GMZ-E Operating manual Page 15 of 31 B0668

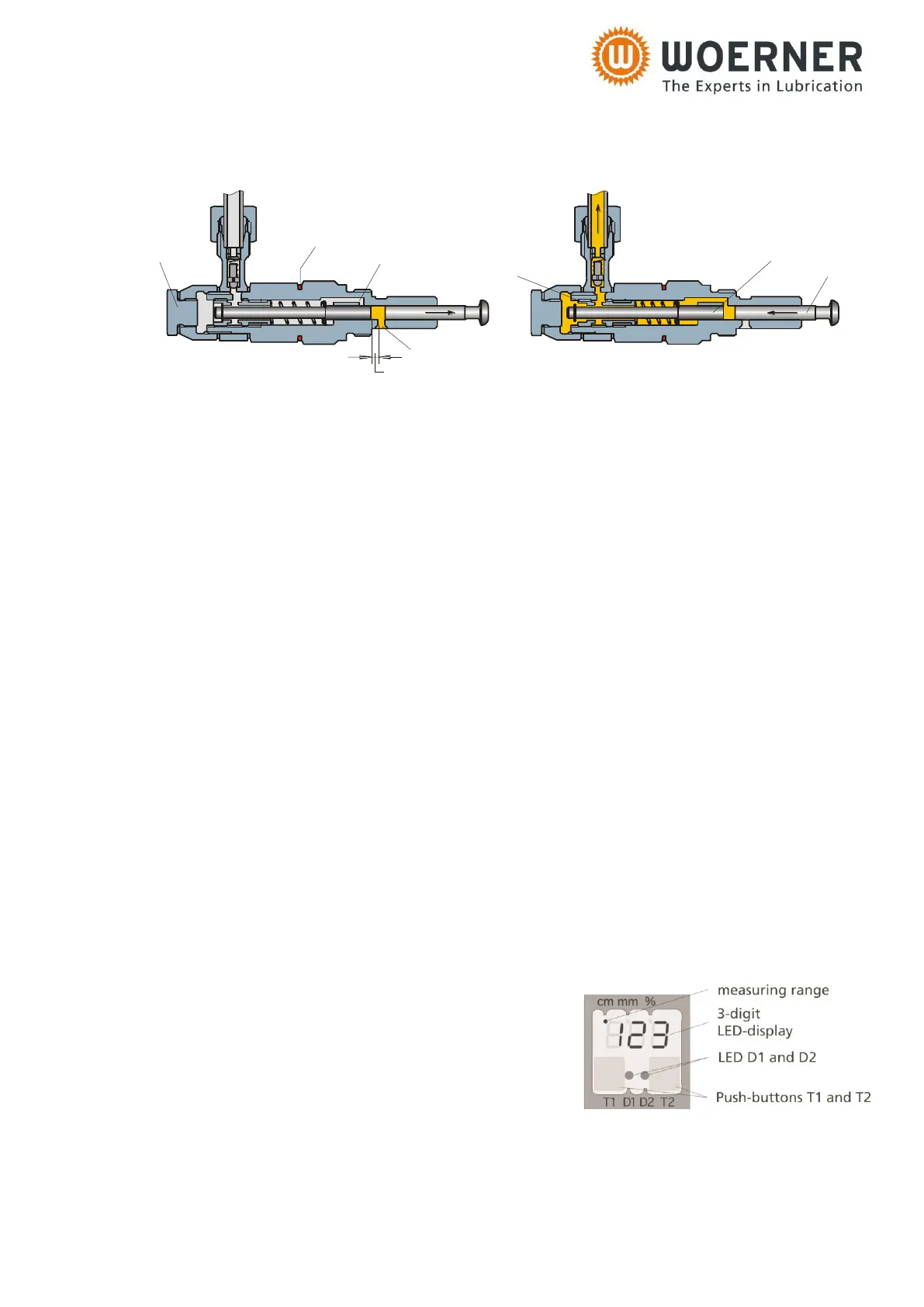

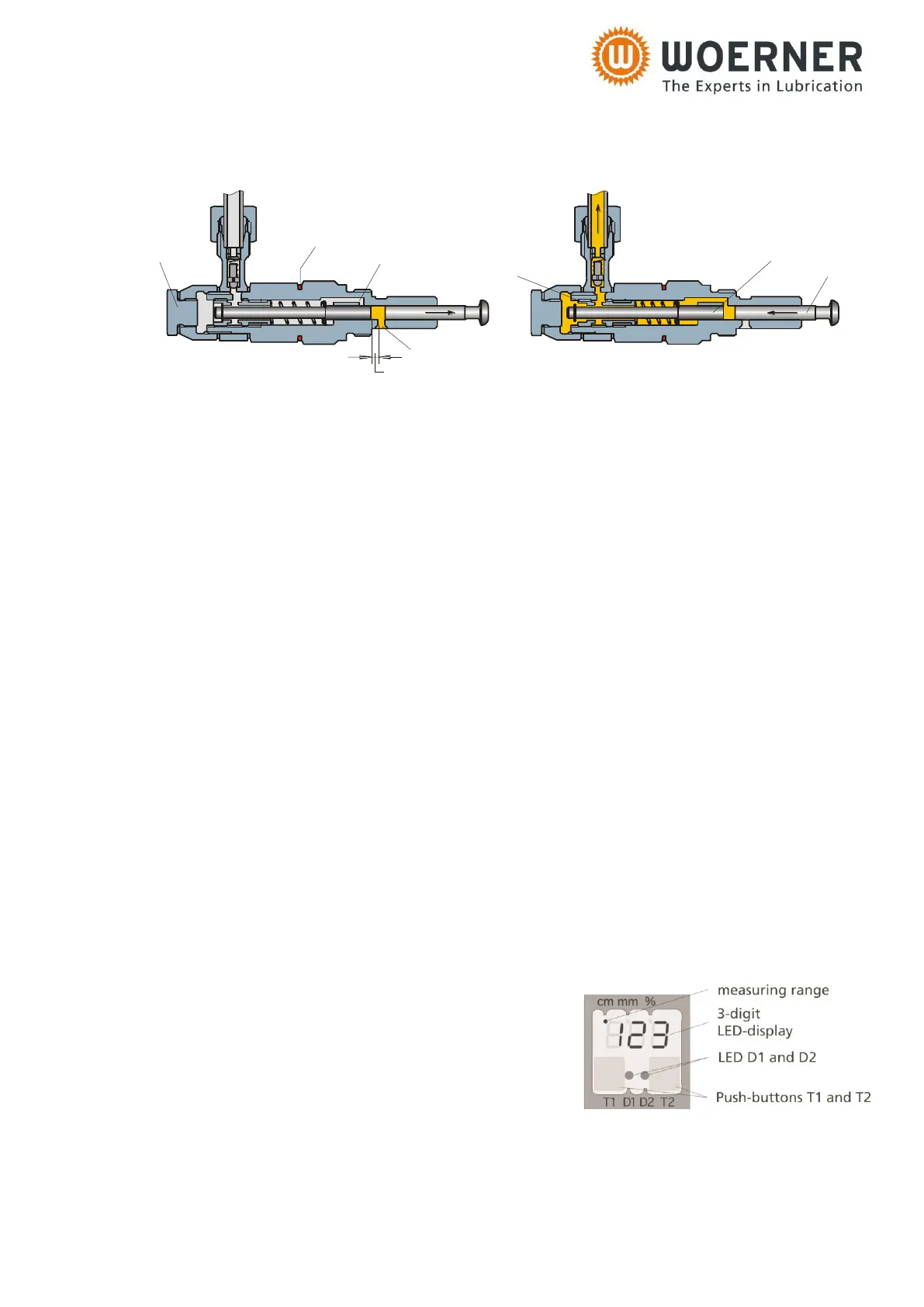

4.4 Pump elements

The suction stroke is performed by delivery piston 1 and control piston 2. In this action,

delivery piston 1 is actuated by the eccentric shaft, and control piston 2 is actuated by the

spring. The control piston closes delivery hole 3 and is retained in a certain position depending

on the delivery volume set. The delivery piston continues to move. As a result, a vacuum is

built up in the metering chamber. After opening of suction hole 4 by the delivery piston,

lubricant will be drawn from the reservoir.

In delivery stroke, delivery piston 1 moves to the left. In this motion, suction hole 4 will be

closed and control piston 2 displaced by the lubricant being available in between the delivery

piston and the control piston until it releases delivery hole 3 and the lubricant is delivered by

the delivery piston to the outlet.

Pump element 8 is marked by a red ring R.

Adjusting the delivery volume:

The delivery volume can be reduced to minimum of appr. 25% of the rated one.

Adjustment is to be done as follows:

Remove lock screw 7.

Adjust on adjusting nipple 7 the delivery volume required by using the wrench

contained in the scope of delivery.

Turning to the right will decrease the delivery volume, whereas

turning to the left will increase it.

The adjusting nipple will latch. Here, one latch equals 1/6 rotation of the adjusting

nipple.

When leaving the factory, the pump elements are set to maximum delivery volume.

Screw down lock screw 7 again.

4.5 Level monitoring (Ultrasonic sensor)

Technical data:

Operating voltage: 9 V ... 30 VDC

reverse polarity protected

No-load supply current: ≤80 mA

Class of protection: DIN EN 60529 IP67

Type of connection: M12x1, 5-pin,

Circular connector

Transducer frequency: 200 kHz

Operation

Ultrasonic sensors work maintenance free. Small amounts of dirt on the surface do not

influence function. Thick layers of dirt and cakedon dirt affect sensor function and therefore

must be removed.

Loading...

Loading...