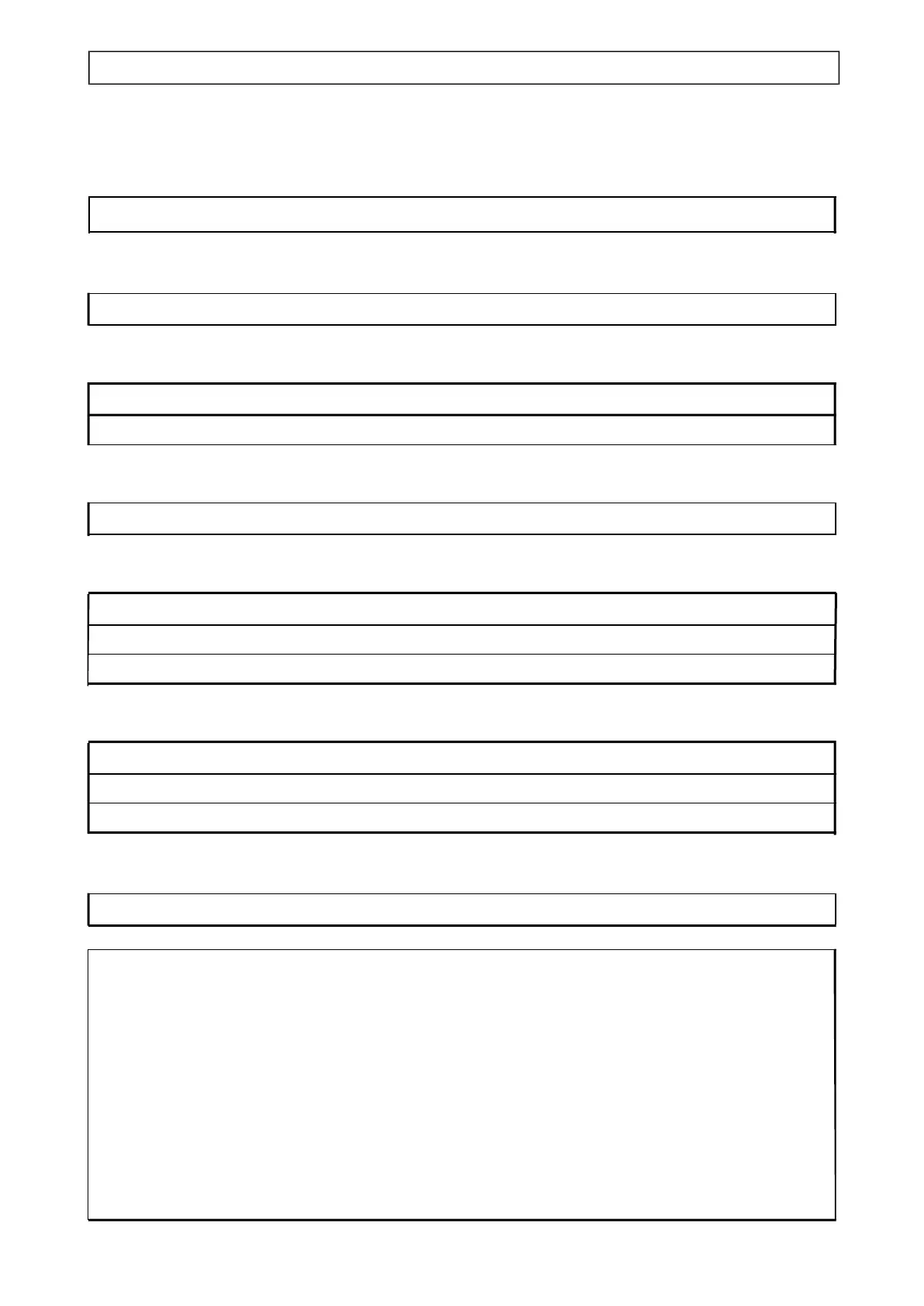

Extra services

Dirty working conditions

Increase the frequency of all services during extremes of dirt, heat and cold,

especially those relating to clean air, cooling efficiency, lubrication and machine

cleanliness.

Laying-up protection

When a machine is to remain idle, remove the battery to the workshop. Seal all

openings: air intake, exhaust breathers. Grease bright parts and protect rubber

components from direct sunlight. Fill the fuel tank, check the tyre pressures

and exhaust any pressure from the hydraulic system.

Loading...

Loading...