PN-52886 (4/97)18

DEALER SERVICE

The information in this section is written for dealer

service personnel. The repair described herein

requires special skills and tools. If your shop is not

properly equipped or your mechanics are not properly

trained in this type of repair, you may be time and

money ahead to replace complete assemblies.

WARNING

! Before working underneath, carefully

read operator manual instructions , discon-

nect driveline, raise mower, securely block

up all corners with jackstands and check

stability. Secure blocking prevents equip-

ment dropping from hydraulic leak down,

hydraulic system failures, or mechanical

component failures.

! Keep all persons away from operator

control area while performing adjust-

ments, service or maintenance.

CAUTION

! Always wear relatively tight and belted

clothing to avoid entanglement in moving

parts. Wear sturdy, rough-soled work

shoes and protective equipment for eyes,

hair, hands, hearing and head.

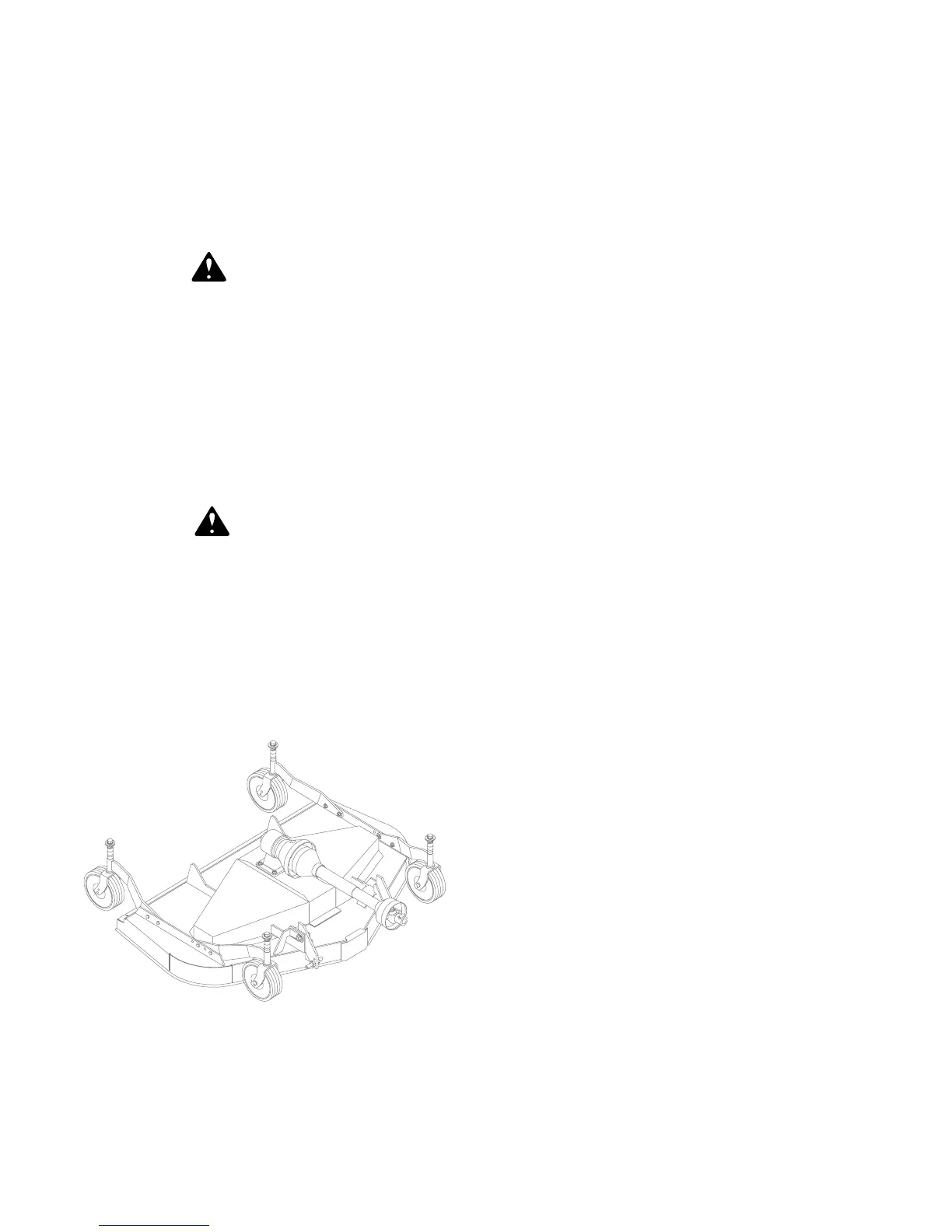

BLOCKING METHOD

(Figure 14)

CD4985VAR

X

X

X

X

Figure 14. Blocking Method

Do not work underneath mower unless it is properly

attached to the tractor and blocked securely. When

properly attached, the unit will be anchored to

minimize front to rear movement.

Raise mower completely, set tractor brakes, turn

engine off, remove key, block tractor wheels front and

rear, and disconnect mower driveline from tractor.

The only approved blocking device for this mower is

a jackstand with a load ratingof 1000 pounds or more.

Install one jackstand under each corner of the mower

(four total), before working underneath this unit.

When blocking, you must consider overall stability of

the unit. Just blocking under the unit will not ensure

your safety. The working surface must be level and

solid to support the loaded weight of the jackstands.

Test jackstands stability before working under any

portion of the mower.

BLADE SPINDLE REPAIR

Spindle repair requires special skills and tools. If your

shop is not properly equipped or your mechanics are

not trained in this type of repair, you may be time and

money ahead to use a new spindle assembly.

For reference, the grease fitting is in the top of the

spindle shaft.

Permatex 3D Aviation Form-A-Gasket

or equivalent

is recommended as a sealant.

Spindle Removal

Remove blade from spindle.

Remove belt from pulleys.

Remove jam nut and washers from top of spindle

shaft.

Disassemble split taper bushing (located on top of

pulley) by removing the two bolts and inserting them

into the threaded holes of bushing flange. Tighten

them alternately to remove split taper bushing.

Remove pulley.

Spindle Disassembly (Figure 15)

Remove bolts attaching spindle to mower frame and

remove spindle.

Remove grease fitting.

Place spindle assembly in press and press shaft

down through housing.

Remove seals from housing.

Remove bearing cups from housing by placing a

punch in slots provided and driving out. Alternate

punch positions from side to side. Take care to

prevent housing damage.

Permatex 3D Aviation Form-A-Gasket is a registered

trademark o f the Permatex Corporation.

Loading...

Loading...