PN-52886 (4/97)16

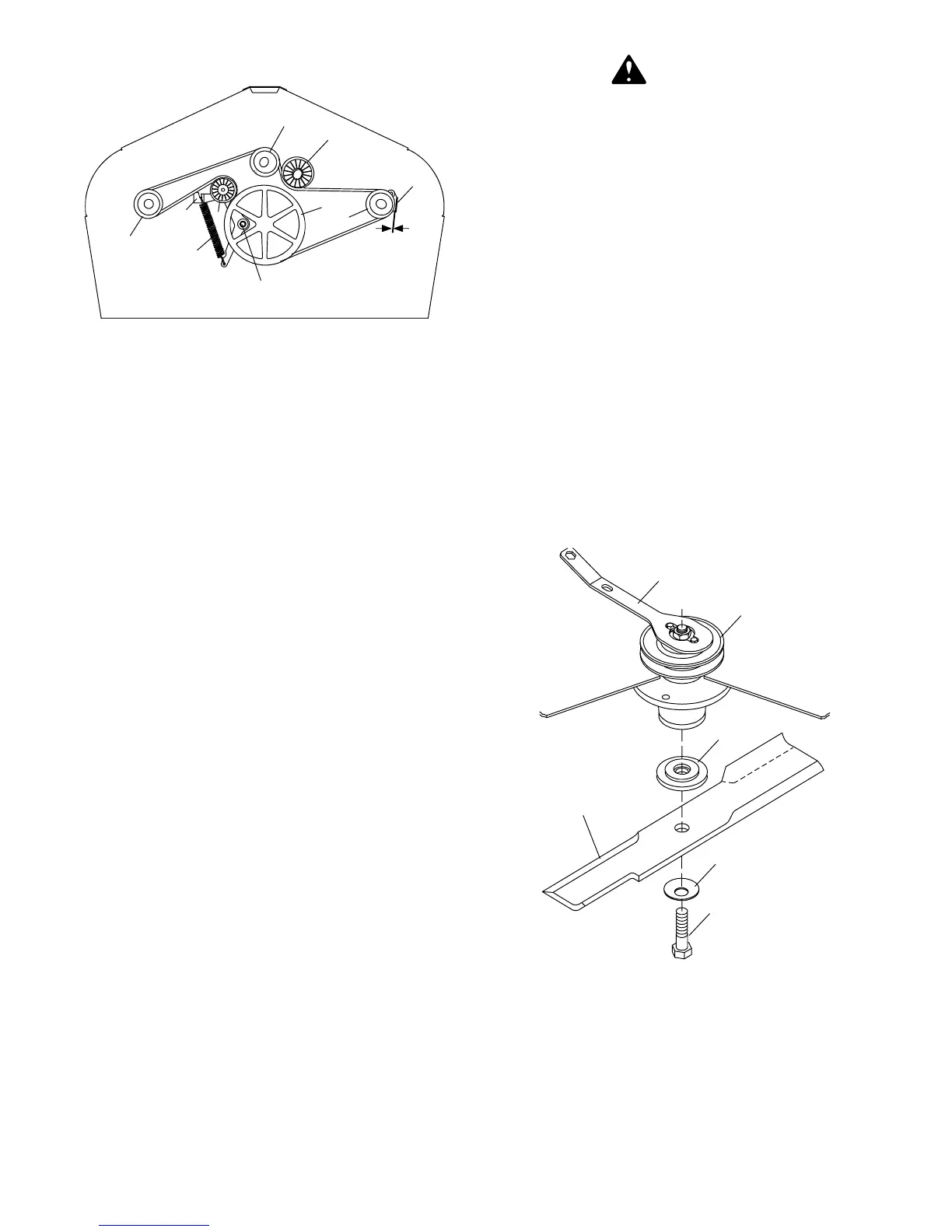

BELT REPLACEMENT (Figure 10)

CD4989VAR

G

B

A

C

D

F

E

1/8″

H

I

IDLER ARM PIVOT

Figure 10. Belt Routing

One of the major causes of belt failure is improper

installation. Before a new belt is installed, check

pulley shafts and bearings for wear. Check pulley

grooves for cleanliness. Make sure spindles turn

freely and without wobble. If grooves require cleaning,

moisten a cloth with a non-flammable, non-toxic

degreasing agent or commercial detergent and water.

Avoid excessive force during installation. Do not use

tools to pry belt into pulley groove. Do not roll belt over

pulleys to install. This can cause hidden damage and

premature belt failure.

IMPORTANT

! Use care when installing or removing

belt from spring-loaded idler at step 5.

Springs store energy when extended and,

if released suddenly, can cause personal

injury.

1. Disconnect idler spring from deck lug “I”.

2. Slide belt underdrive pulley “A”andoveridlerarm.

Position belt around drive pulley “A”.

3. Loosen bolt holding belt guide “G” and swing it

awayfrompulley “B”.Routebelt aroundpulley“B”,

idler “C” and pulley “D” as shown.

4. Make sure belt is on drive pulley “A”, route around

idler“F”,andconnectidlerspringtolug“I” ondeck.

5. Grasp belt between spindle pulley “E”, spring

loaded idler “F” and spindle pulley “D”. Pull spring

loaded idler with belt to obtain enough belt length

torouteitoverpulley“C”.Makesurespring-loaded

idler pivots freely with belt installed.

