GMZ-E Operating manual Page 14 of 31 B0668

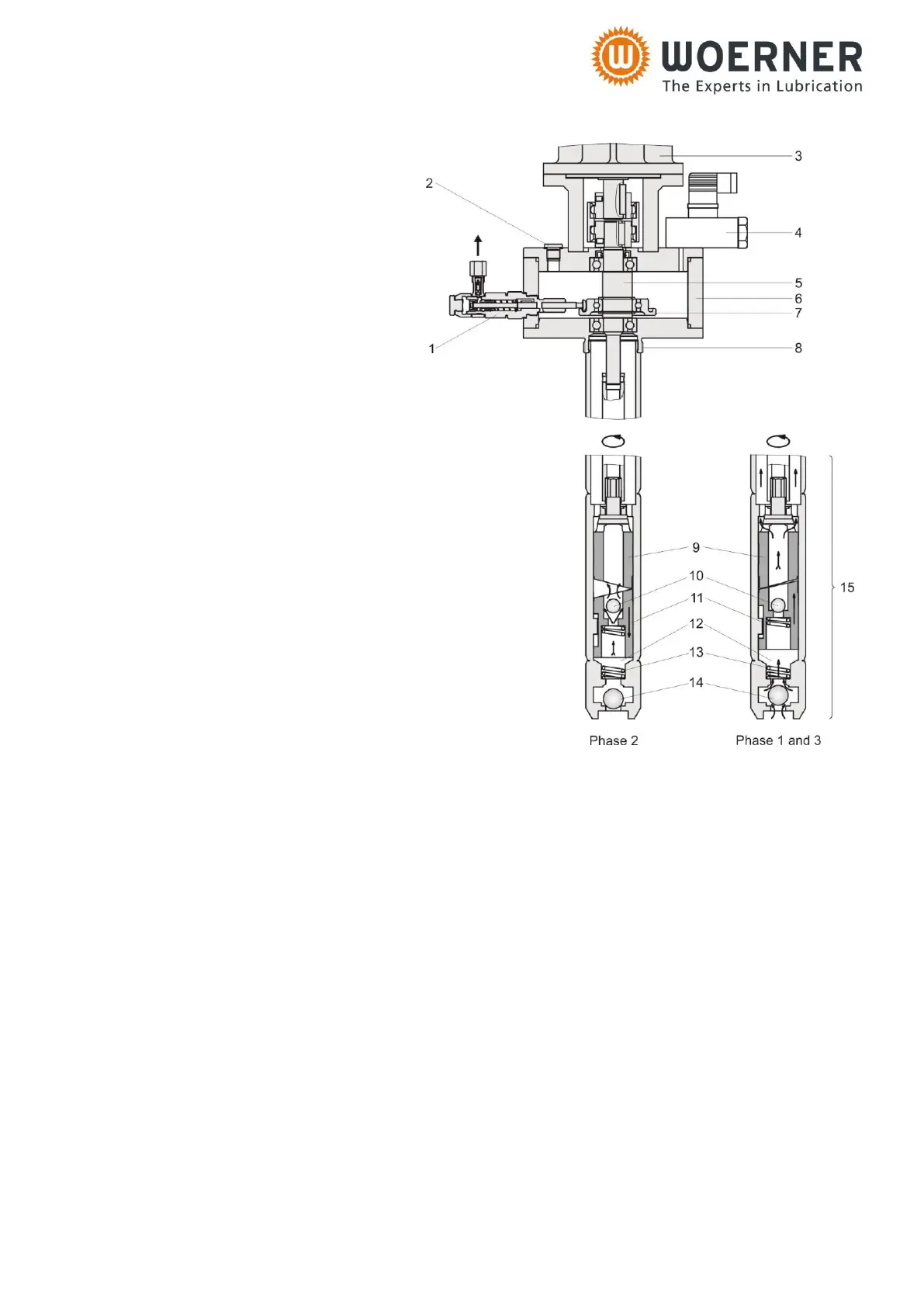

4.3 Functioning

1 Pump element

2 Vent screw G 1/4

3 Gear motor

4 Pressure monitor

5 Eccentric shaft

6 Pump casing

7 Pressure ring

8 Threaded connection G2

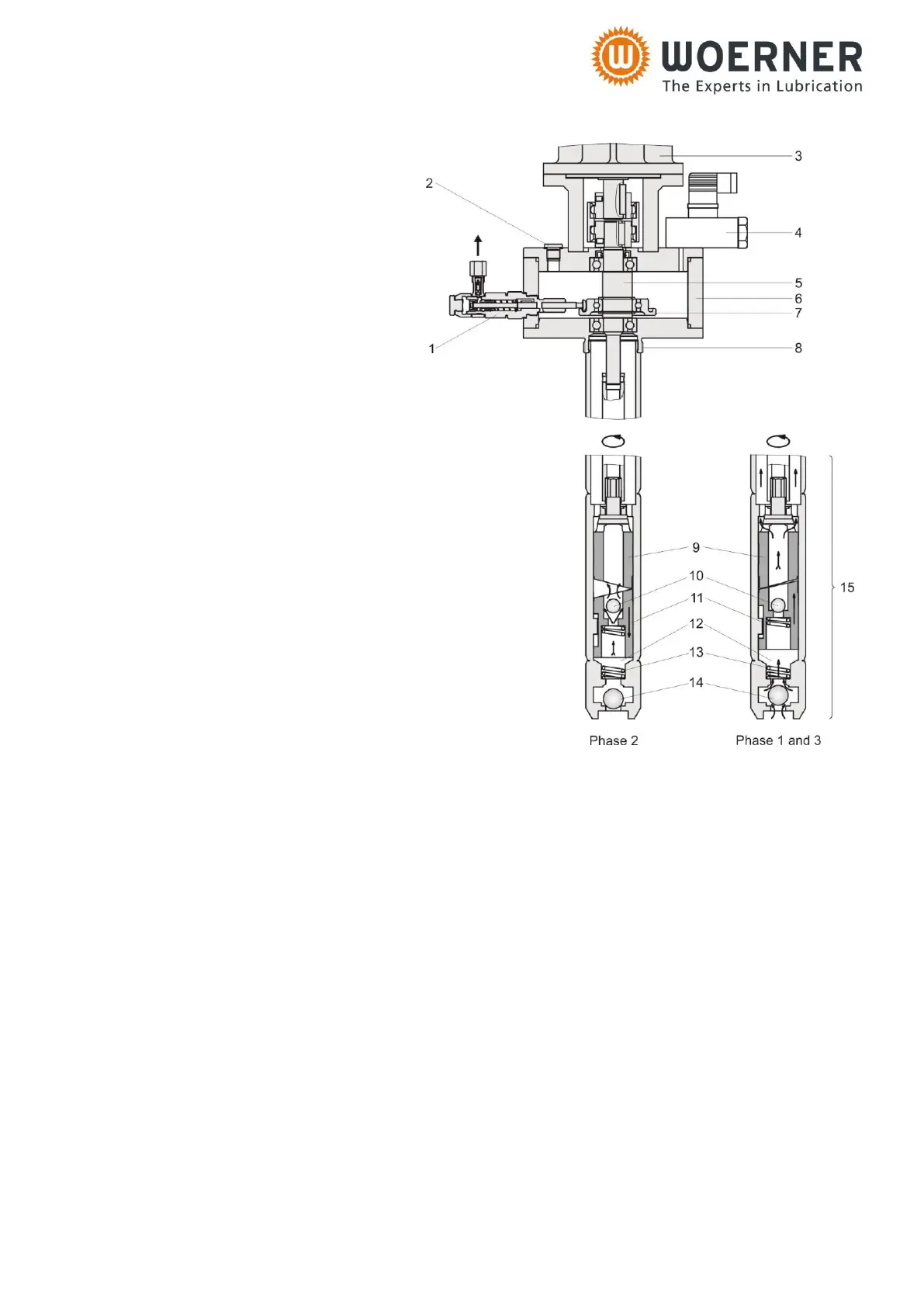

9 Control piston

10 Check valve

11 Delivery piston

12 Intermediate chamber

13 Pressure spring

14 Check valve

15 Delivery pump

The barrel pump consists of the

following components:

Feed pump (15), pump housing

(6), pump elements (1) and drive

motor (3). The feed pump (15) is

powered by the drive motor (3)

via the vertical eccentric shaft (5).

Phase 1

During the suction stroke the delivery piston (11) forced downward by the control piston (9) is

pressed upward again by the compression spring (13). The vacuum resulting in the

intermediate chamber (12) causes the lubricant to be drawn in via the non-return valve (14).

Phase 2

During the next half revolution of the control piston (9), the delivery piston (11) is forced

downward again and the lubricant contained in the intermediate chamber (12) is delivered in

upward direction via the nonreturn valve (10).

Phase 3

Further rotation of the control spool (9) through 180° results in a new suction stroke and the

non-return valve (10) closing at the same time enables the spring-loaded delivery piston (11)

to force the lubricant above it into the upper pump housing (6).

The pressure monitor (4) signals "barrel empty" when no more lubricant is delivered by the

feed pump (15), however there is still lubricant left in the pump housing.

The vertical eccentric shaft (5) drives a pressure ring (7) to which the pump elements (1) are

attached. Due to the eccentricity of the pressure ring (7) each delivery piston performs one

constant delivery and suction stroke per pump shaft revolution.

The pump elements (1) draw accurately metered quantities of lubricant (dependent on element

adjustment) from the lubricant reservoir in the pump housing (6).

Loading...

Loading...