Every 10 operating hours, or

daily

Check for leaks

Check for oil leaks around joints and

seals.

Every 50 operating hours, or

weekly

Tighten securing nuts

Tighten axle arm/main case joint securing

nuts and half shaft nuts.

Axle oil level

Do not check the oil level until the

machine has stood for 2 minutes.

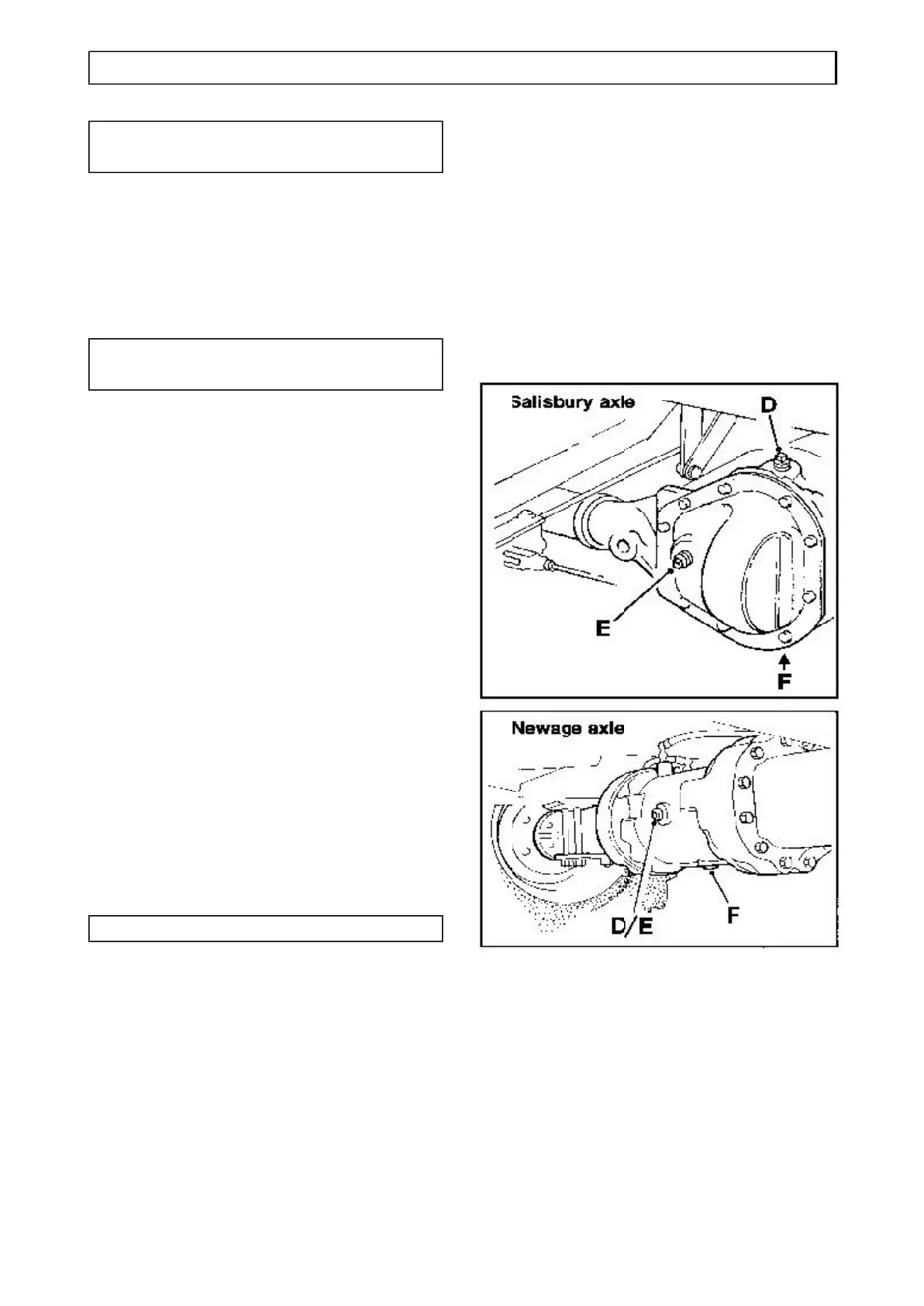

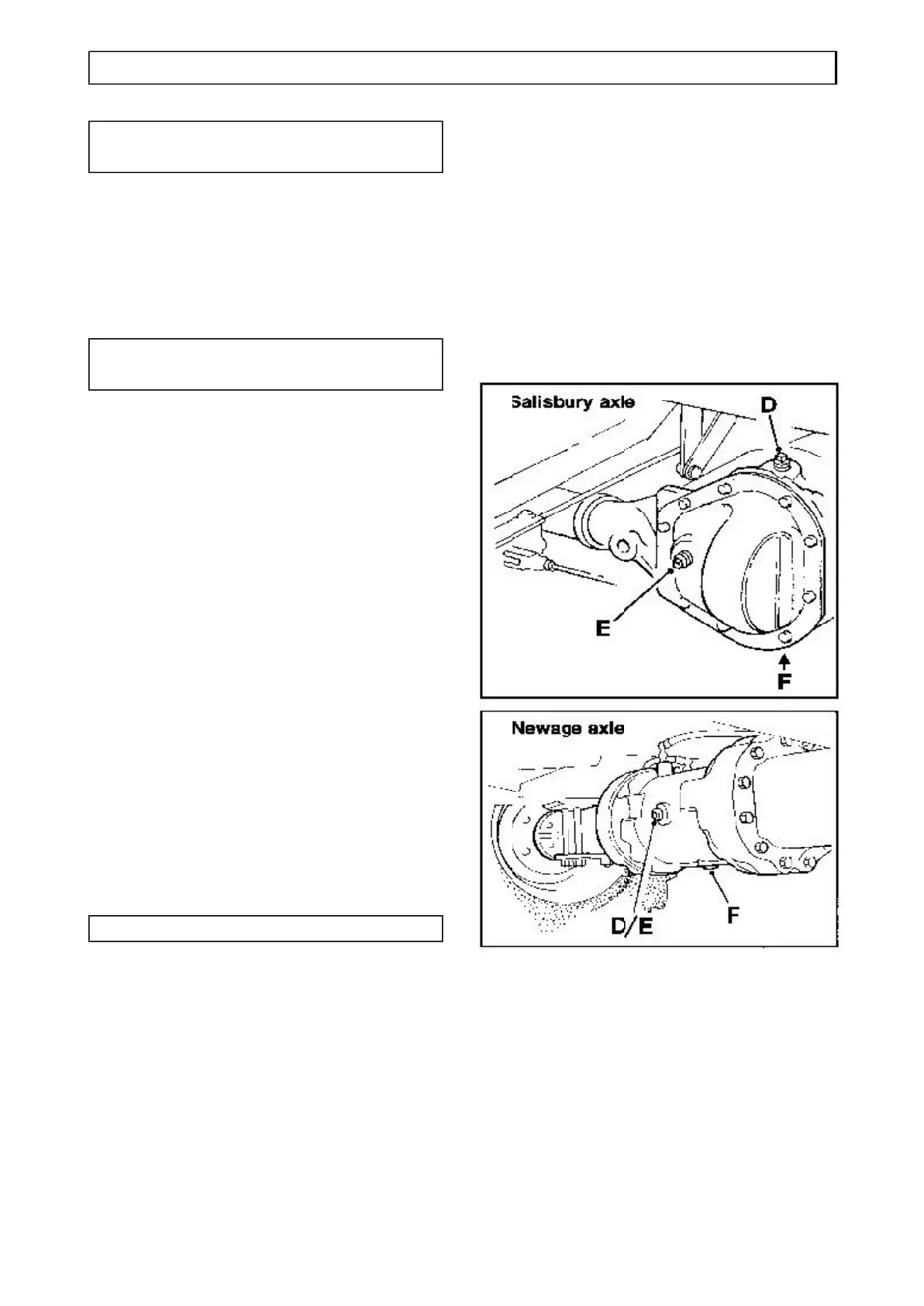

Clean the area surrounding level plug (E)

before removing it.

The oil is correct when level with the

bottom of the level plug hole.

If the level is low, top-up with clean oil of

the correct grade through the filler (D).

Replace plugs.

For the correct type and grade of oil, see

“Specifications”.

Every 1000 operating hours

Axle oil change

Change the lubrication oil in the front axle

as follows:

Clean the area surrounding the filler (D),

level (E) and drain (F) plugs.

Place a suitable container beneath the

drain plug.

CAUTION: Before removing the plugs be

sure to stand to one side to avoid the oil

that will spill from the drain hole.

Remove drain plug (F) and drain oil from

the casing. Replace drain plug.

Refill at the filler plug (D) with clean oil of

the correct grade.

The level is correct when oil reaches the

bottom of the level plug hole (E).

Replace all plugs.

For the correct type and grade of oil, see

“Specifications”.

SERVICE 3.23

AXLES

Loading...

Loading...