6. Adjust belt guide “G” to provide 1/16” to 1/8”

clearance from belt. Tighten bolt to 85 lbs.-ft.

BLADE SERVICING

Inspect blades for condition and proper installation each

time before operation. Replace any blade that is bent,

excessively nicked, worn or has any other damage.

Small nicks can be ground out when sharpening.

WARNING

! Before dismounting tractor or perform-

ing any serv ic e or maintenance, disengage

powerto implement, lowerthe 3-pointhitch

and all rais ed components to the ground,

operate valve levers to release any hydrau-

licpressure,setparking brake, stopengine,

remove key, and unfasten seat belt.

! Keep all persons away from operator

control area while performing adjust-

ments, service or maintenance.

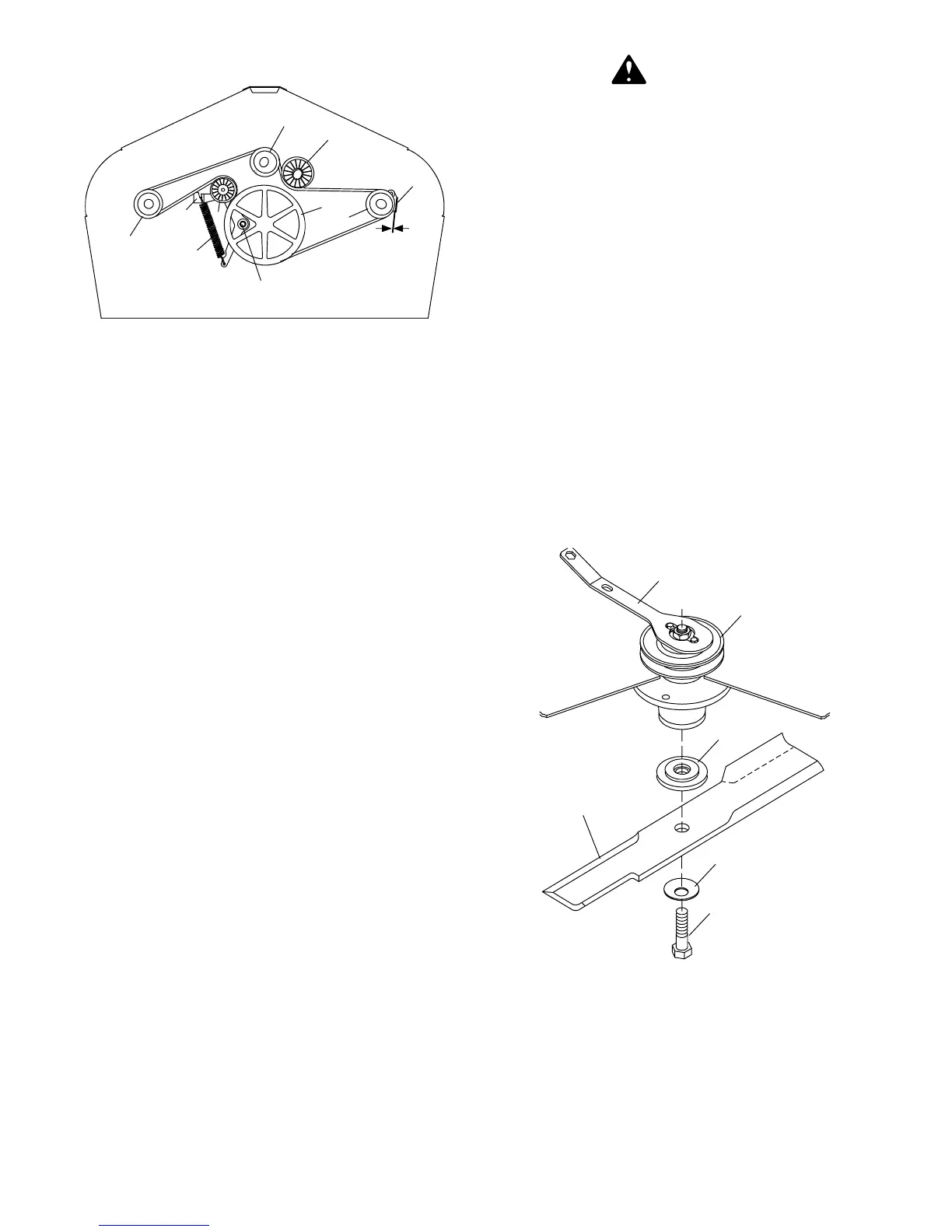

Blade Removal

RD6000 (Figure 11)

Remove belt shields.

Install spindle lock wrench (1) onto spindle pulley as

shown. Remove cap screw (6) which has RIGHT HAND

THREADS. Remove cup washer (5) and blade (4).

Shoulder washer (3) will not normally come off unless

intentionally removed.

CD4988A

1

2

3

4

5

6

1. Spindle wrench

2. Pulley

3. Shoulder washer

4. Blade

5. 5/8 x 3 Cup washer

6. 5/8 NC x 3-1/2” Hex head cap screw GR5

(RD6000)

Figure 11. Blade Installation for

RD6000 SN 793923 and prior

(Rev. 6/28/01)

Loading...

Loading...