19PN-52886 (4/97)

CD5061

2

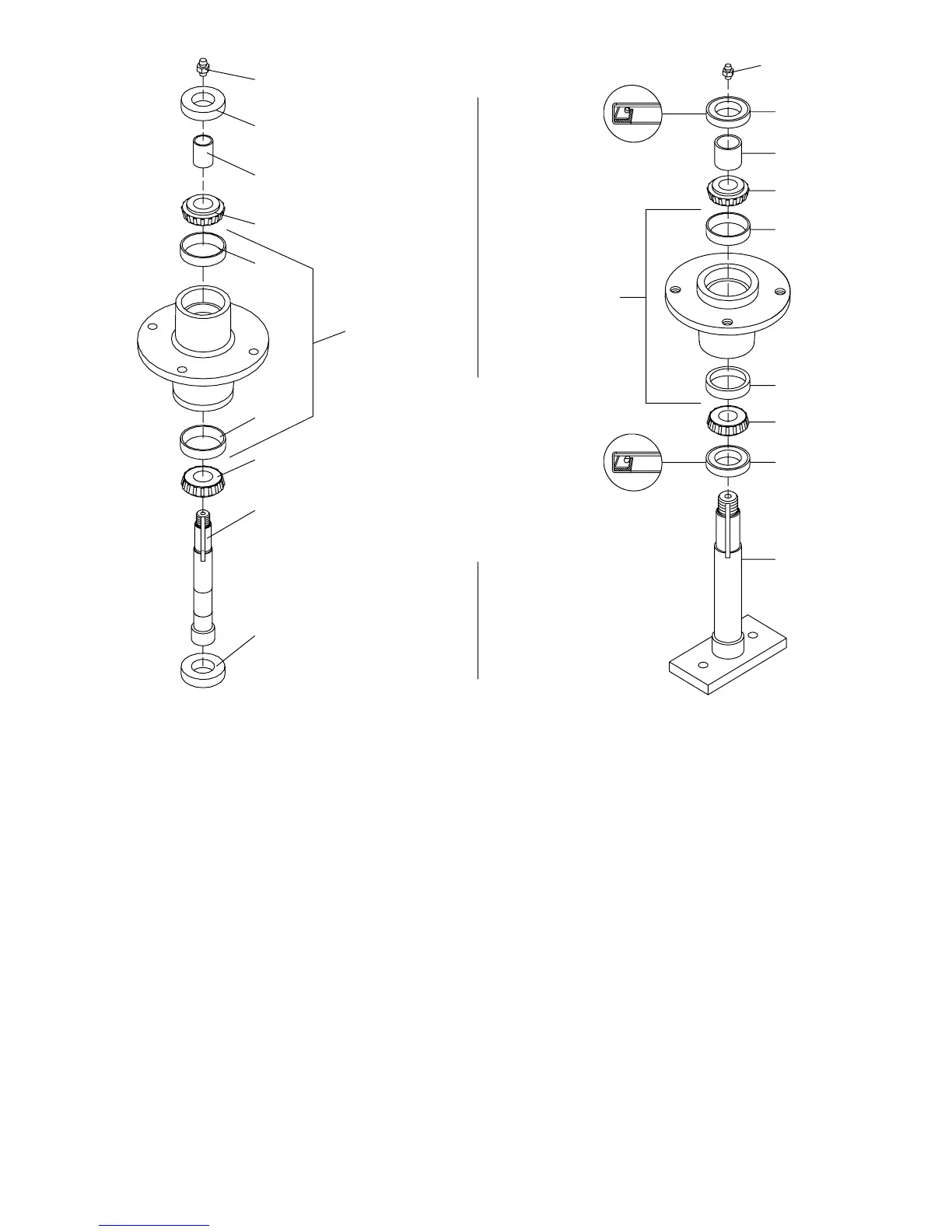

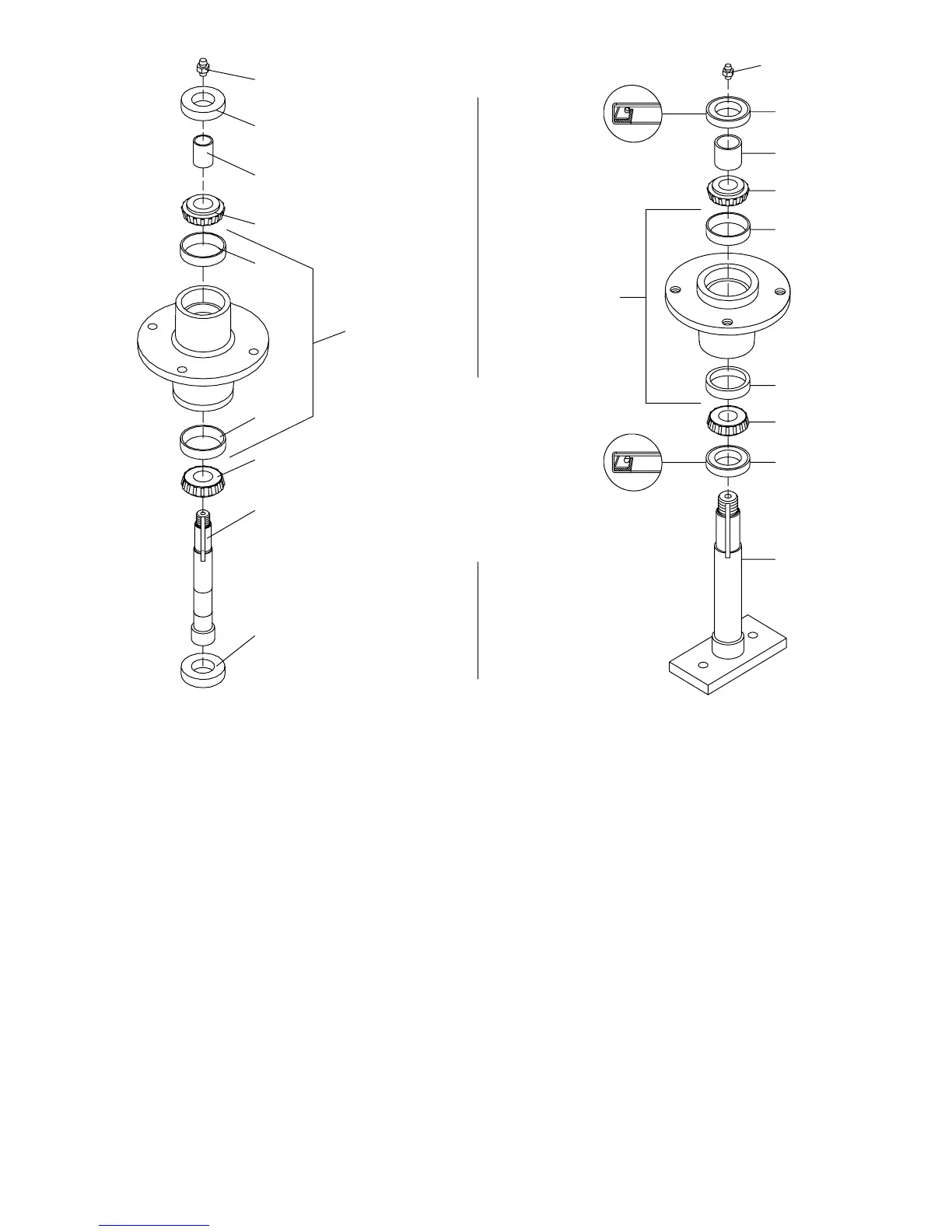

SEAL LIP

1

SEAL LIP

2

3

4

5

4

5

7

6

CD4107

1

2

3

4

5

6

5

7

2

4

1. Grease fitting

2. Seal

3. Sleeve

4. Bearing cone

5. Bearing cup

6. Spindle housing

7. Spindle shaft

RD6000 after SN 793923

RD7200 & RD8400

RD6000

SN 793923 and prior

Figure 15. Blade Spindle Assemblies

Spindle Assembly (Figure 15)

Bearing cones and cups are designed to work

together. It is important to position them so bearing

cone taper mates with cup taper.

Lubricate new cups with a light oil. Place them in

spindle housing so they will mate with bearing cones.

Cups and cones are a press fit to minimize wear.

Seat cups securely with a press or place a large drift

in the flat lip and drive them into housing until cup

seats against machined shoulder of housing.

RD6000 Spindles Only

Place bottom bearing cone onto spindle shaft with

taper positioned to mate with cup. Press onto shaft

and seat on bottom shoulder of shaft.

Insert shaft and bearing through bottom of housing.

Fill housing cavity with a medium grade grease.

Install top bearing on shaft to mate with top cone.

Apply a thin coat of Permatex to shaft area where

sleeve will seat.

Install sleeve on shaft and press sleeve and bearing

into housing until all free play is removed and there is

a very light drag on bearings (similar to adjusting front

wheel bearings on an automobile). Check by spinning

spindle. It should turn freely.

Be careful not to overtighten bearings. Proper bearing

adjustment is essential to good bearing life.

Should you overtighten bearings, hold spindle hous-

ing and rap spindle shaft with a lead hammer.

IMPORTANT

! Improper positioning of seals can

cause seal damage.

Proper seal installation is important. An improperly

installed seal will leak and could cause bearing

failure.

(Rev. 4/12/01)

Loading...

Loading...